A reader favorite, our wood closet shelving plans are easy to build, easy to customize, and budget friendly! It costs about $20 a linear foot (our 10 foot closet cost $200) to build. You'll love our free step by step plans with full diagrams and lots of reader submitted photos.

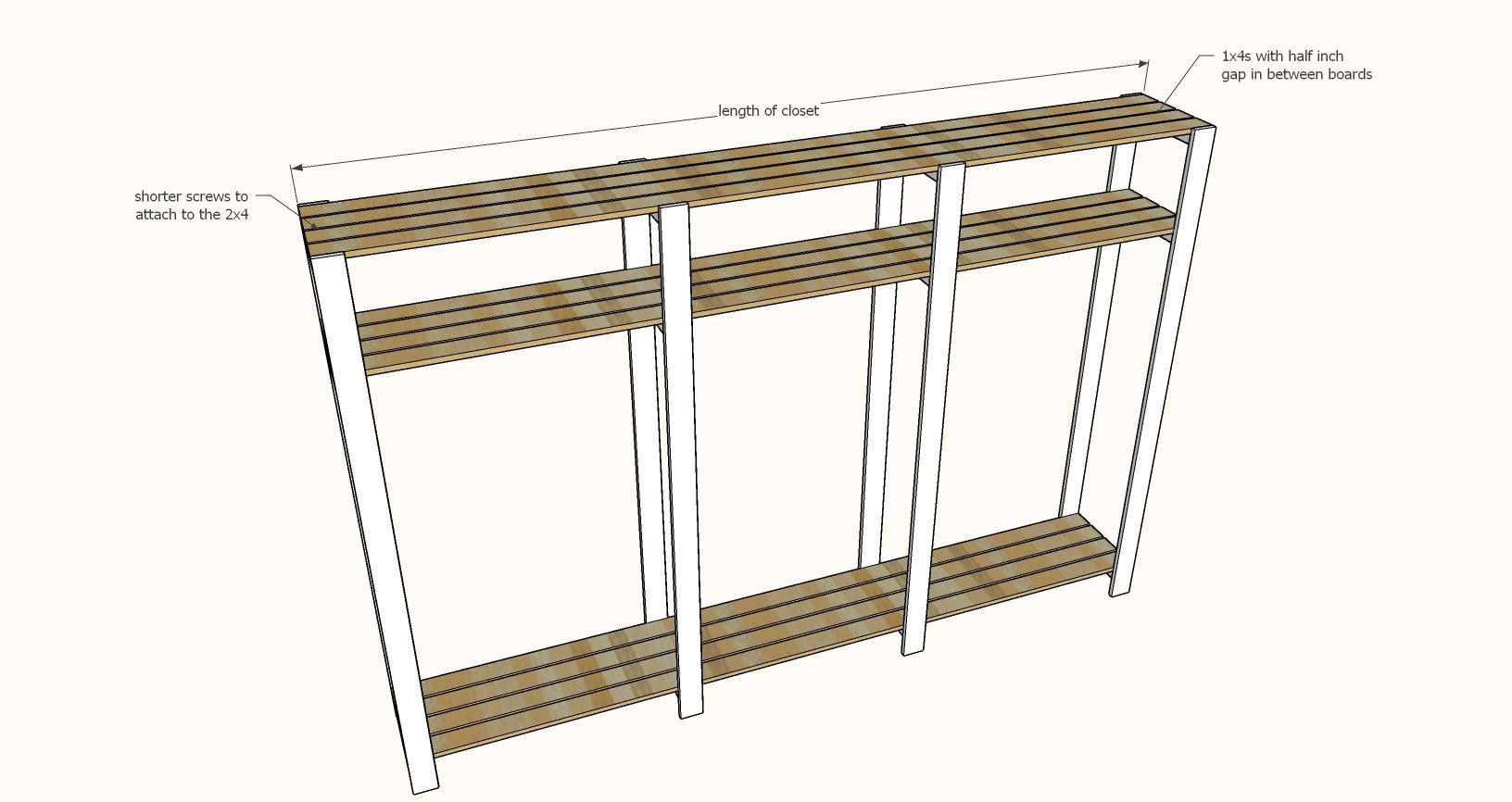

Note that this closet is most likely too tall to fit inside doorways and will need to be assembled in the closet (after you make the leg supports). If your closet is really tight, you may wish to shorten the entire closet by a few inches (measure you doorways).

Preparation

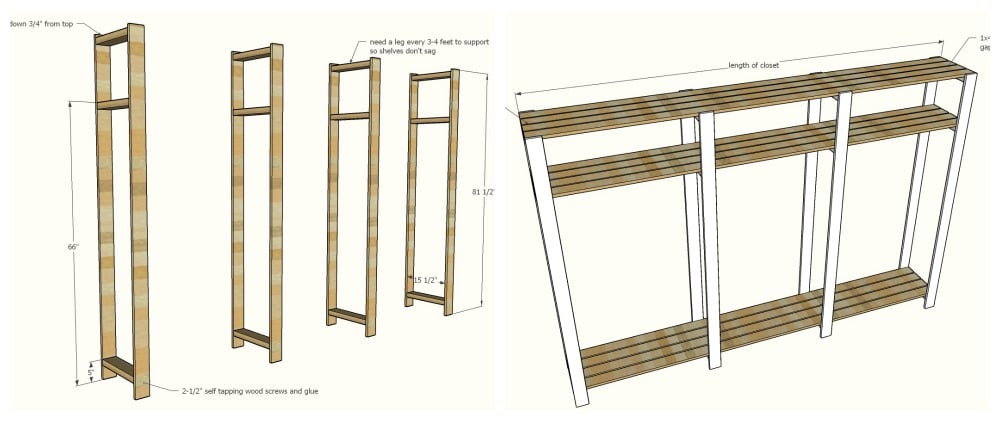

PER LEG SUPPORT (You'll need at least two leg supports, and additional leg supports every 3 feet or so)

- 2 - 1x4 @ 8 feet long (for the legs)

- 4 feet of 2x4 for the legs with closet rods and upper shelves, 8 feet of 2x4s for legs with closet rods, upper shelves AND and extra shelf supports

- I'd buy one extra 2x4 for things like supporting the closet rod (if not using the pipes) and for cutting around knots, cracks, splits etc

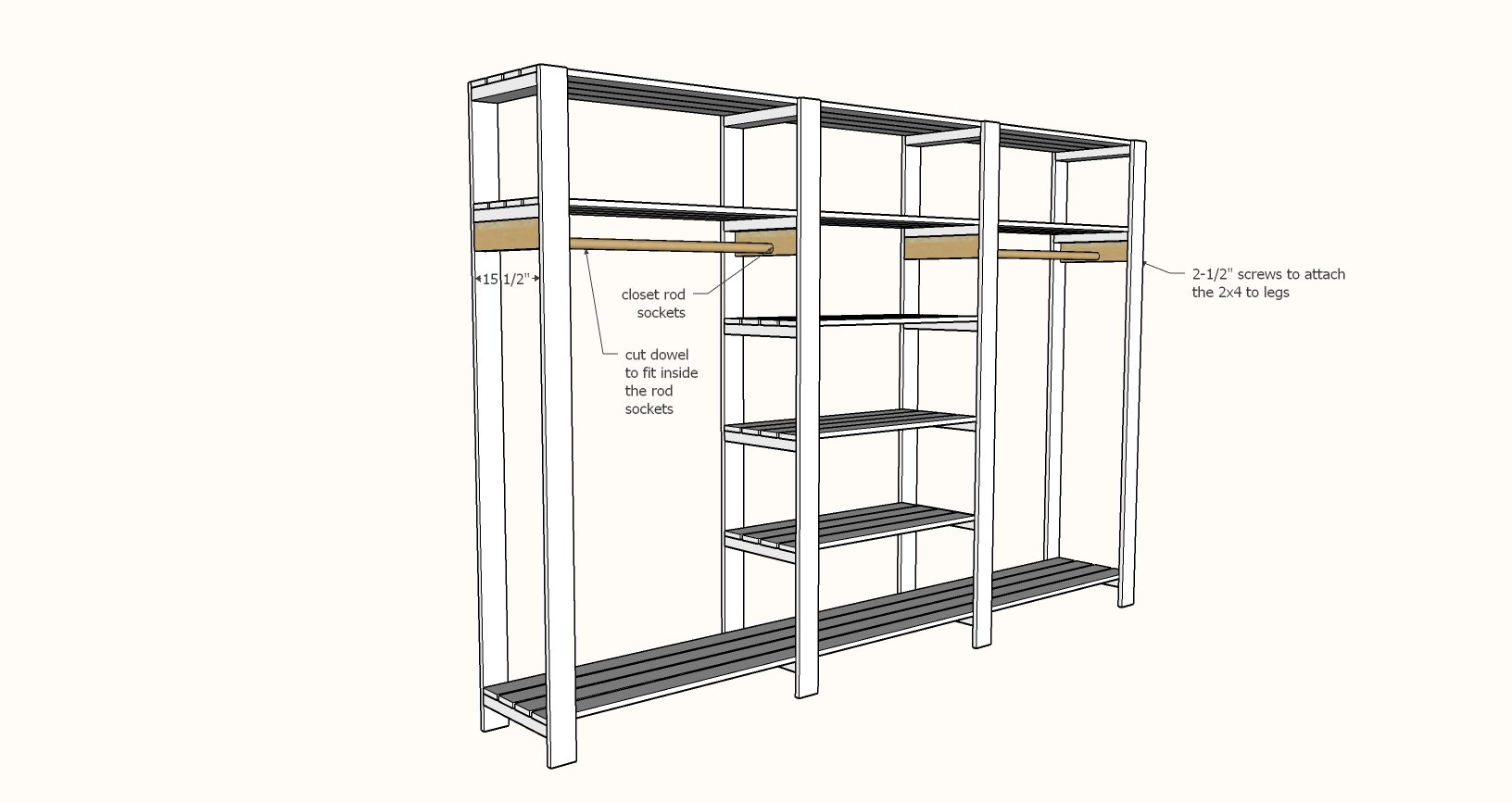

- 2-1/2" self tapping screws for attaching the legs to the 2x4 ends, two per joint

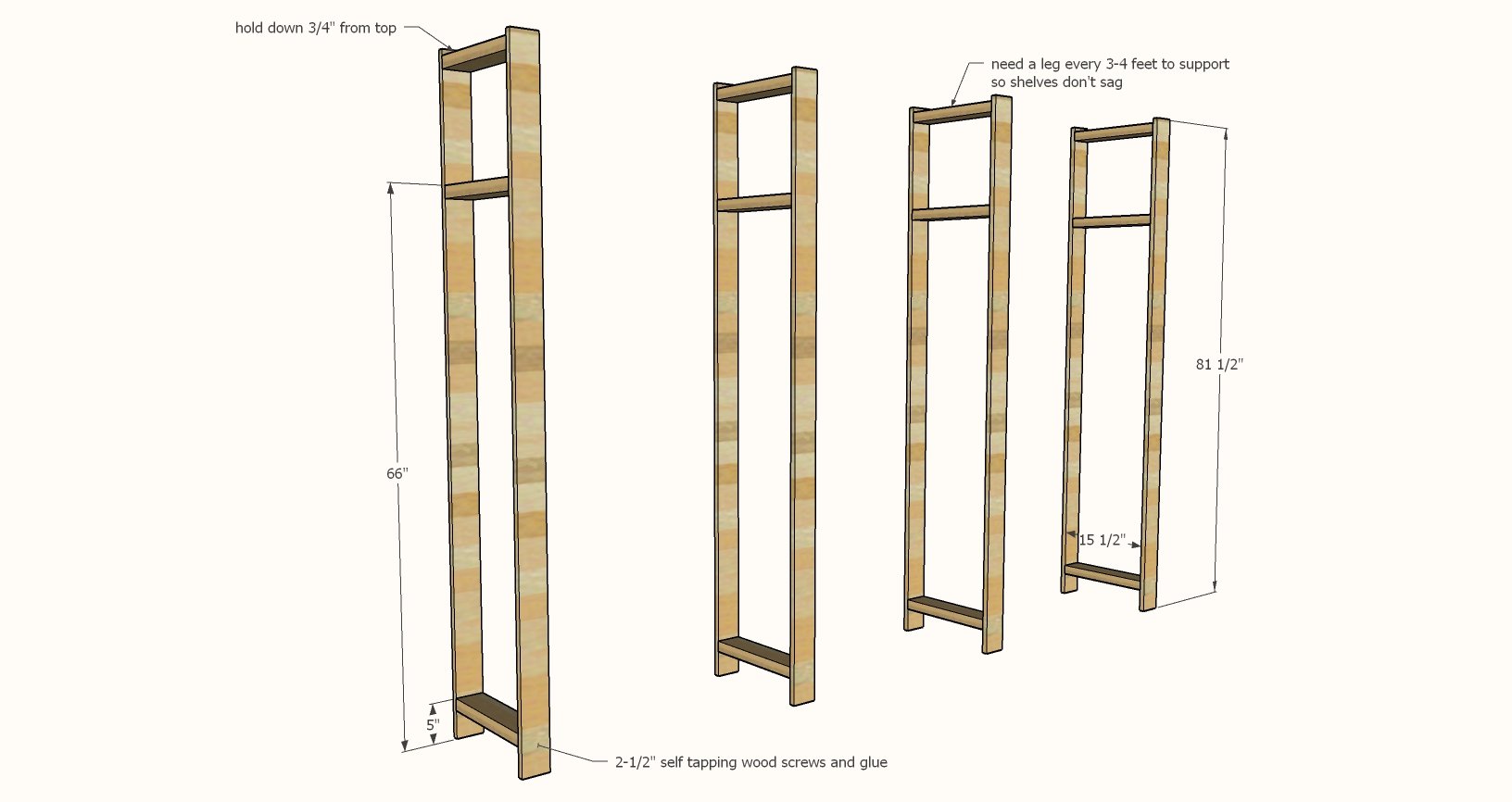

SHELVES

- 4 - 1x4 @ length of closet PER SHELF

- Additional 1x4s for smaller shelves if using

- 1-1/2" self tapping screws for attaching shelving or brad nails (recommend two per joint)

Wood stain or paint - I stained all of my boards first, before cutting. I let them dry overnight. After completing the project, I touched up unstained areas (cut ends).

PER LEG SUPPORT

- 3 - 2x4 @ 15-1/2" (shelf supports - make sure you measure your pipes first to figure how deep the closet needs to be to work with the iron pipe closet rods)

- 2 - 1x4 @ 81-1/2" (legs - you may wish to shorten these to pass through doorways)

SHELVES

- Per each full length shelf - 4 - 1x4s cut to length of closet

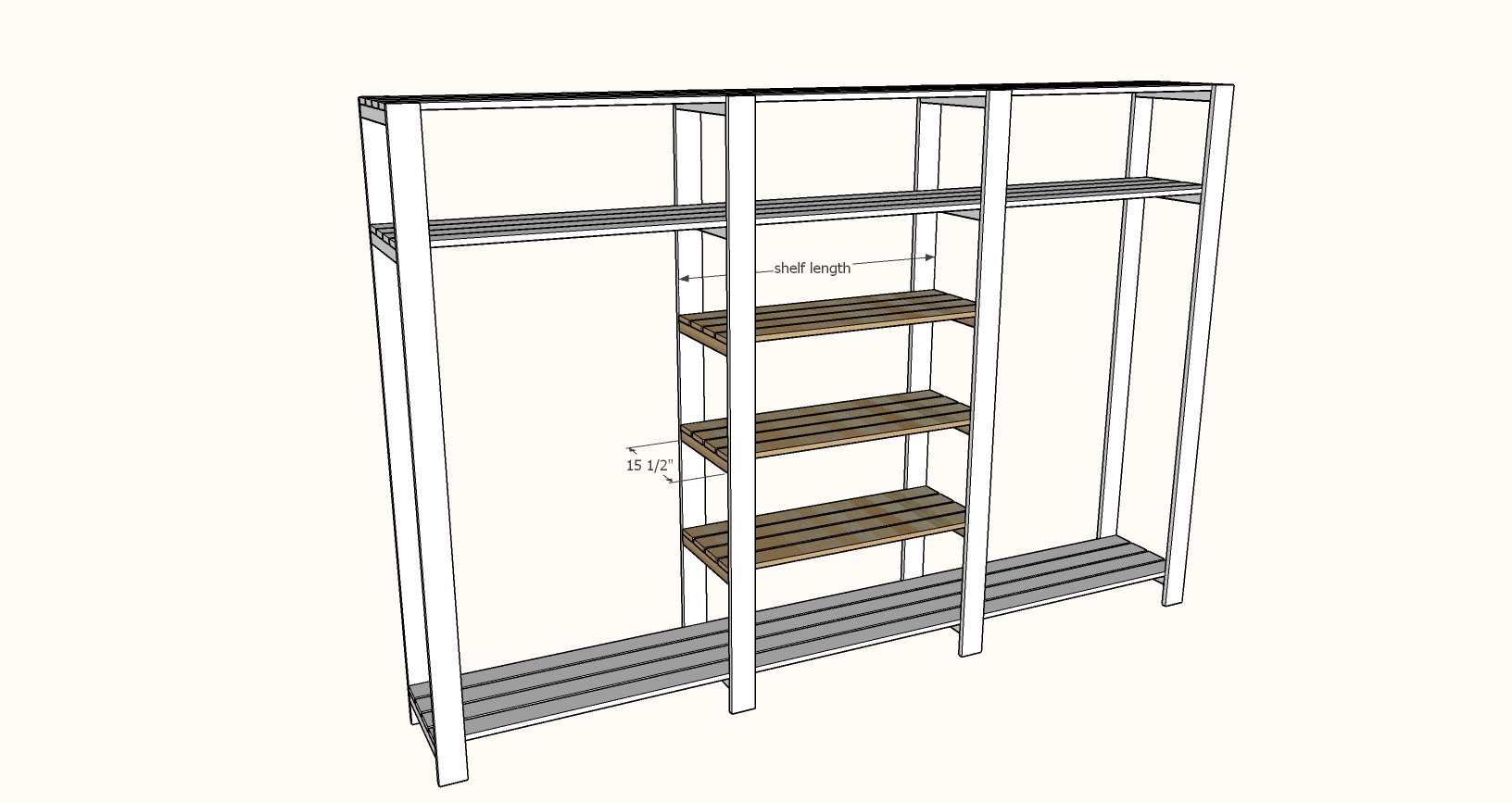

FOR EACH SMALLER SHELF

- 2 - 2x4 @ 15-1/2"

- 4 - 1x4 cut to length of smaller shelf

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 1

Step 2

I cut all my shelving to the length of the closet. Then I threaded two shelving boards on bottom shelf and two on second to top shelf.

I screwed the shelving boards to the outside leg supports, flush to the inside of the legs (will come back and add the middle shelving boards). Once the two outside leg supports were screwed down, I used a level to place the remaining two legs, with the closet rod determining where the legs should go.

Then I added the remaining shelving boards, screwing those down. Attach the outer shelving boards first, then evenly space the middle two shelving boards. I used 1-1/2" screws here. Once everything was tied in, it was pretty secure, but just for added security, I also screwed the shelving unit to the walls to prevent racking or forward tipping.

Step 3

Step 4

We love the look of the iron pipes, but it is expensive.

Here's a cheaper way that will function just the same.

Add more 2x4 @ 15-1/2" wherever you want a closet rod, but attach so the 2x4 runs tall, not flat and wide.

Then use closet rod sockets and wood closet rods cut to length in between the 2x4s run tall.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

brookifer86

Thu, 09/18/2014 - 07:41

Wowza!

This closet is SO beautiful! You're right, I can totally see this as a display shelf in an upscale store. Once again you hit it out of the park. Now I'm eyeballing my home wondering if there's a spot to fit this...

vjdoro7

Thu, 09/18/2014 - 10:45

Beautiful

I love the look of your storage unit. I have made similar things in the past. Unfortunately mine do not look as nice because they are loaded with stuff. Looks more like art when it is sparsely used and the clothing is sort of monochromatic. Very nicely done and artistically presented.

dewdrop

Thu, 09/18/2014 - 11:31

Love the look of this!

Maybe I am that one person! I've been debating building your other closet organizer but just haven't been certain I could haul around and install it due to the weight of it. This one will do the trick and I love the industrial look! Thank you!

mike0mike

Thu, 09/18/2014 - 12:19

Noob question

What type of wood 1x4 did you use?

In reply to Noob question by mike0mike

Jacob White

Thu, 09/18/2014 - 12:30

Hi - just those cheapo

Hi - just those cheapo whitewood/pine boards and 2x4s :)

kmatt55

Sat, 09/20/2014 - 18:09

This is brilliant and

This is brilliant and stunning! Love it!

Liam

Sun, 10/19/2014 - 17:51

Lumber Dimensions

Are those true 1x4s or 3/4x3.5s?

Wondering if 3/4" thick would be strong enough, especially once weighed down with items.

And did you just use regular 2x4 studs?

Thanks!

davidduncan0

Mon, 12/29/2014 - 16:17

Dimensions

Liam, I hope it's ok for me to answer.

Any lumber you get from the home stores are going to have the smaller measurements, it's just easier to say "1x4". As far as being strong enough, the plan calls for 4 boards across, so the weight will be distributed, with each board taking 1/4 of the weight. Hope this helps.

David

Backinservice

Tue, 11/25/2014 - 10:53

Nice project

I like it was suprised to see no Kreg pocket holes! But does that mean pocket hole joinery isn't strong enough for storage shelves? If it is, what are the best methods for heavy shelves?

davidduncan0

Mon, 12/29/2014 - 16:22

pocket holes

Back, (or is it Service?)

I think the industrial look to the shelf lends itself to the lack of pocket holes. As far as being strong enough, I built the "industrial rolling shelf" for my garage using the Kreg, and it's loaded to the hilt with no issues. I think this one was designed to be quick and easy. Pocket holes are great but they do add a lot to the time to build. Just my opinion. Thanks, David

charid

Tue, 12/30/2014 - 11:30

nice

great for the laundry room.

mrsajsmith

Mon, 02/23/2015 - 15:13

price?

Where are you buying your materials? I priced this out as shown, at 8' length. My price is $400, not including stain or screws, making it over double what you said it cost you. And yes, this is with the cheapest wood at the store. Please let me know as I'd like to build this while keeping costs down.

jpurp

Sat, 01/16/2016 - 23:48

Price

What price were you quoted on 2x4's and 1x4's? None of them should be more than $3.00 each and that would be what I pay in Canada where everything is more expensive and I'm rounding up the price. Any big box store will carry an inexpensive whitewood. Did you go to a specialty store and get quoted on a nicer type of wood?

Sarine

Thu, 11/05/2015 - 04:46

Advise to get cedar wood planks?

I'm new into the woodwork world and was wondering if cedar wood planks work for this project?

Sarine

Thu, 11/05/2015 - 08:57

Closet width? 15 1/2 inch instead of 24"?

Shouldn't a closet be at least 24" deep? From what I understand from the plans, this closet is only 15 1/2". Can someone please explain it to me?

In reply to Closet width? 15 1/2 inch instead of 24"? by Sarine

JoanneS

Thu, 11/05/2015 - 13:43

Closet system dimensions

Hi Sarine,

This plan is for the organizer that goes inside the closet. Most of the organizer systems you find for sale are about this depth. If you add in the thickness of the front and back boards in this plan, (2 x4's are1.5" thick) to the 15 1/2" shelf, it makes the depth at 18.5 inches. In a 24 inch deep closet that leaves you with a few inches of space in front of the organizer inside the closet. DIY is so wonderful because you can customize the piece to fit your individual needs. You could change the depth by adjusting the size of the side pieces and the shelves. If you are putting this inside of a closet, the depth in the plan will work great for you! Happy building! :) Joanne

Phoenix builder

Wed, 02/17/2016 - 14:24

Industrial Closet

As I'm getting ready to tackle this project, I just have a question about the project. The self tapping screws , what is the gauge of them. Are they #8, #9 or #10?? Does it matter the gauge?

Thanks!!

[email protected]

Tue, 07/26/2016 - 08:05

Great DIY Closet

We will be renovating our master bedroom entirely and I wanted to build our new master closet myself and wanted a rustic look. So glad I found this project of yours. I will be doing this for sure. Love how you made it simple and rustic.

Do you have any ideas for covering up a window that may be behind out bed? I will have some old shutters I was thinking of using. Thanks

G Madore

Maine

benjaminrogers

Thu, 08/03/2017 - 07:35

Build around a Corner

Using this design how would you construct it to wrap around the corner? We live in a 1920's home and there are fireplace bump outs in the bedrooms and little to no closet storage.

Thanks,

Ben

KW78

Tue, 01/16/2018 - 07:53

Doors

I am thinking of building a bigger shelfing system covering the entire wall. Are there ways to add doors to keep the dust away?

kaprince

Sun, 09/15/2019 - 17:26

Closet X 2

Can't wait to try this!

Dland1961

Fri, 12/27/2019 - 05:34

Closet

I built this for a friend. It came out great! Very solid.

Chelsea Burns

Tue, 01/07/2020 - 10:29

Deeper possibility?

Hi! Do you think these plans would work if the shelves were about twice as deep, 30"? Or would the bracing start to be unstable and/or sag? Thanks!

Debramer1

Sun, 08/16/2020 - 00:53

New house

New house

kbaumer

Wed, 09/23/2020 - 09:02

What is the length of this…

What is the length of this shelf?

mike2k

Tue, 09/29/2020 - 09:32

Pictured closet length?

Curious what the length of the closet pictured is. I assume 10 feet or so? Assuming legs need to be at least 3 feet apart, but the center shelves look like they are less than 3 feet in length, so 8 total length maybe?

KeyserSose78

Thu, 11/05/2020 - 09:25

I found a couple of shower…

I found a couple of shower curtain rods at a garage sale for $1 each and used those to cut down cost. I built the whole project for around $80. Thanks for the plans, my wife is very happy with her new shelves and hanger space.

TryDoFix

Sat, 12/26/2020 - 19:09

Adding doors?

Exactly what I was looking for! If I wanted to add a sliding door to the whole closet, do I need to add one more brace outside and hang the door plus track there? Has anyone tried to add doors?

hauxy

Sat, 01/09/2021 - 08:14

Can we add a sliding door?

Yes- I have the same question. I have a busted up Ikea closet I’m getting rid of, but want to recycle the sliding mirror door and would like suggestions on how best to add it (or some form of sliding door) to this system.

The Winging-it Wife

Wed, 06/09/2021 - 08:34

Tweaked measurements and love

Did cry in frustration that my first-step frames were not square when I lined them up with each other. But used a temporary cross bracing to make them line up the. The shelving boards did the rest! I deepened the initial plans by 2 inches from 15.5” to 17.5” as I didn’t want the hanging clothes to stick out at the shoulders and I’m glad I did! That meant the shelving boards had about a 1 1/8” space in between. The three shelves in the “tower” side I spaced 16” from the bottom of the 2x4 shelf support piece to the top of the next 2x4. I only did that with the with the bottom four shelves. I have baskets that are 13.75”/16.5”/10.25” and they fit perfectly on those shelves.