Free plans to build a kitchen island with X sides, inspired by Pottery Barn Hamiltion reclaimed wood kitchen island!

Preparation

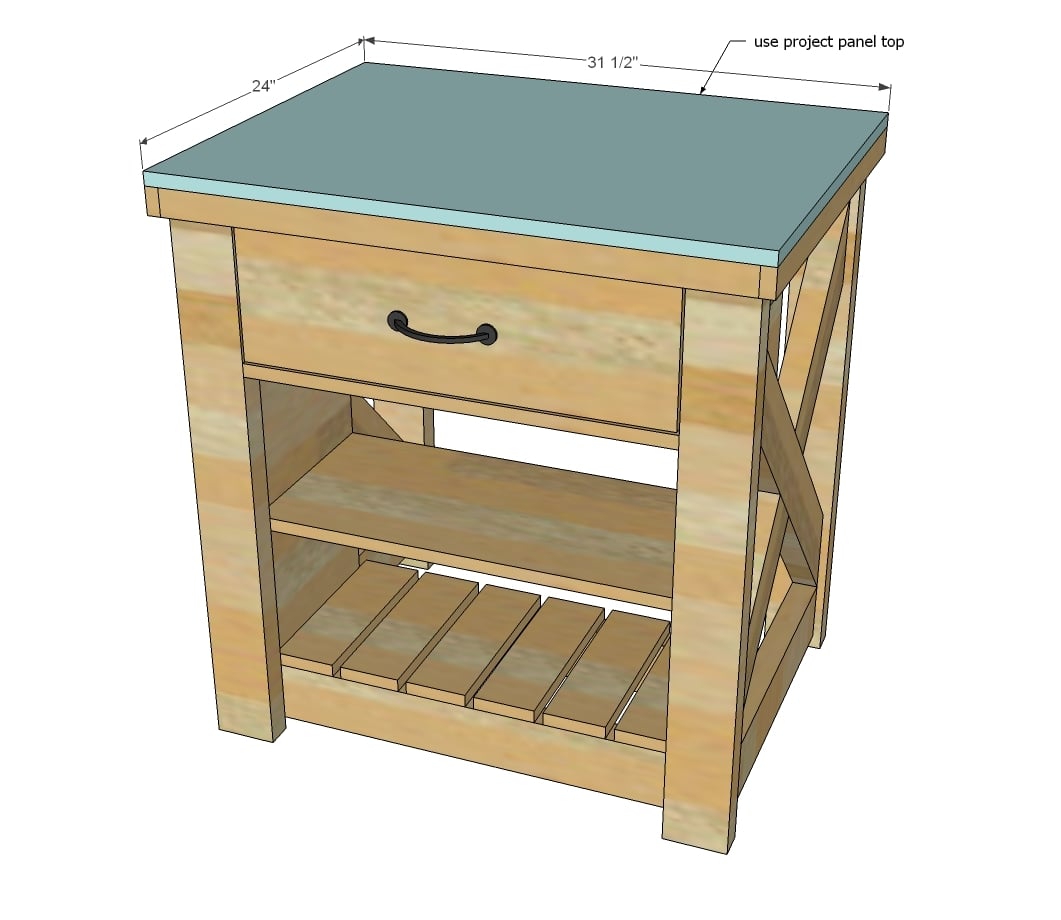

1 - Project Panel 24" wide x 32" long

4 caster wheels with overall clearance of 3"

1 handle

4 - 2x4 @ 8 feet long

1 - 1x4 @ 6 feet long

1 - 1x12 @ 8 feet long

1 - 2x2 @ 2 feet long

2 - 1x2 @ 8 feet long

1 - 1x6 @ 8 feet long

1 - 1x8 @ 2 feet long

1/2" plywood piece 10 1/2" x 19 3/4" (for drawer bottom)

CUT LIST

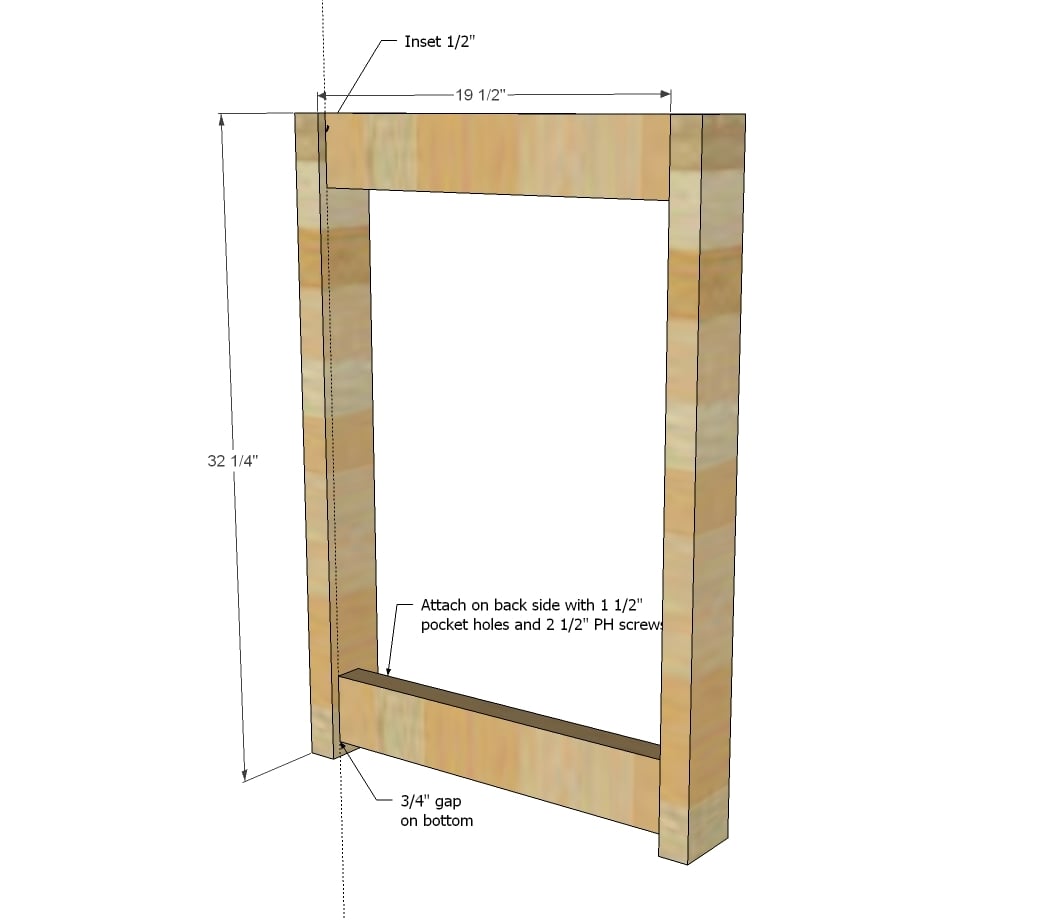

LEGS

4 - 2x4 @ 32 1/4"

4 - 2x4 @ 19 1/2"

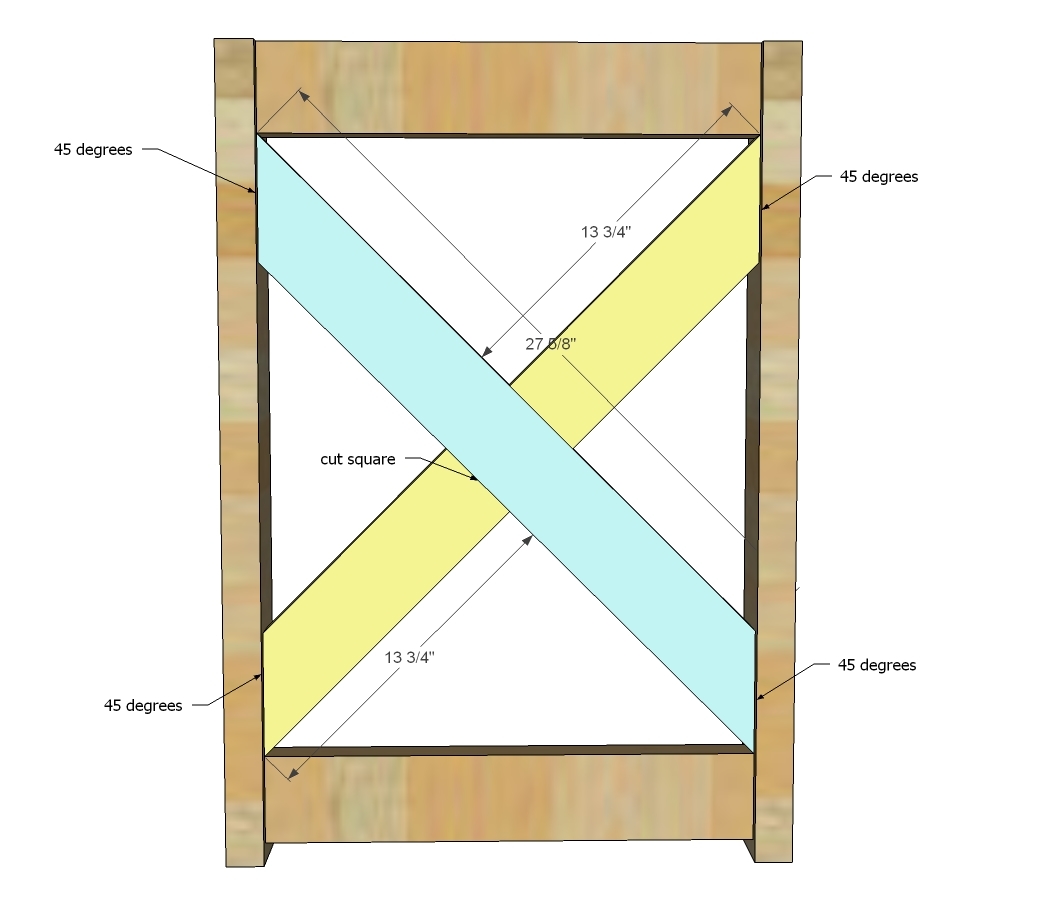

2 - 2x4 @ 27 5/8" - both ends cut at 45 degree angle, ends ARE parallel

4 - 2x4 @ 13 3/4" - one end cut at 45 degree angle, long point measurement

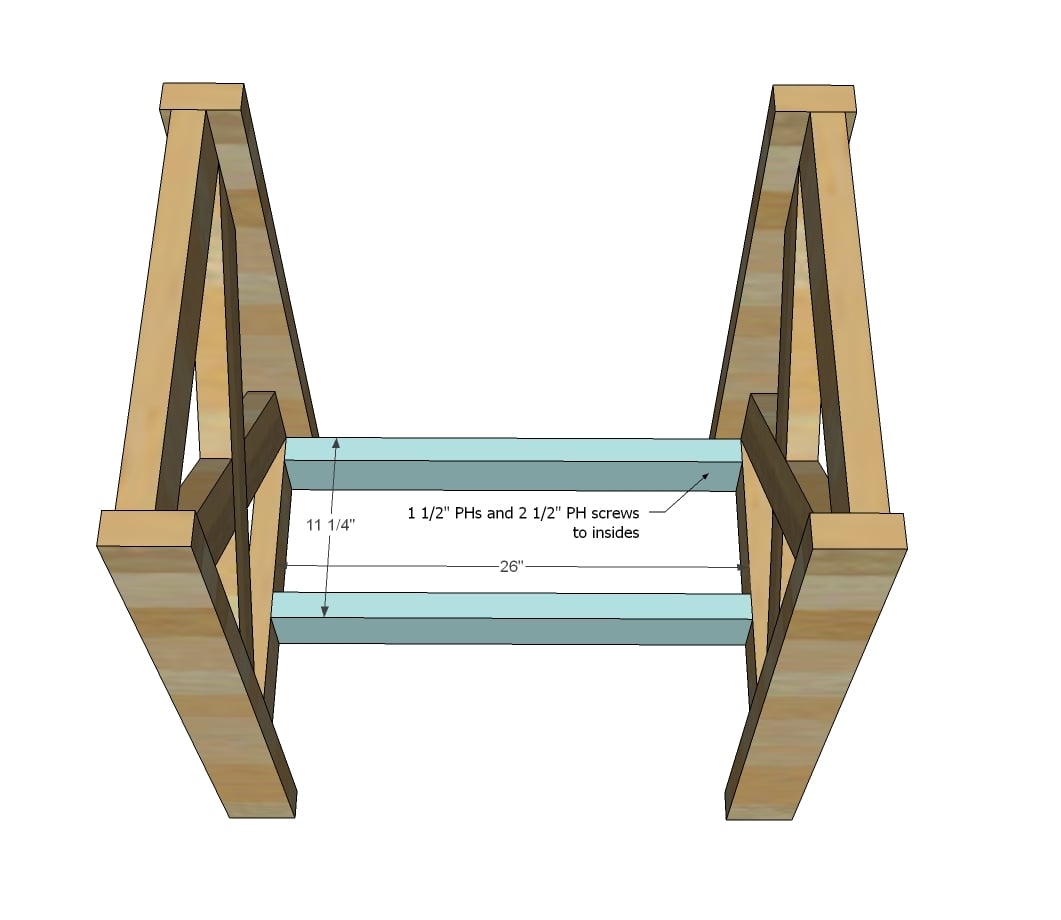

MIDDLE

2 - 2x4 @ 26"

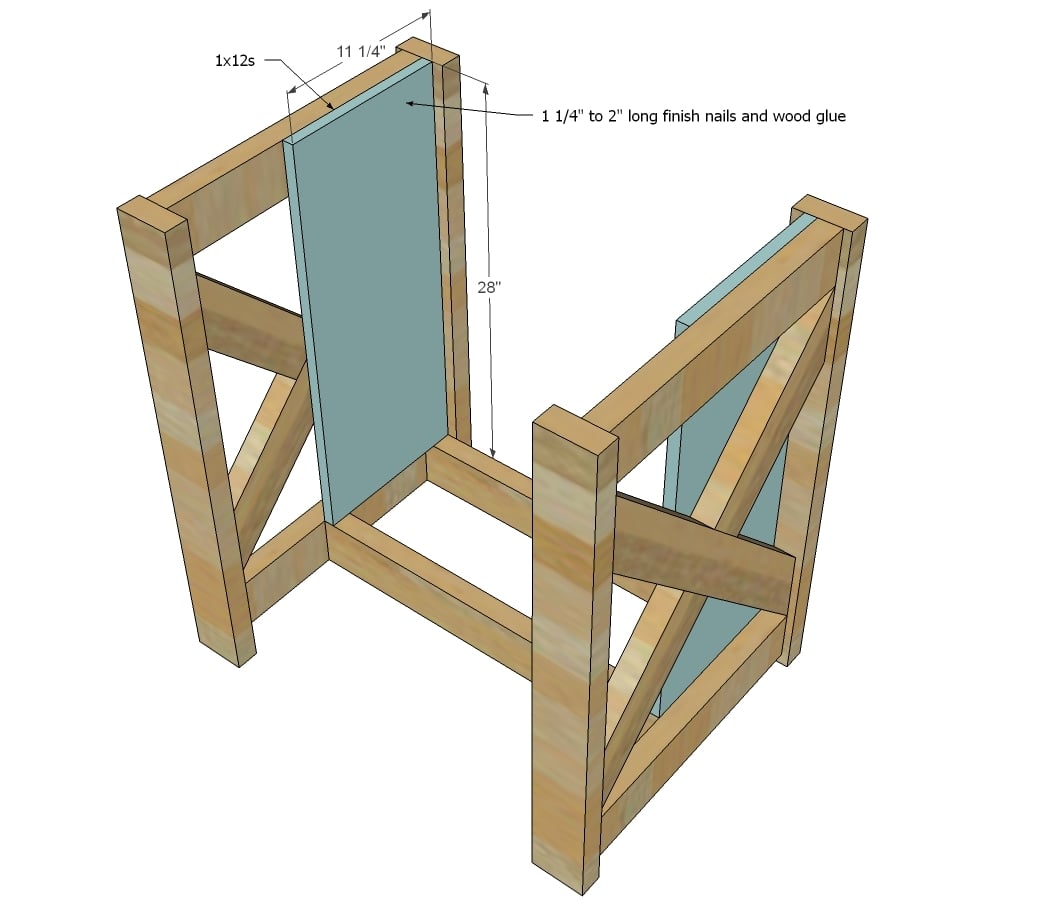

2 - 1x12 @ 28"

6 - 1x4 @ 11 1/4"

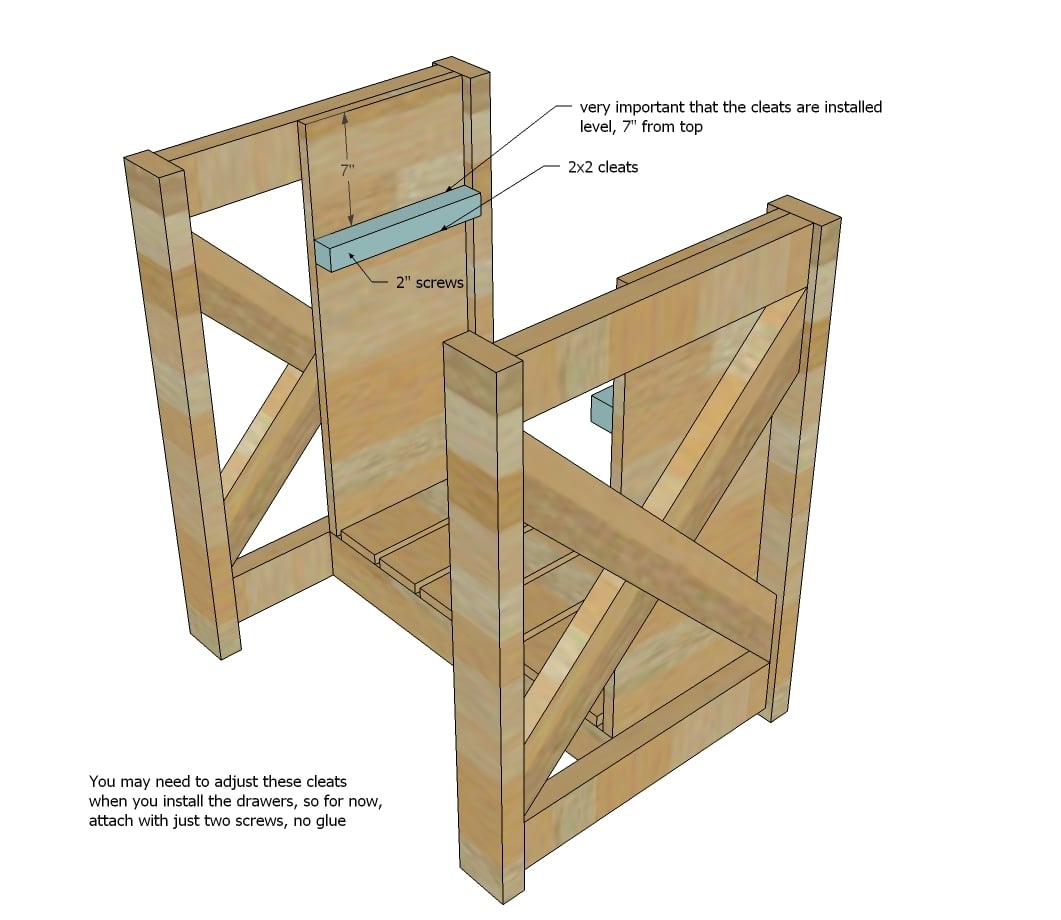

2 - 2x2 @ 11 1/4"

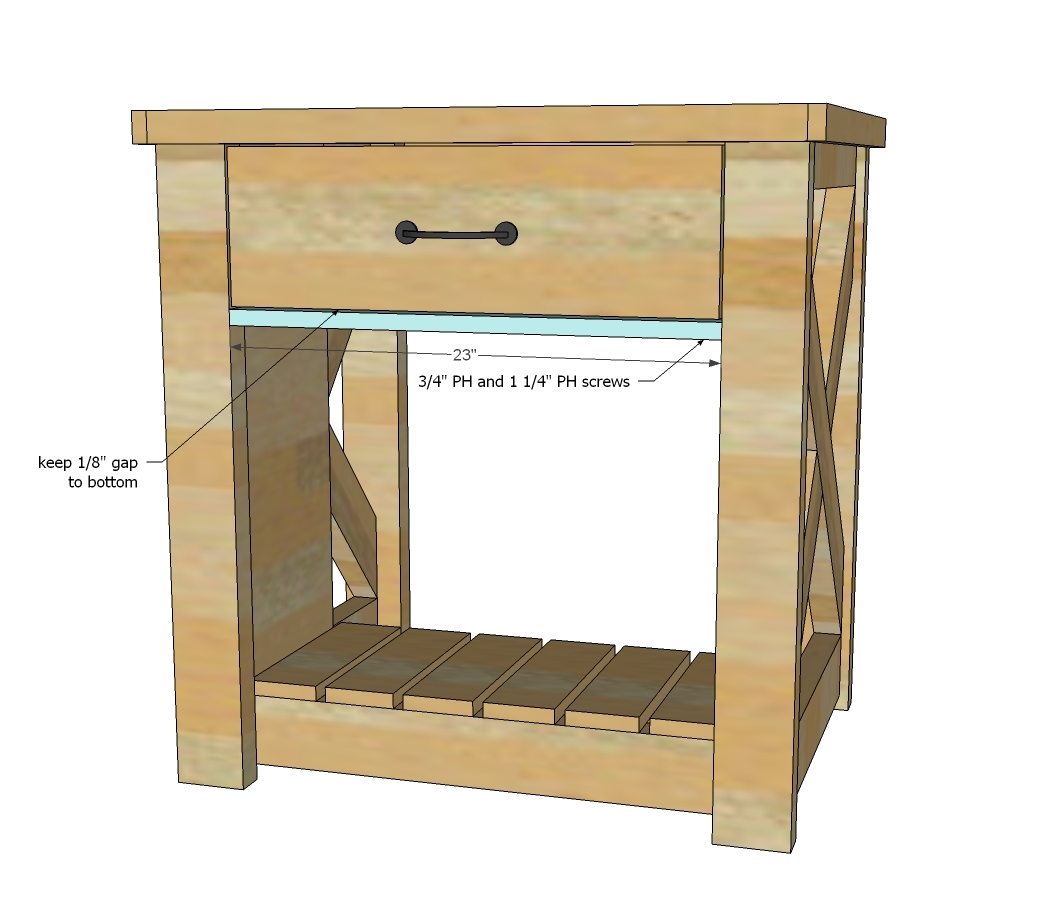

1 - 1x2 @ 23" (drawer trim)

1 - 1x12 @ 24 1/2" (shelf)

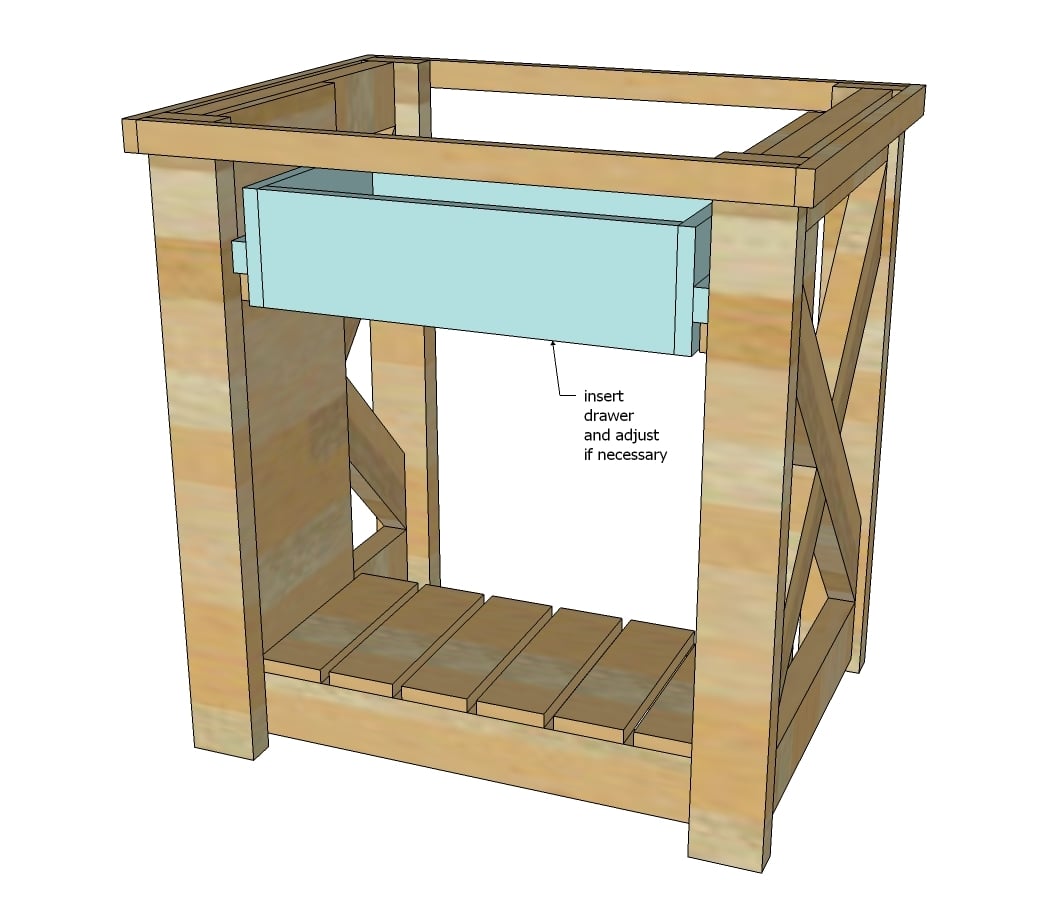

DRAWER

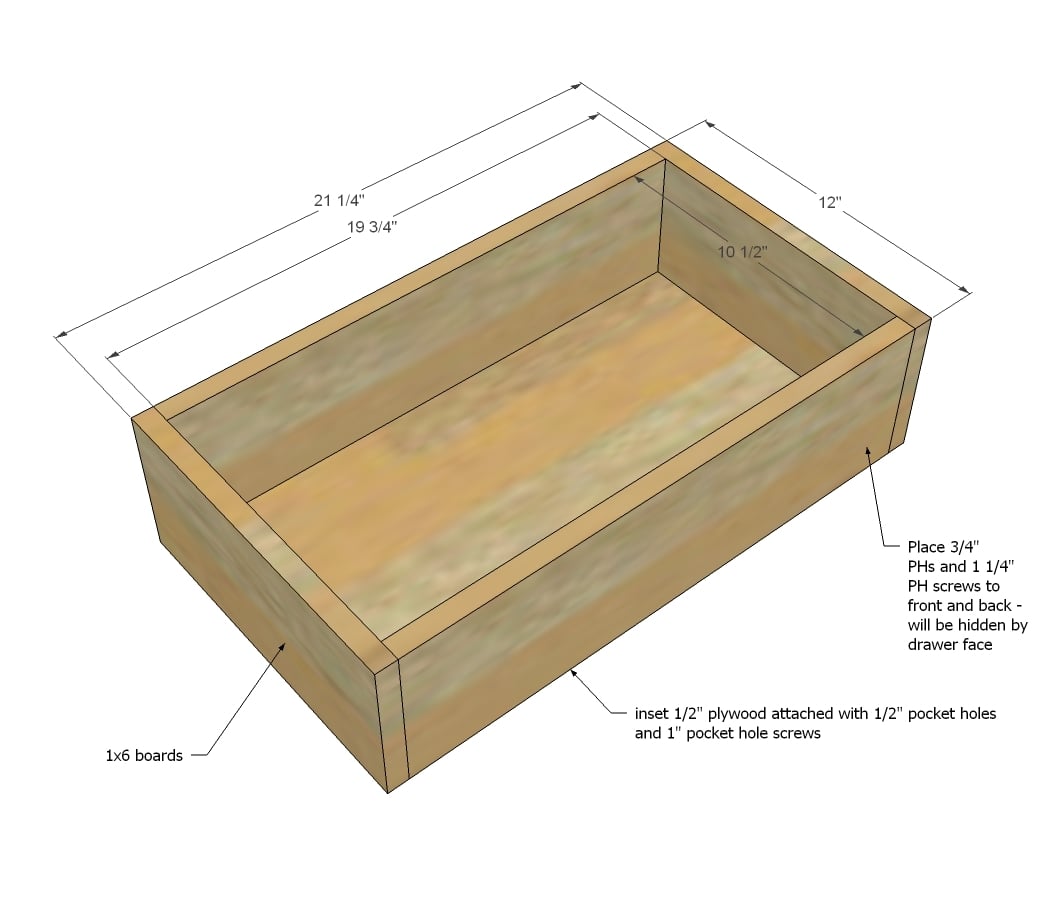

2 - 1x6 @ 19 3/4"

2 - 1x6 @ 12"

1 - 1/2" plywood @ 19 3/4" x 10 1/2"

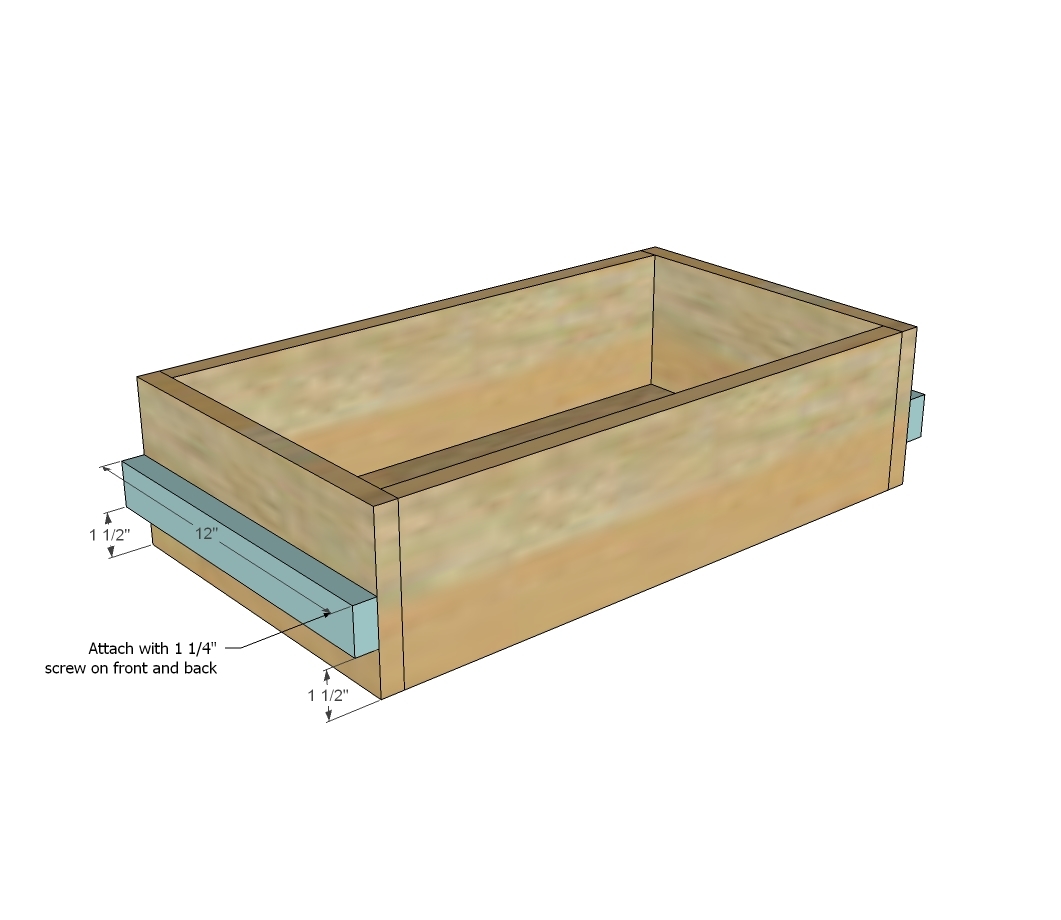

2 - 1x2 @ 12"

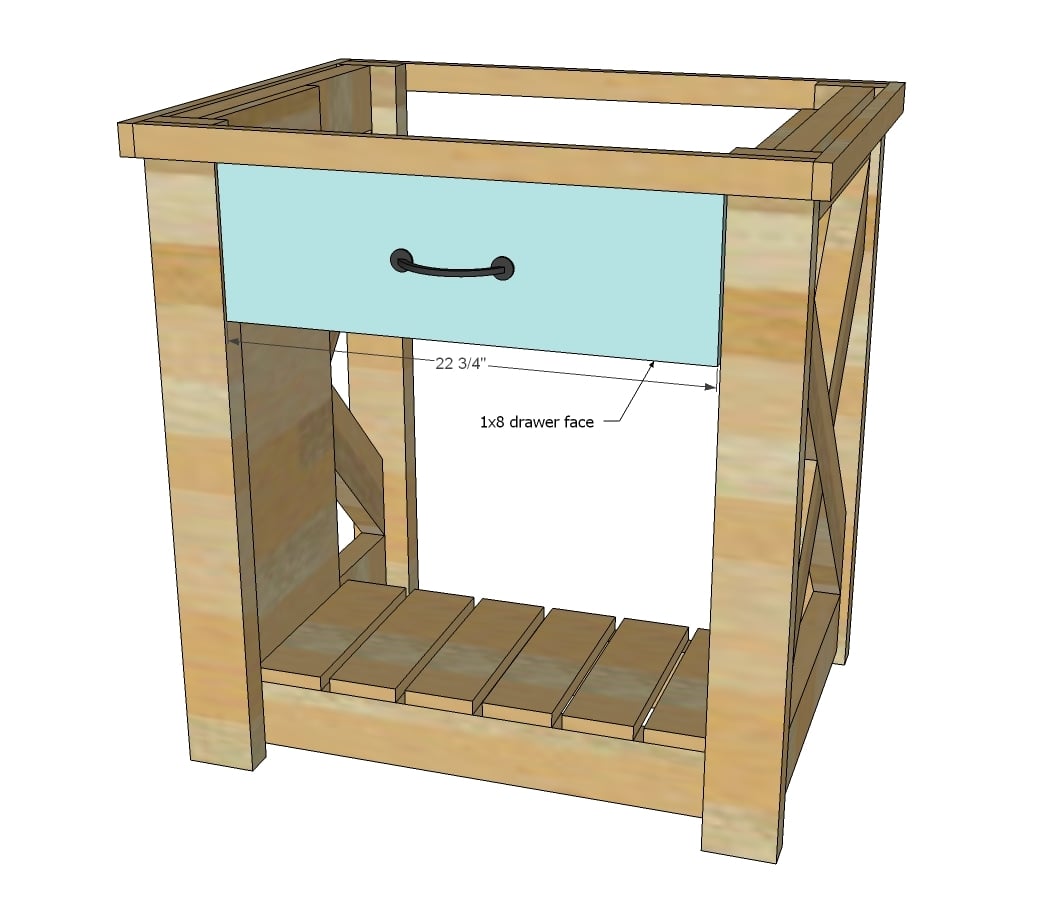

1 - 1x8 @ 22 3/4"

TOP

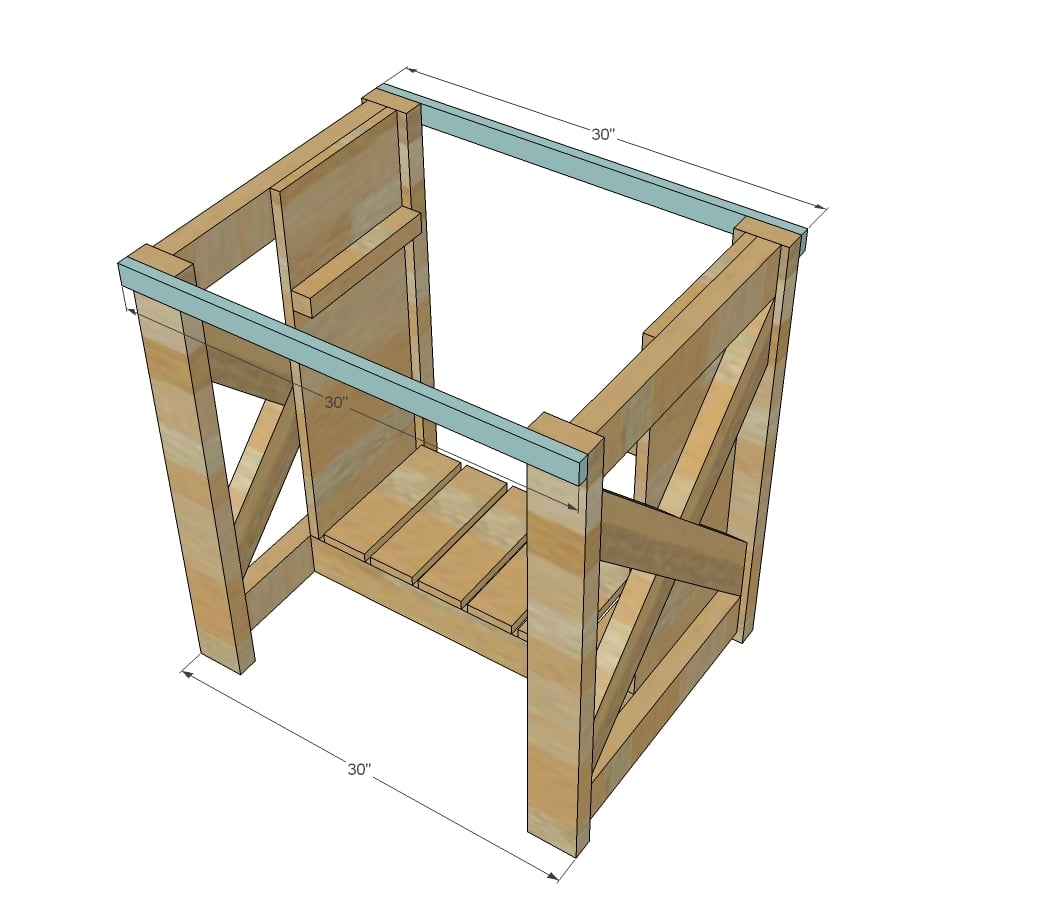

2 - 1x2 @ 30"

2 - 1x2 @ 24"

1 - project panel 24" wide x 31 1/2" long

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 2

Step 3

Step 4

Step 6

Step 10

Step 11

Step 13

Step 14

Step 15

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

JoanneS

Sat, 08/31/2013 - 10:02

Beautiful Island!

This island is so beautiful! Love the finish and the hooks, and the drawers that slide on wood cleats. (ps - the kitchen in the background is stunning!)

cassiet717

Sun, 09/01/2013 - 10:24

Finish!

I'm in love with the rustic finish. You see a lot of the "Pottery Barn" distressed paint these days (which I also love), and this is such a nice, fresh take!!

paul_spiller

Tue, 09/02/2014 - 04:37

caster wheels

Hi,

Love the project. Put it together in a weekend and then took 3 weeks to stain and finish ( clearly I don't enjoy that bit as much as the construction).

I am almost complete for the project and am really pleased how it has turned out. The last step is to fix some casters. I went down to Lowes looking and i didn't see any plate casters that would fit on the end of a 2x4 piece of wood. Does anyone have any advice / ideas which ones are best? A link would be lovely ;-)

dbizzle

Tue, 09/02/2014 - 09:29

Casters

I know the place doesn't have the best reputation, but I buy almost all of my casters at harbor freight.

For 2x4 legs, you might be better off drilling up into the leg, adding a t-nut, and using screw-in casters.

paul_spiller

Wed, 09/03/2014 - 15:25

adding a T-Nut

dbizzle,

That is an awesome idea. I thought of that but didn't know what it was called. T-Nut!!!!

Lowes has screw in casters for sure so that would be perfect if i can one with an internal thread of the same size.

Thanks

Paul

steinfal

Sat, 10/04/2014 - 07:36

Two modifications

Hey, I love this plan. I did however make two modifications to the drawer. One keeps it from closing too far and the other keeps it from falling down when you pull it out. Check out the mods here, hope you enjoy...

http://www.prolificoaktree.com/2-uncategorised/10-improvements-to-rustic-x-small-rolling-kitchen-island

rwshoaf

Sat, 06/29/2019 - 15:30

plans

Trying to pring

rwshoaf

Sat, 06/29/2019 - 15:30

Still cannot print.

Still cannot print.

zannej

Sat, 11/19/2022 - 06:46

Ideas for modifications

I love this idea. My friend has a small kitchen and doesn't have room for a stationary island or a large island but this would be great for his kitchen-- especially since he loves the rustic look and the X on the sides. I did want to have some modifications though. First off, I would cut the legs by 1/2" (down to 32"H) and have a sort of butcherblock top comprised of 2x2 furring strips. The long part of the X would then be 27-1/4 long. The short pieces would be 13-5/8" long.

I want to have the drawer use ball bearing full-extension glides so I'm thinking some 10" glides (having a hard time finding 11" ones) would work. The drawer could be wider that way. The glides I looked at were 1/2" thick and ~1-3/4" high. I wanted the panels behind the X to extend all the way instead of only about halfway. I found that the only 1/2" plywood I can find affordably in my area is only 2'x2' and will fit just about right. I wanted a solid bottom shelf instead of one with gaps. I also wanted a shelf on the opposite side behind the drawer. The drawer's outer length would still be 12" but the width would be around 22". I may eliminate the trim piece below the drawer to allow taller things to be placed underneath.

I'd paint the main thing gray (to match the cabinets but the inside panels under the X would be gloss black). In order to get the drawer slides to fit I'm thinking of getting some 2x4s and notching them to go around he panels. I'm still trying to figure out the full lumber list. We are thinking of using some pallet wood if we can find it. Or some old studs from a wall we are taking out.

I'm trying to figure out how to add pictures from Sketchup but its not working.