Create your own beautiful, customizeable and functional rolling bar cart. Free step by step plans with diagrams and shopping list and cut list by Ana-White.com

Collections

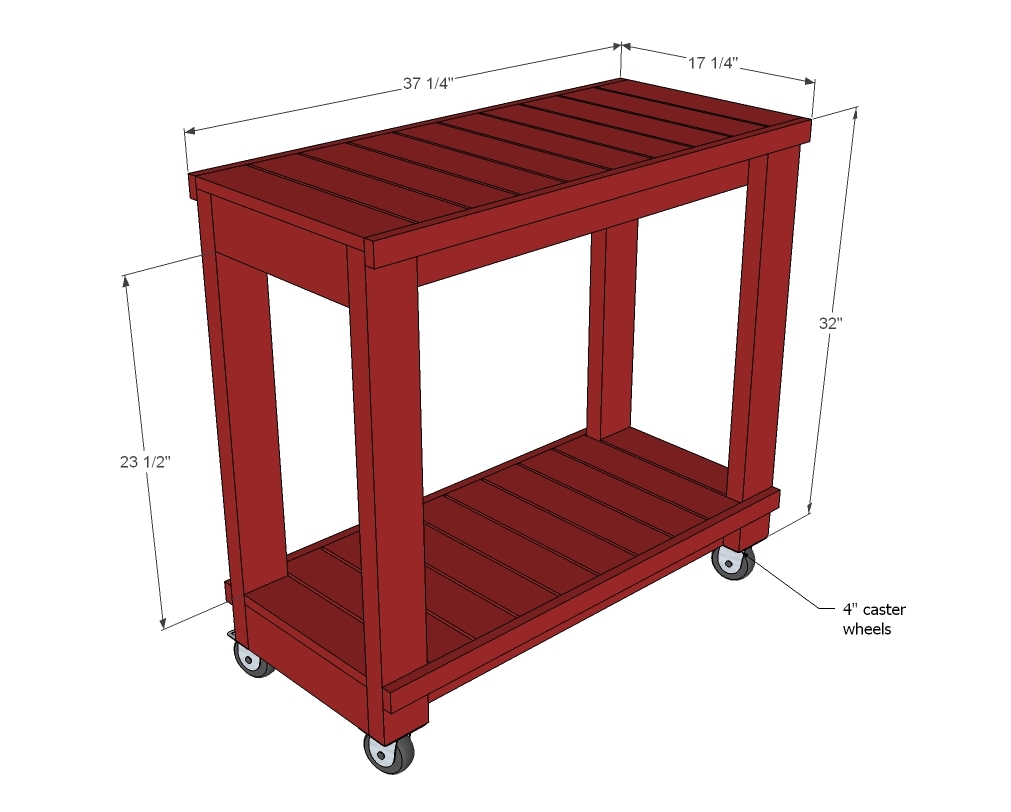

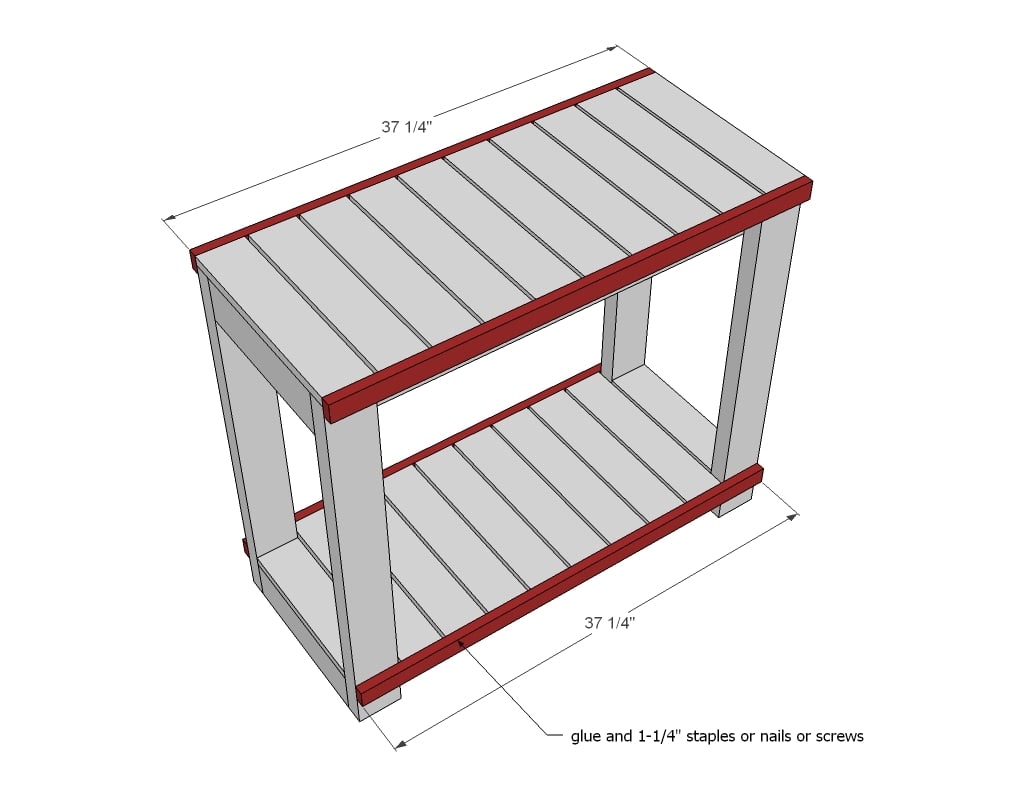

Dimensions

Dimensions shown above

Preparation

Shopping List

4 - 2 x 4 x 8'

3 - 1 x 4 x 10'

2 - 1 x 2 x 8'

2-1/2" self tapping exterior screws

1-1/4" galvanized staples or screws (for attaching slats)

glue

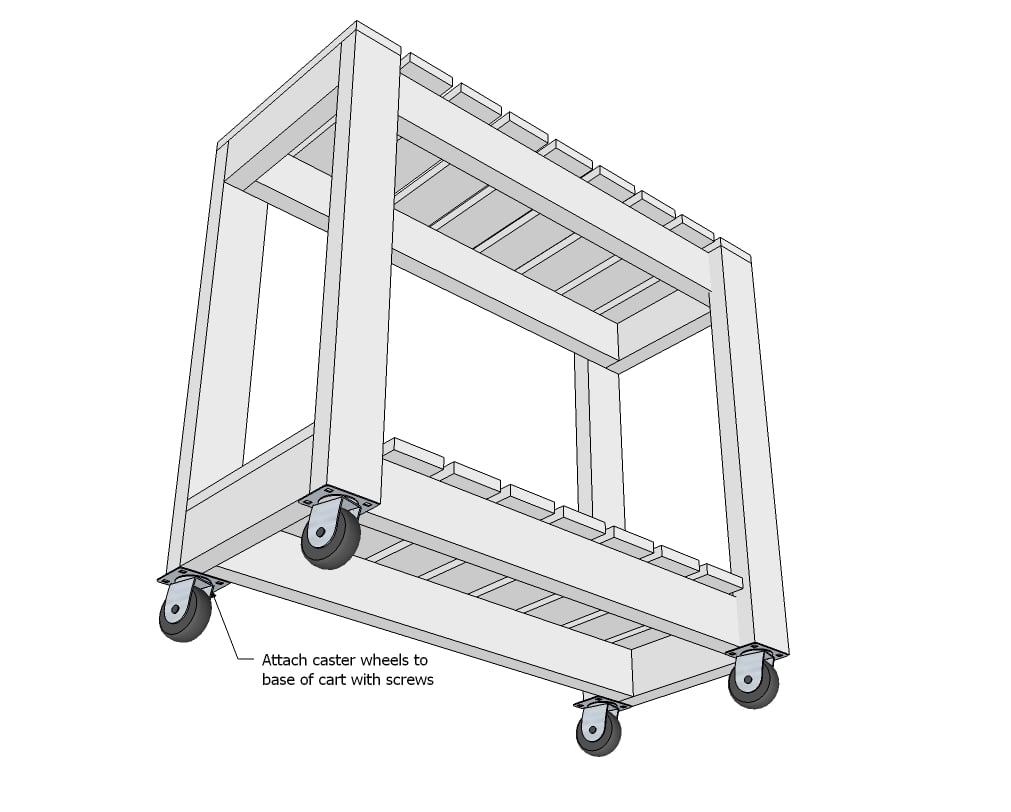

4 - 4" caster wheels

towel bar or pipe fitting for towel bar

glue, paint and primer

Common Materials

Cut List

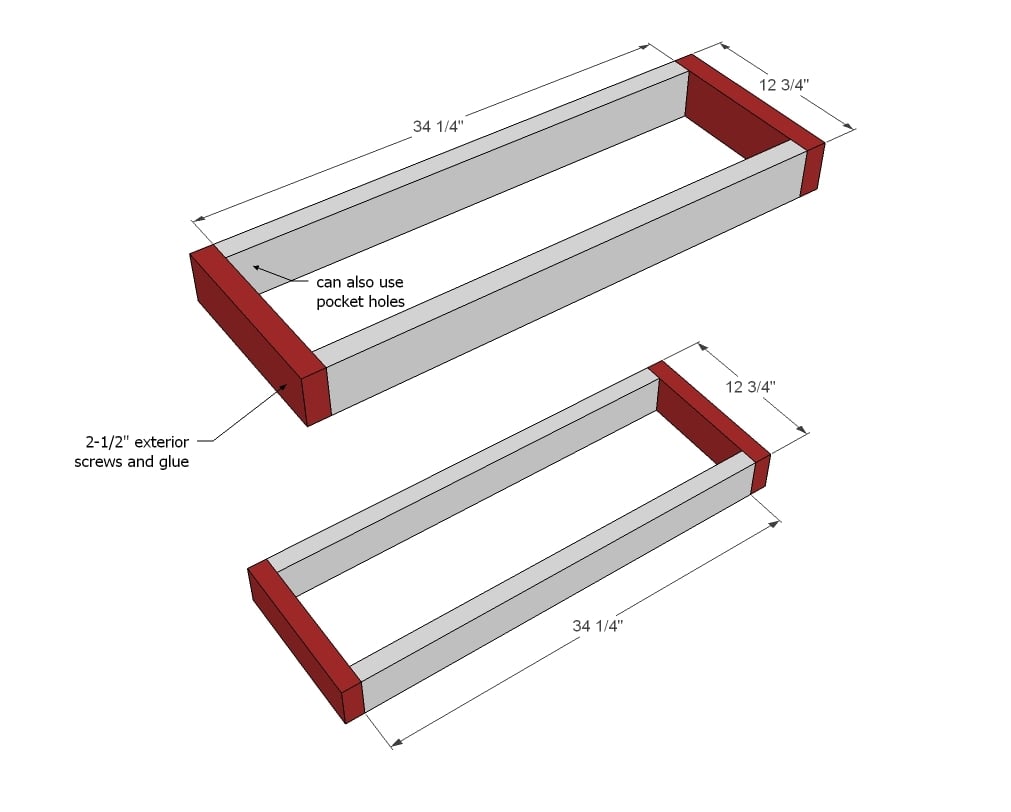

4 - 2 x 4 @ 12-3/4" - End Aprons

4 - 2 x 4 @ 34-1/4" - Side Aprons

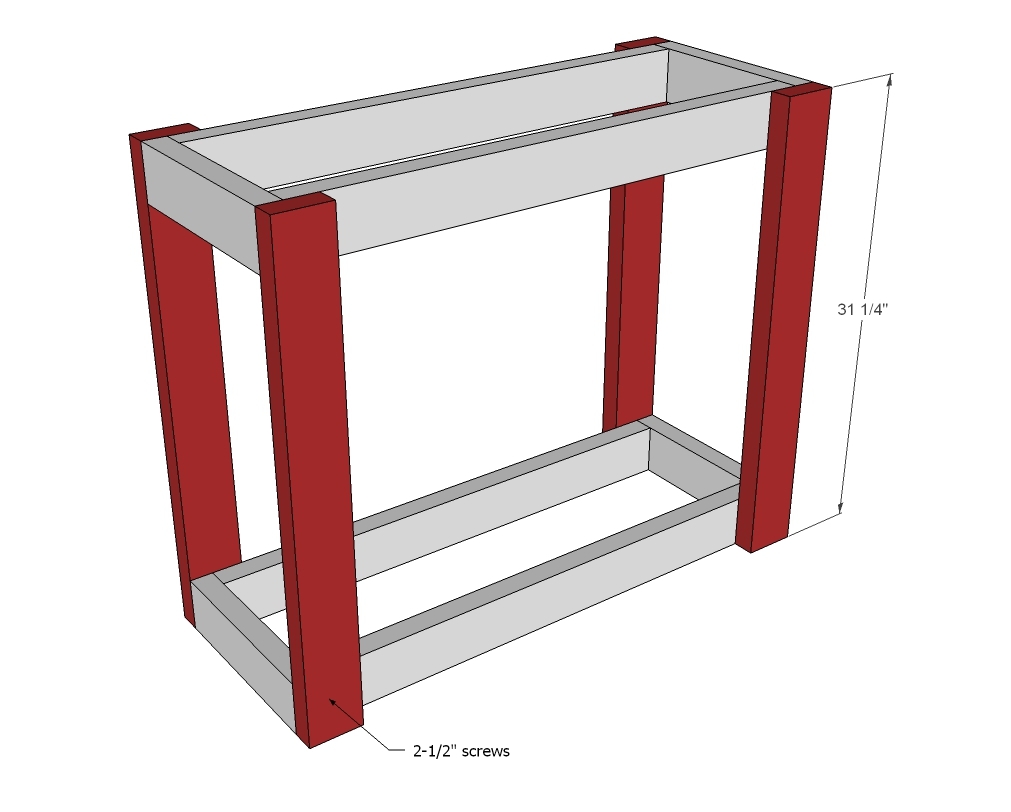

4 - 2 x 4 @ 31-1/4" - Legs

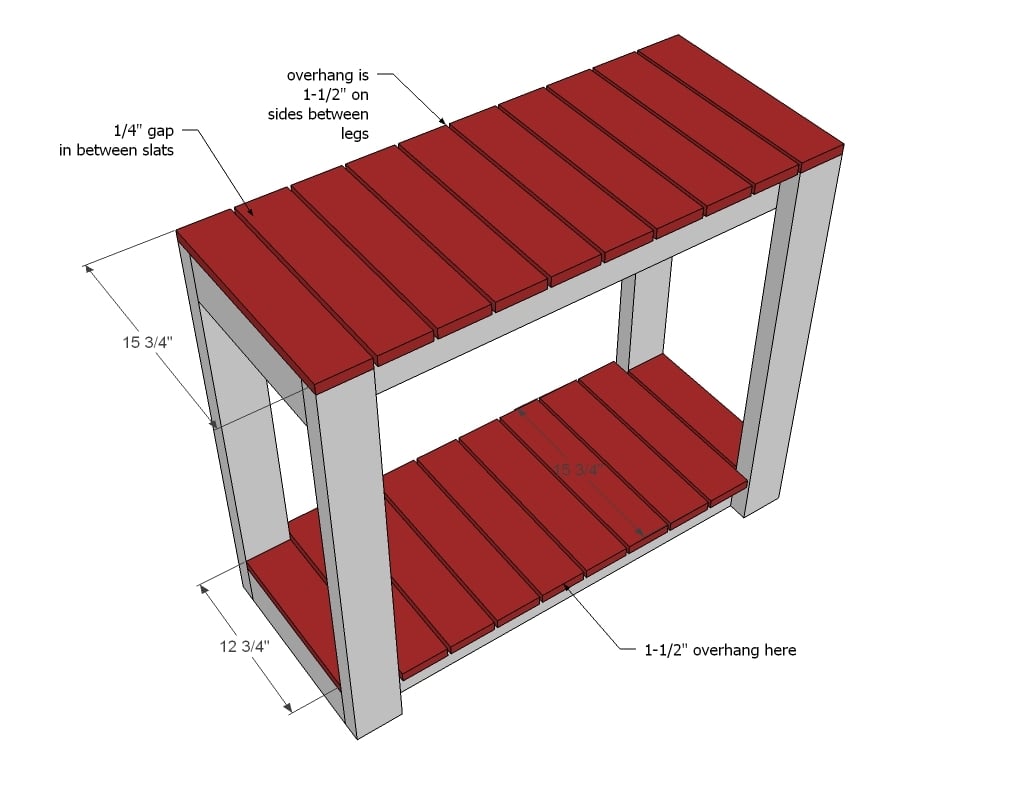

2 - 1 x 4 @ 12-3/4" - Shorter bottom shelf slats

18 - 1 x 4 @ 15-3/4" - Top and bottom shelf slats

4 - 1x2 @ 37-1/4" - End Trim

Instructions

Project Type

Comments

kmatt55

Sun, 08/31/2014 - 20:13

Casters size

Your photos say those are 4 inch casters but I can clearly see they are not, especially measured against the 2x4's for the base. What size are they? Thanks!

rajasaab

Fri, 04/17/2020 - 05:20

Towel Bar - Pipe Length?

Awesome design! what was the Length of the Pipe piece that you used for the towel hanger

Angel

Sun, 06/28/2020 - 07:31

I use a 10 inch pipe. I…

I use a 10 inch pipe. I bought a 12 and it was to big.