The best workbench you can build! This workbench features a miter saw stand, with roll away carts to hold all your tools and create work spaces. It's easy to customize, and the best part, it all rolls away when done!

Free step by step plans from Ana-White.com

Pin For Later!

Preparation

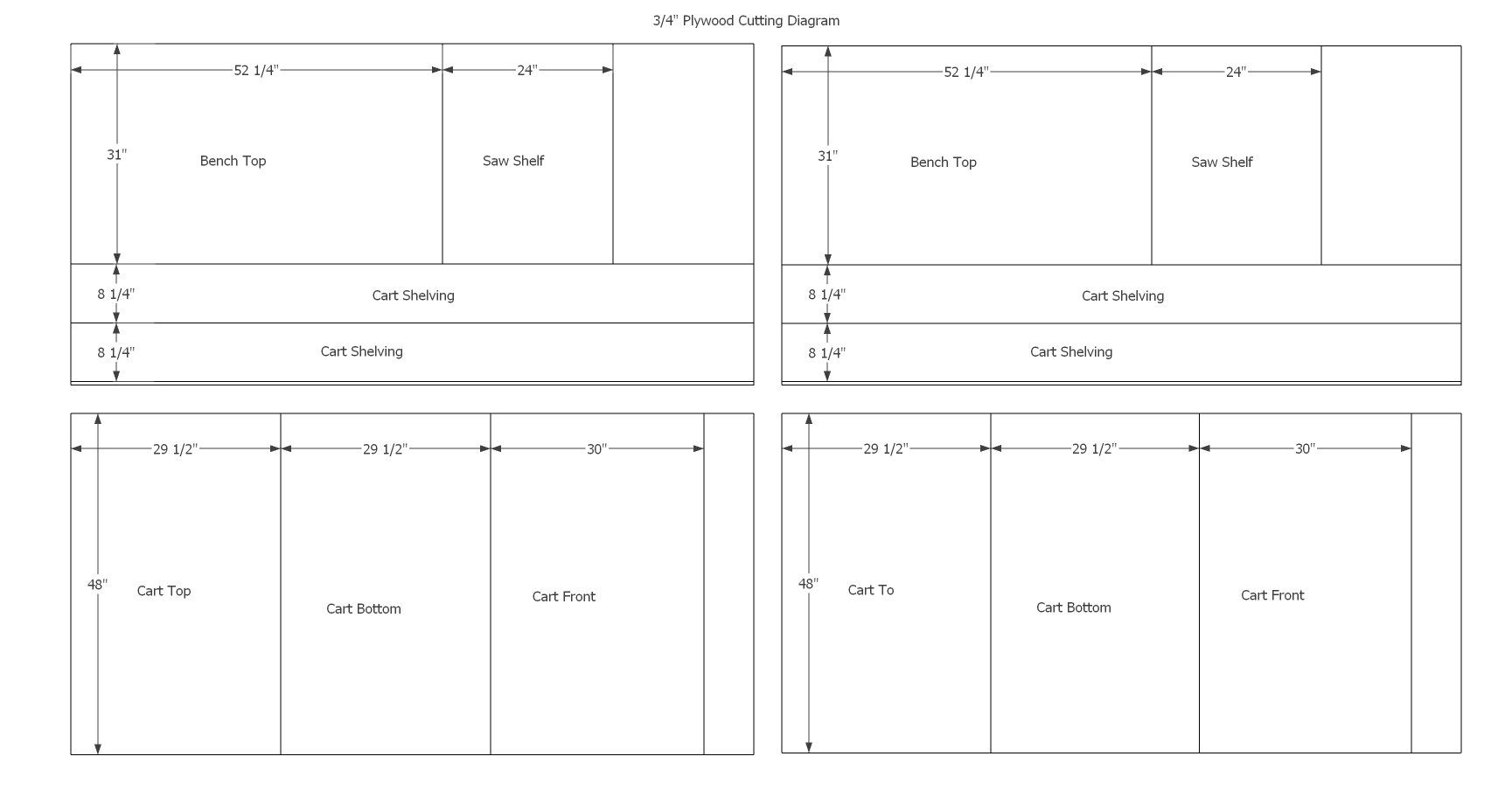

• 4 Sheets of 3/4” plywood

• 2 sheets of 1/4" plywood

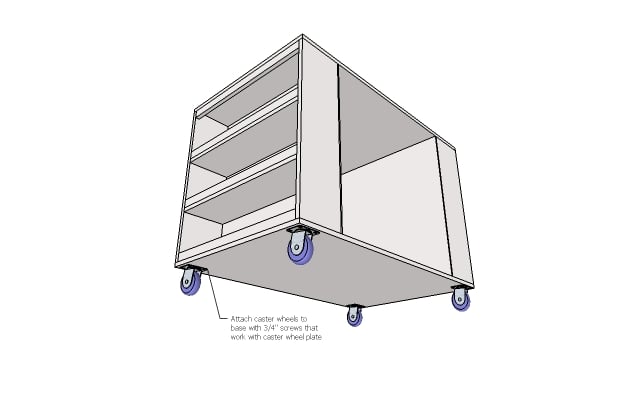

• 8 – 3” casters with brakes

• 3/4” screws for attaching caster wheels

• 11 – 2x4 @ 8 feet long

• 8 – 1x2 @ 8 feet long

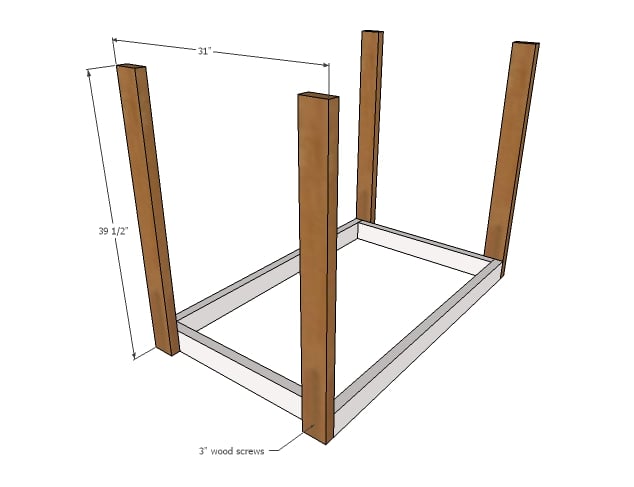

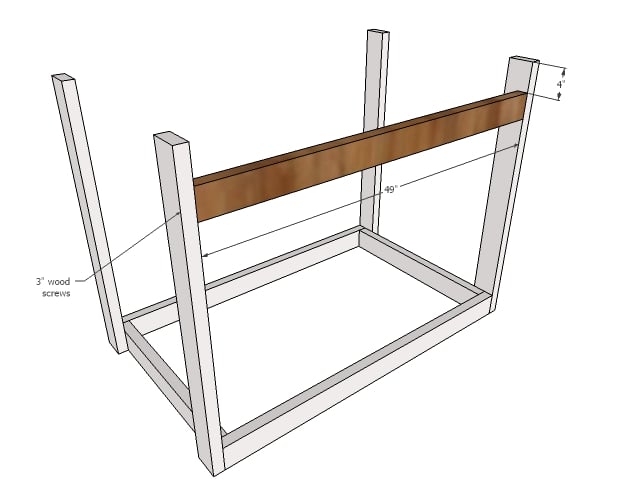

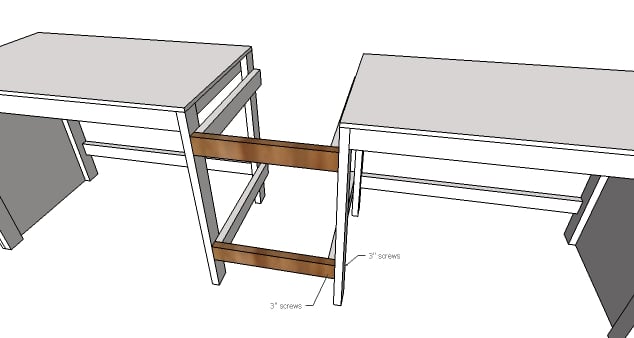

• 3” self tapping wood screws

• 2” and 1-1/4” 18 gauge staples

• 4 handles for carts

Workbench Cut List

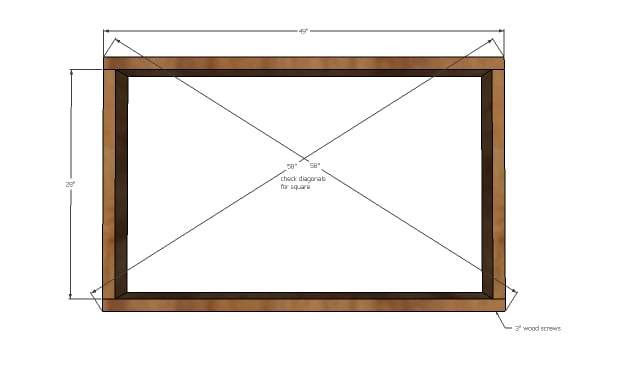

• 6 – 2x4 @ 49”

• 4 – 2x4 @ 28”

• 8 – 2x4 @ 39-1/2”

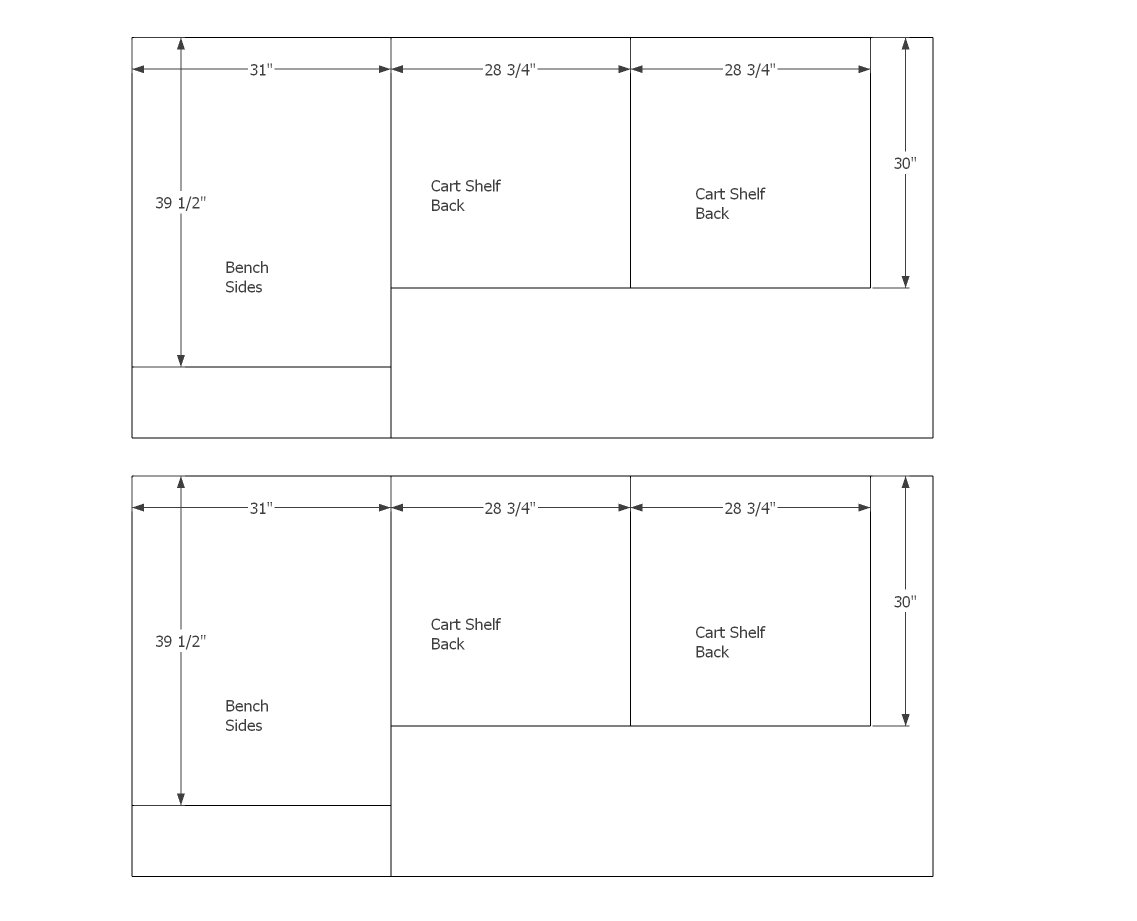

• 2 – 1/4” plywood @ 39-1/2” x 31” (see plywood cutting diagrams)

• 2 – 3/4” plywood @ 52-1/4” x 31” (see plywood cutting diagrams)

• 4 – 2x4 @ 29-1/2”

• 2 – 2x4 @ width of saw (shown at 24”)

• 2 – 3/4” plywood @ width of saw x 31” (shown at 24”)

Cart Cut List

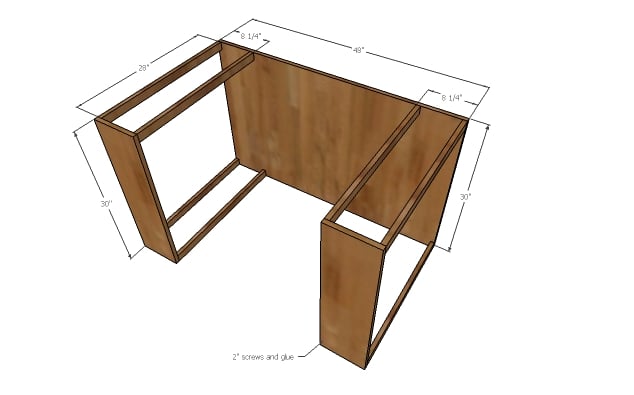

• 2 –3/4” plywood @ 48” x 30” (see plywood cutting diagrams)

• 4 – 3/4” plywood @ 8-1/4” x 30” (cut from scraps, see plywood cutting diagrams)

• 24 – 1x2 @ 28”

• 8 – 3/4” plywood @ 8-1/4” x 28” (cut from scraps, see plywood cutting diagrams)

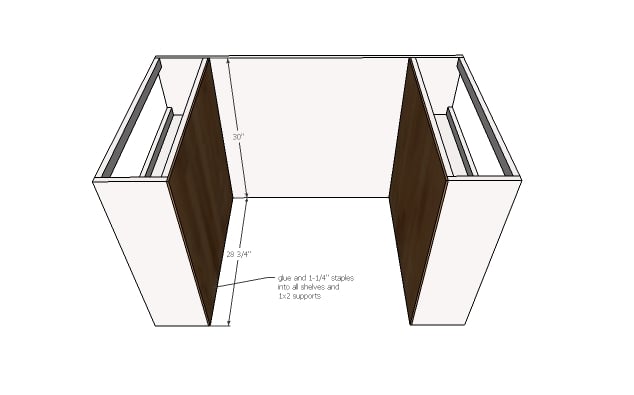

• 4 – 1/4” plywood @ 30” x 28-3/4”

• 4 – 3/4” plywood @ 48” x 29-1/2” (see plywood cutting diagrams)

Suggested Plywood Layouts for the Cuts

Instructions

Step 1

Step 2

Step 3

Step 4

Step 6

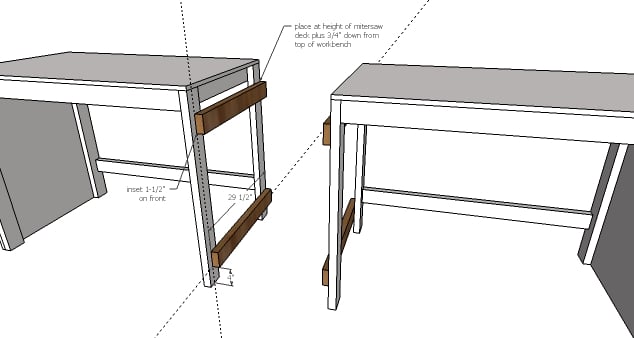

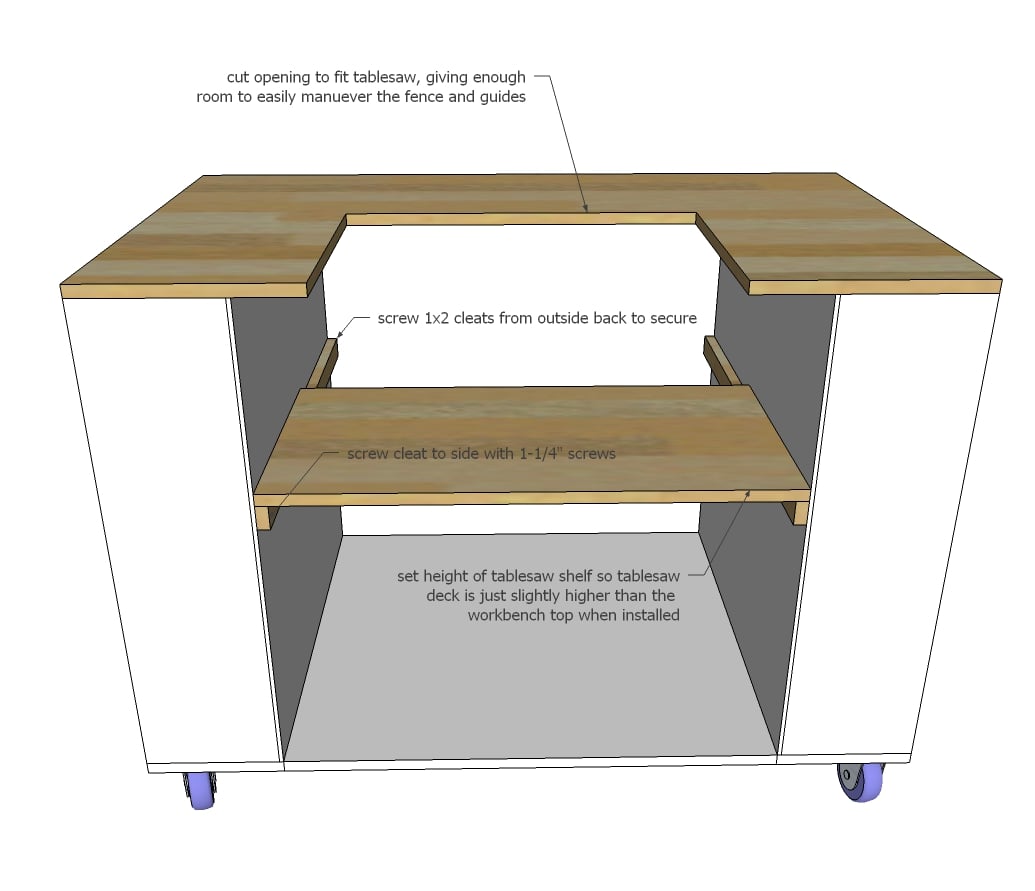

Miter Saw Shelf Step 1: Cleats

Measure the height of your miter saw deck. Add 3/4” to this measurement. Attach top cleats to sides of workbenches this measurement down from top of workbench. Cleats are flush to back, 1-1/2” less on front side. Use 3” screws.

Attach bottom shelf cleats with 4” space underneath.

Step 7

Step 8

Step 9

Cart Step 1: Caster Wheel Height

Measure the overall height of your caster wheels. Maximum clearance under workbench is 36” but some space should be left to allow cart to slide in. Cut list as shown is for casters with 3-3/4” clearance – adjust your cuts if your caster wheels are different heights.

Also double check the final location of your workbench for sloping garage floors and give extra room if in doubt.

Step 10

Step 11

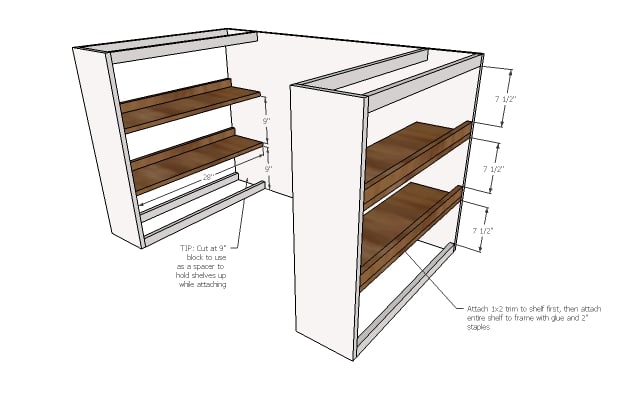

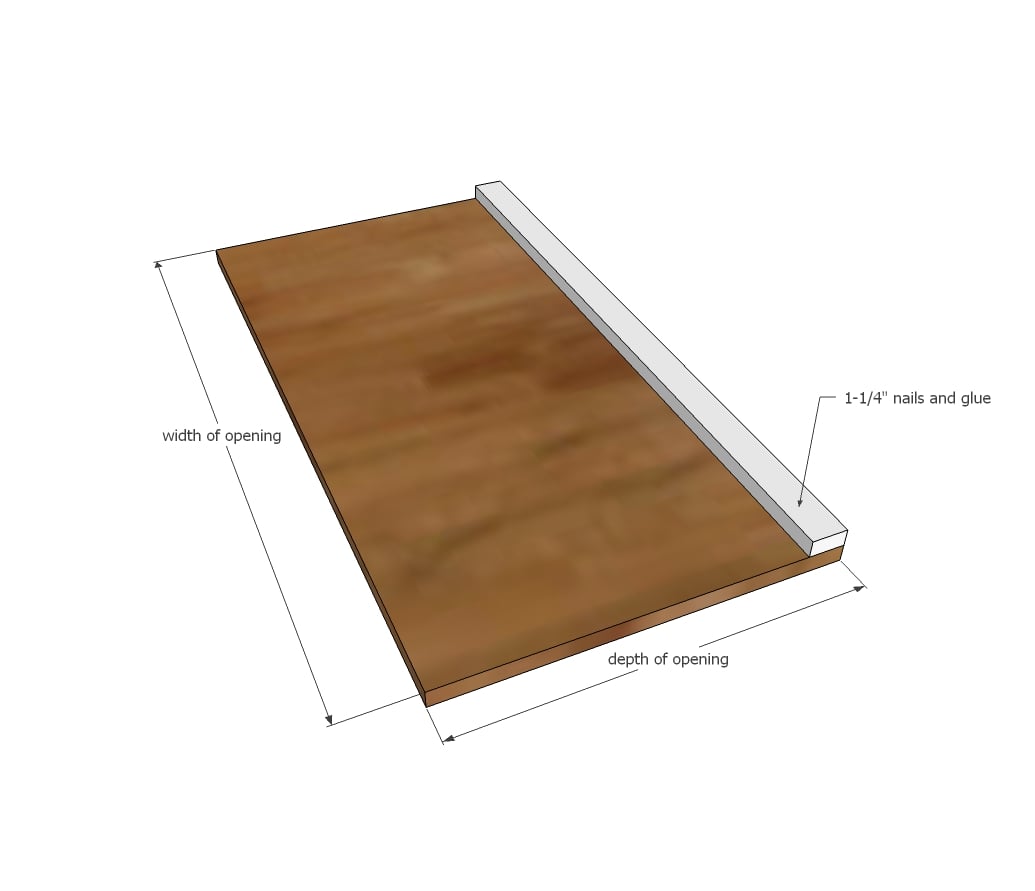

Cart Step 3: Shelves

Attach remaining 1x2s to shelves with 1-1/4” staples from underside. Then attach shelves inside cart frames with 2” screws or staples and glue.

TIP: Cut two 9” blocks of wood and use as spacers when placing shelves.

NOTE: Shelves can be placed at any height – customize to fit your needs and toolset.

Step 15

Step 16

Step 17

Step 18

Step 19

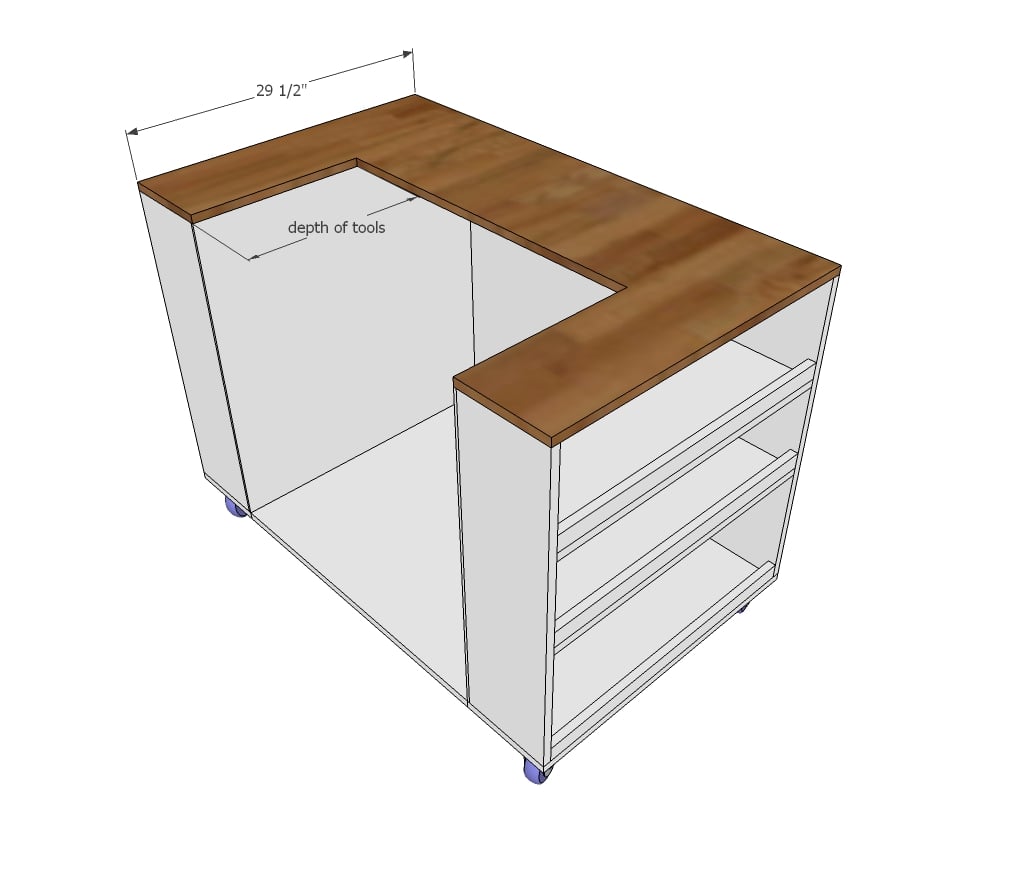

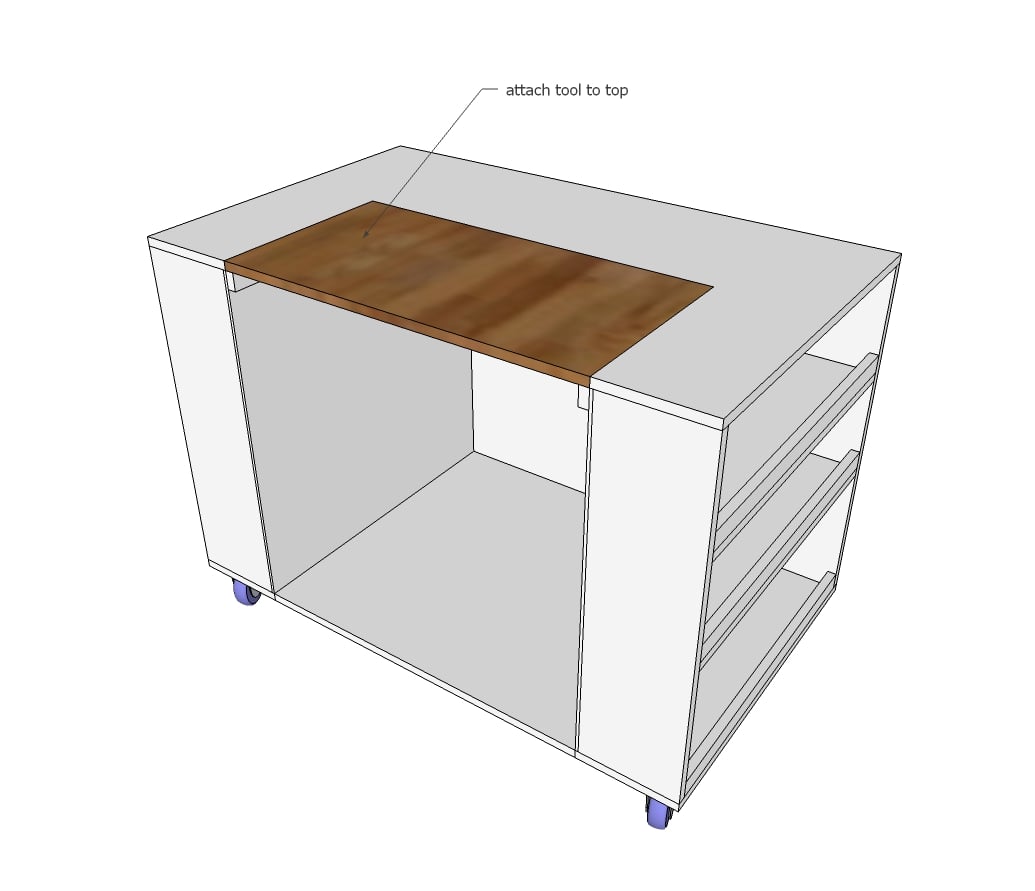

Step 5: Tablesaw Modification

Repeat steps as directed for benchtop tools, except custom cut tabletop out to fit your tablesaw, leaving enough room for the tablesaw fence, guides and accessories to freely move. Use cleats and ¾” plywood to create a shelf for the tablesaw. When installation is complete, the tablesaw deck should be slightly higher than the tabletop itself. Secure tabletop to shelf.

Comments

boettg33

Thu, 12/30/2021 - 07:16

Great use of space.

With a small one car garage shop, space is a premium. I picked up plans for a rolling miter stand with fold up wings on each side. Giving the total length of 96". That said I stumbled across this build, and wow I am impressed. I've seen other plans integrating the miter saw into cabinets on one side and a set of drawers on the other. Yet I didn't feel that solution met my space constraints and overall functionality. You have a stationary stand for the miter saw, but go further in the functionality by adding the two rolling carts. This effectively uses the space more efficiently allowing for other pieces in my shop to be consolidated. One thing I don't understand is why you don't sell your plans.

joda

Thu, 01/05/2023 - 14:28

Table Saw/Dust Collector

Curious what folks do with dust collection options when using one of the carts as a table saw. Debating whether I just make a hole on the front of the cart to allow for a shop vac/dust collector?