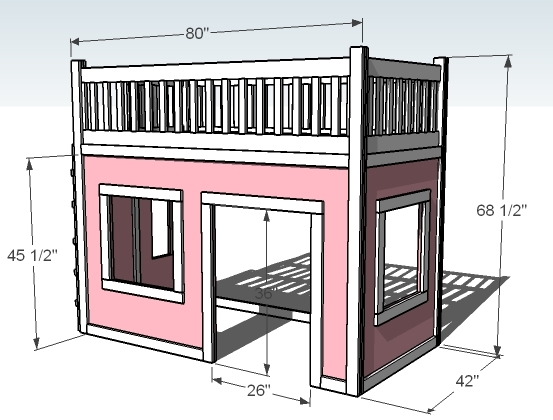

Building a playhouse bed is easier than you think with this straight forward plan. It's a big project, it's going to take patience and persevering, but as so many of our readers have discovered, well worth the hard work! Special thanks to Kimberly for sharing her amazing photos of Princess Katherine's bed.

Preparation

2 sheets of 3/4″ MDF, particle board or plywood (sanded to reduce splinters)

7 – 1x2s, 8′ long

15 – 1x3s, 8′ long (not including 1x3s for mattress slats)

6 – 1x4s, 8′ long

3 – 2×2, 8′ long

1 1/4″ pocket hole screws

2″ self tapping wood screws

1 1/4″ brad nails

2″ brad nails

wood glue

wood filler

Finishing Supplies

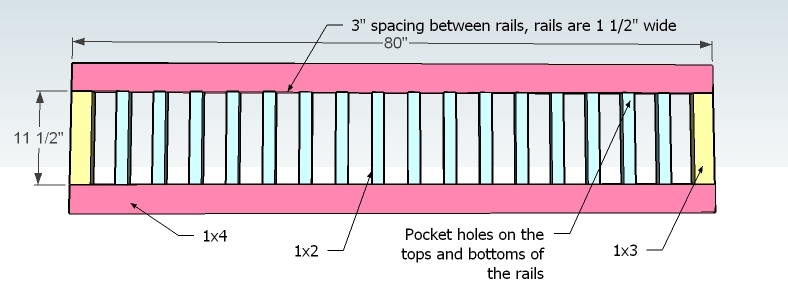

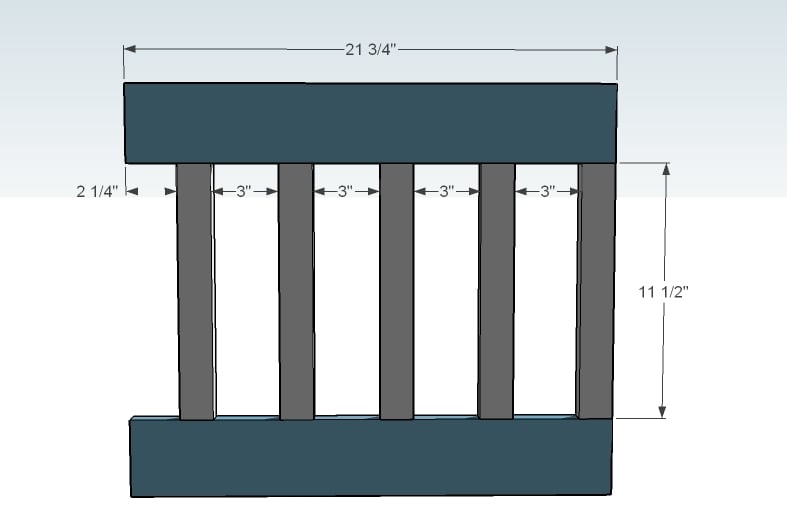

53 – 1×2 @ 11 1/2″ (Rails)

4 – 1×4 @ 80″ (Top and Bottoms of Rails)

4 – 1×3 @ 11 1/2″ (End of Rails – Front and Back rails)

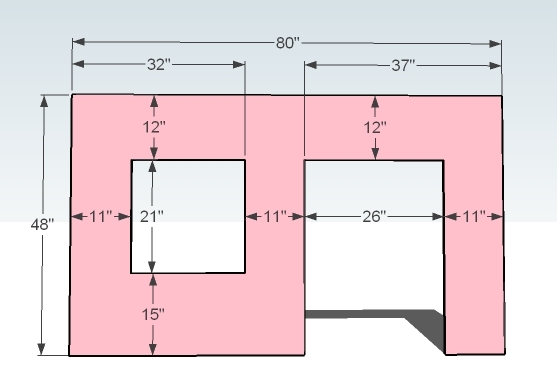

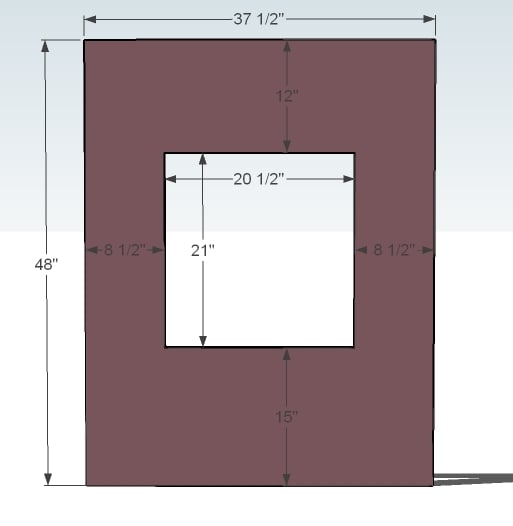

1 – 3/4″ Plywood or MDF @ 48″ x 80″ (Front Plywood)

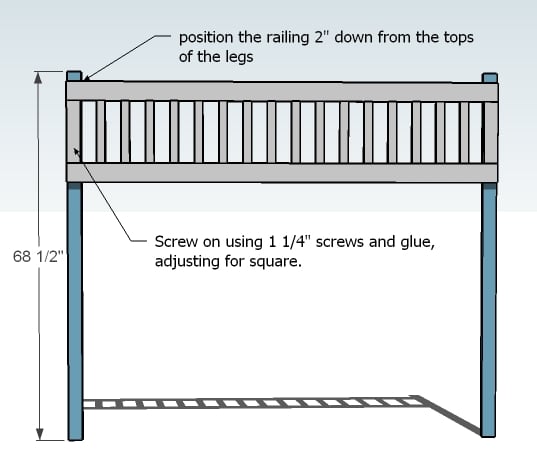

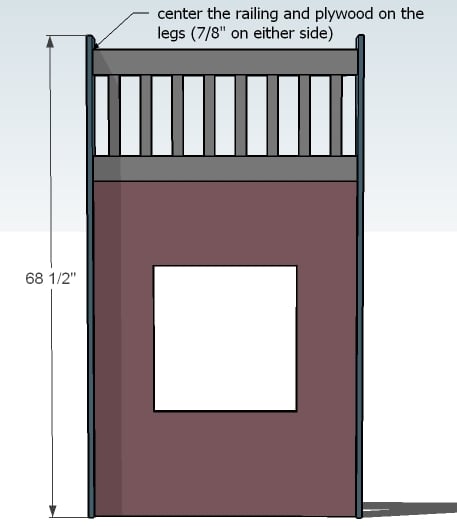

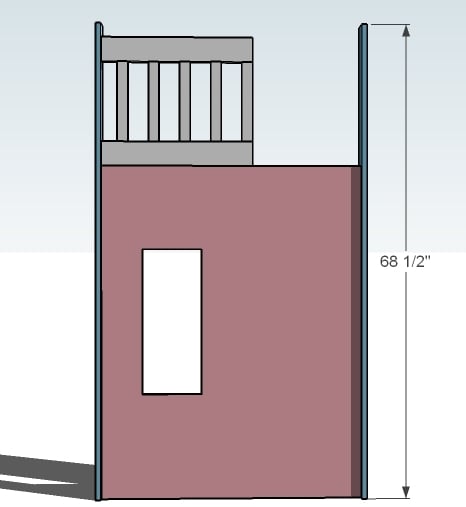

8 – 1×3 @ 68 1/2″ (Legs)

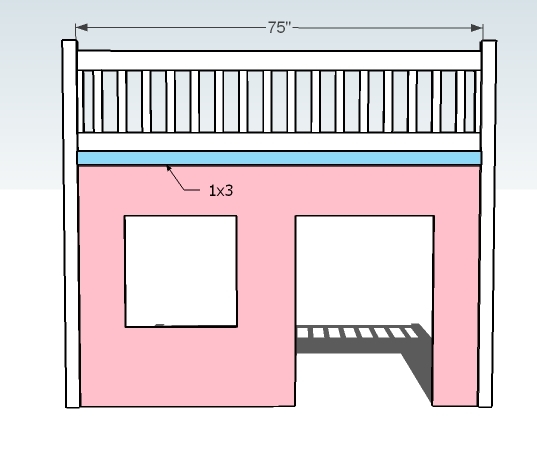

1 – 1×3 @ 75″ (Top Front Trim)

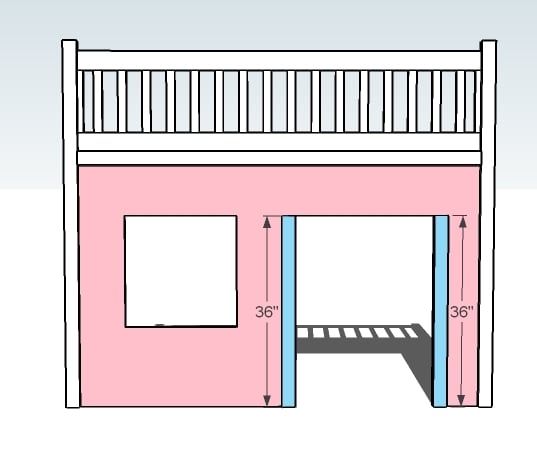

2 – 1×3 @ 36″ (Door Trim)

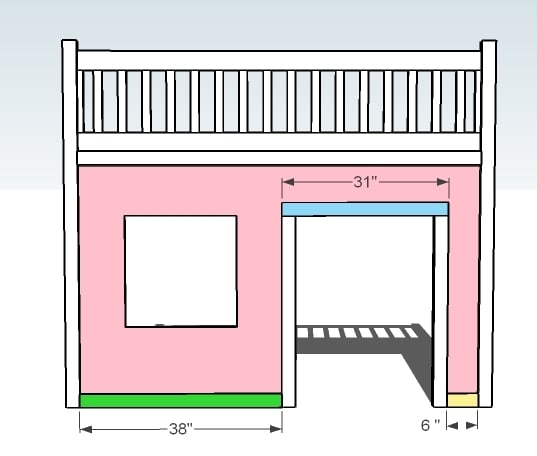

1 – 1×3 @ 31″ (Door Trim)

1 – 1×3 @ 38″ (Front Trim)

1 – 1×3 @ 6″ (Front Trim)

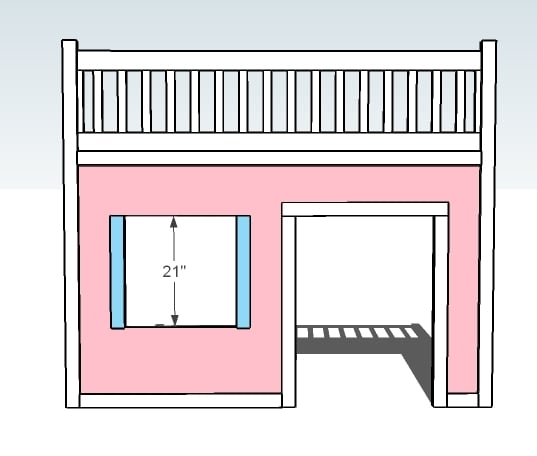

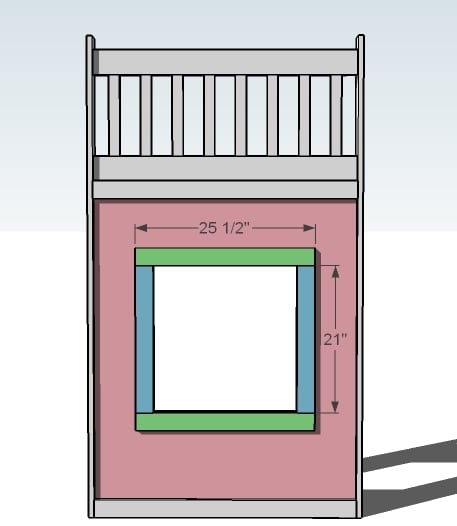

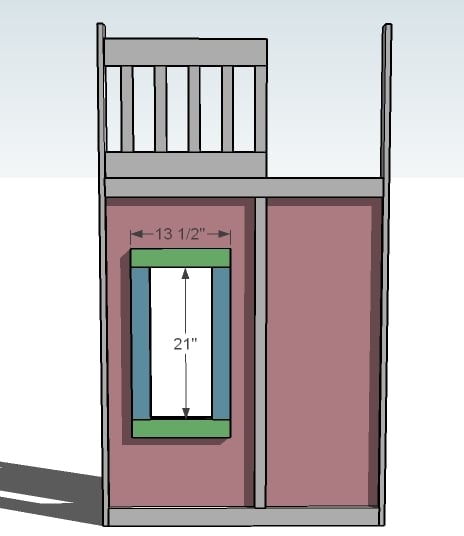

6 – 1×3 @ 21″ (Window Trim)

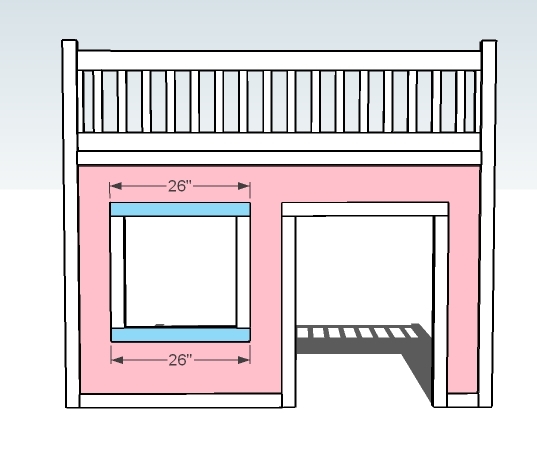

2 – 1×3 @ 26″ (Window Trim)

4 – 1×3 @ 2″ (Top Leg Filler Pieces)

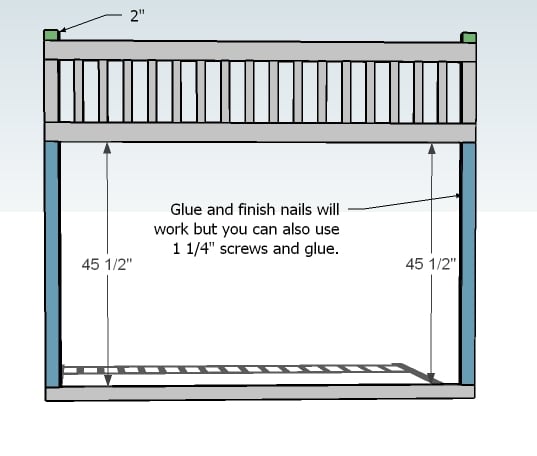

2 – 1×3 @ 45 1/2″ (Back Leg Filler Pieces)

1 – 1×3 @ 80″ (Back Base Trim)

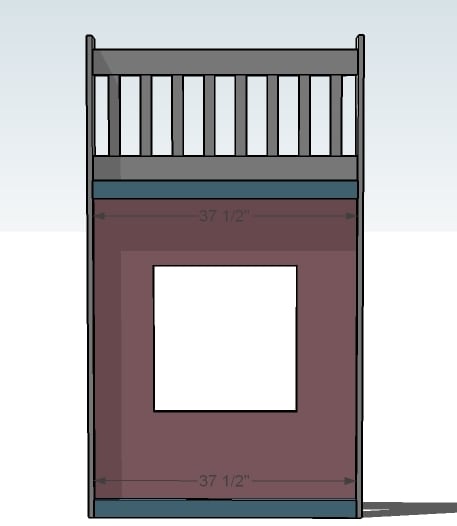

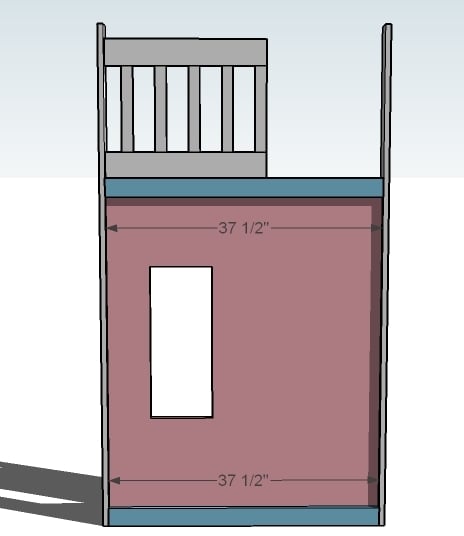

2 – 1×4 @ 37 1/2″ (Top and Bottom of Side Rail)

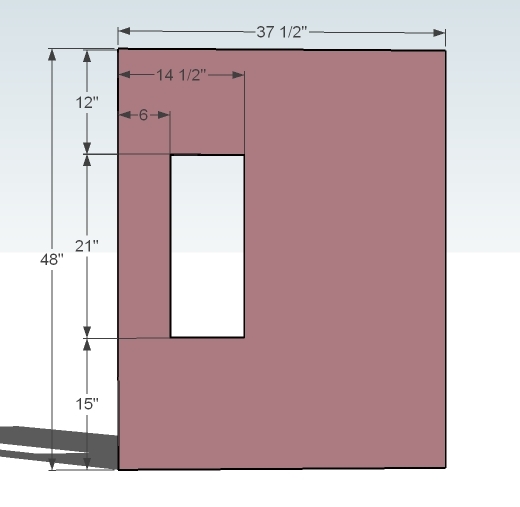

2 – 3/4″ Plywood @ 48″ x 37 1/2″ (Side Plywood)

4 – 1×3 @ 37 1/2″ (End Trim)

2 – 1×3 @ 25 1/2″ (Window Trim)

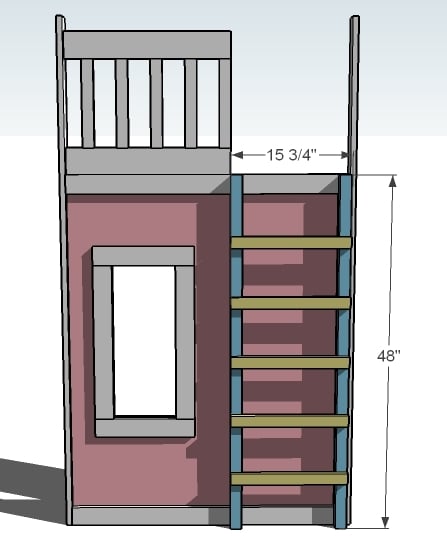

2 – 1×4 @ 21 3/4″ (Ladder End Rail Top and Bottom)

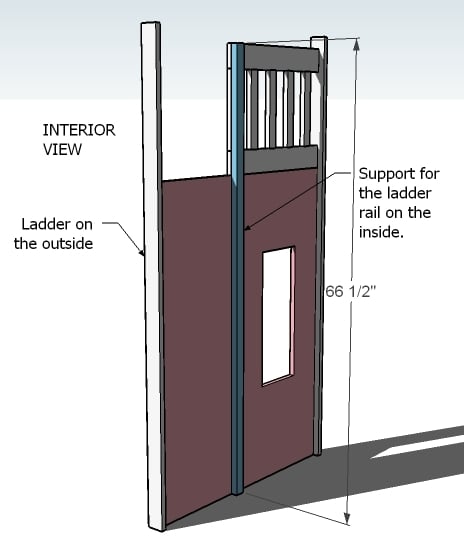

1 – 1×2 @ 66 1/2″ (Ladder Inside Support)

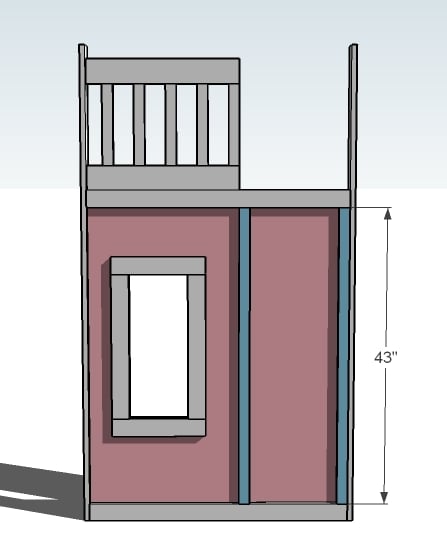

2 – 1×2 @ 43″ (Ladder Spacer)

2 – 2×2 @ 48″ (Ladder Sides)

5 – 1×2 @ 15 3/4″ (Ladder Rungs)

2 – 1×3 @ 13 1/2″ (Ladder Side Window Trim)

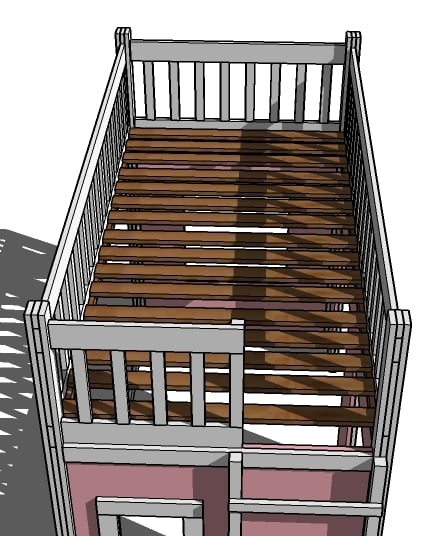

2 – 2×2 @ 75″ (Cleats for the mattress support frame)

1x3s @ 39″ (Mattress Slats, as recommended by the mattress company)

Instructions

Step 1

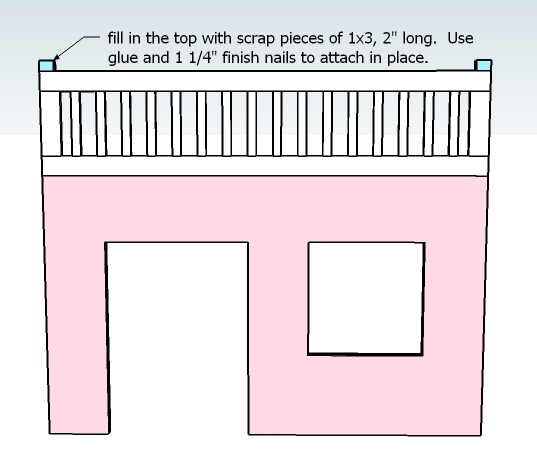

Front and Back Railing

Build two of these – one for the front, and one for the back. Simply drill two pocket holes on both ends of all of the rails (blue) and ends (yellow). Mark the top and bottoms (pink) with 3″ spaces, remembering that a 1×3 is actually 2 1/2″ wide and a 1×2 is actually 1 1/4″ wide. Use glue and 1 1/4″ pocket hole screws to attach the rails to the tops and bottoms, as shown above. Set aside.

Step 2

Step 3

Step 4

Step 7

Step 8

Window Trim

Trim out the window as shown above. You can alternately build your window frame with a Kreg Jig™, and then attach to the plywood front.

Step 9

Step 10

Step 12

Step 13

Build the Side Railing

Step 14

Step 15

Step 16

Window Trim

The best way to go on window frames is to build them separately with 1 1/4″ pocket hole screws, and then tap on with finish nails and glue. You can alternately attach with 1 1/4″ finish nails and glue.

This completes the end wall without the ladder. Click on NEXT PAGE below to see how to build the ladder end.

Step 18

Step 19

Step 20

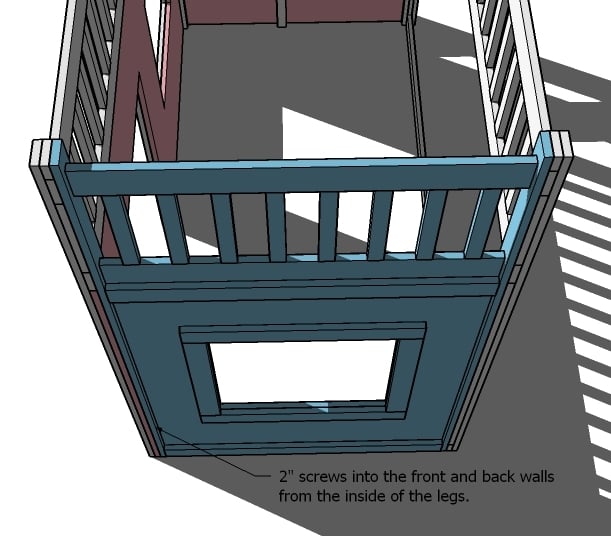

Ladder Railing Support

So I tossed and turned on this one, knowing that little hands are going to be pulling on the top of this railing and knowing it needed to be sturdy. The best bet was to run a support down the entire length of the inside. Use 1 1/4″ screws and glue to attach the 1×2 to the inside as shown above. Notice how it’s flush with the end of the railing?

Comments

In reply to Playhouse Loft bed by Katieparker

Abzman

Tue, 07/30/2013 - 00:24

Full size bunk bed

Hi Katie,

Check out my posting, hope this helps. I built one with a Full size on top and single in bottom.

http://ana-white.com/2011/10/custom-playhouse-bunkbed

sstieh

Mon, 09/23/2013 - 05:38

Getting Started

I'm in the process of going over the plans as I would love to build this for my two daughters. I have a question about steps 3 and 4. In step 3 when attaching the legs to the plywood and rails do you screw in from the back to the front or do you counter sink the screws if you go from front to back?

Likewise in step 4 it says to "Attach the 1×3 to the front of the bed. Use 1 1/4″ screws and glue, overlapping the rails by 1″, hiding the joint between the railing and the plywood." How is this done so you can't see the screw heads in the finished product?

sstieh

Mon, 09/23/2013 - 05:38

Getting Started

I'm in the process of going over the plans as I would love to build this for my two daughters. I have a question about steps 3 and 4. In step 3 when attaching the legs to the plywood and rails do you screw in from the back to the front or do you counter sink the screws if you go from front to back?

Likewise in step 4 it says to "Attach the 1×3 to the front of the bed. Use 1 1/4″ screws and glue, overlapping the rails by 1″, hiding the joint between the railing and the plywood." How is this done so you can't see the screw heads in the finished product?

In reply to Getting Started by sstieh

Abzman

Mon, 09/23/2013 - 16:05

Steps 3 & 4

Hi,

For step 3, I put the screws in on the inside so they're not visible on outside.

Using the Kregg jig they will be counter sunk. You can purchase plugs and plug all the holes if you desire. But not sure it's needed.

Step 4: I used construction glue in some places including that piece and then finishing nails. So they were not visible. Additionally, I then used screws from the back to pull the piece in.

sstieh

Tue, 09/24/2013 - 09:58

Steps 3 & 4

This is very helpful. Thank you very much for the reply.

hhhmommy3

Mon, 11/18/2013 - 19:50

Full Plans

Could you send me the plans for this bed in a FULL?? Thank you so much!!! :)

hhhmommy3

Mon, 11/18/2013 - 19:50

Full Plans

Could you send me the plans for this bed in a FULL?? Thank you so much!!! :)

In reply to Full Plans by hhhmommy3

Abzman

Tue, 11/19/2013 - 10:47

Plans for FULL size

Unfortunately I did not take the time to document plans for my bad but I marked up my photos with the dimensions. You can click on my username or the image on the right to see my project. In it you'll find two links to the pictures and dimensions.

I hope that helps.

mercy4free

Sat, 08/30/2014 - 14:47

MDF or Plywood?

I am wanting this to last until my 3 year is at least a pre-teen (take the front off eventually). Do you advise using the MDF or plywood? I would think particle board would not last that long. I don't know anything about how durable MDF is. Also, I am a heavy person and of course I will have to get up there from time to time to make the bed or whatever. Suggestions?

teamrae

Sat, 10/25/2014 - 18:46

what to do different

I'm loving the idea of having a loft bed for my daughter. Her space is limited and would love to have more storage. With that said, while these directions are EXTREMELY helpful, I'm not to interested in creating an entire under the bed play area. And the thought of having her that high kinda scares me.

What would I do differently to maintain the sturdiness of the structure if I wanted to create a smaller under area play and add in maybe a small dresser or shelf (without having separate pieces)?

Thanks

LaRae

cdavis326

Wed, 06/10/2015 - 11:30

Has anyone made this bed taller?!?

Has anyone tried to make this bed taller to allow for a taller playhouse area under? Do you think this would be possible? Love this bed but I would like to have more clearance on the bottom. Any advice or thoughts appreciated!

Breezwest

Tue, 09/01/2015 - 11:52

Full size

Can I please get the plan for this bed in the full matteress size. I can't seem to find it under plans.

Thanks!

Breezwest

Tue, 09/01/2015 - 11:53

Full size

Can I please get the plan for this bed in the full matteress size. I can't seem to find it under plans.

Thanks!

Schwartzdog69

Sun, 12/06/2015 - 18:19

Weight limit

Does anyone know what kind of weight limit this has?

MissesErbstösser

Sat, 01/02/2016 - 10:39

Hello from Germany everyone :

Hello from Germany everyone :)

We love love love this Bed!! And we want to build it.But we ot problems to covert the mass in meter.

And we got also problems with the Shopping List.

HOPING FOR HELP!

For what as example is 7 – 1x2s, 8′ long standin for ?

Thank you so much

kate

Theresa V.

Sat, 01/02/2016 - 12:36

@ Kate aus Deutschland

Hallo Kate,

Ein 1x2 steht fuer ein Brett das 1 inch tief x 2 inch breit ist. Als Beispiel 7- 1x2s 8' long bedeuted 7 Bretter, jeweisl 1inch tief, 2 inch breit und 8 foot lang. 1 inch sind 2.54 Zentimeter. 1 Foot ist 12 inches oder 30.48 cm. Ich hoffe das hilft ein bisschen weiter.

Allerdings ist vielleicht auch zu beachten dass die Bretter im Baumarkt nicht wirklich die groesse haben. Ich hab mal eine liste gefunden (Nominal groesse ist wie es genannt wird, Actual ist die eigentliche Groesse und Metric ist was Deutsche Masse cm...):

http://mistupid.com/homeimpr/lumber.htm

the bavarian

Sat, 01/02/2016 - 13:01

@ Kate aus Deutschland

Hallo,

nur noch zur Anmerkung, da evtl. die Frage auftauchen wird:

' steht für foot (Fuß oder Zoll in Deutschland)

" für inch

Schönen Gruß

MissesErbstösser

Sun, 01/03/2016 - 11:15

Vielen Dank

Oh vielen lieben Dank.

Jetzt sind wir schon weentlich weiter. Im Baumarkt waren die Herren leider völlig ahnunglos.

Nur noch eine Frage:

Für was steht 3/4 ?

2 Platten von 3/4 MDF .

Mit lieben Grüßen

Kate

manolo2712

Mon, 06/27/2016 - 23:45

Sketchup plan

Hi Everybody,

My daughter saw this bed and since then every day she asks me to build it :-)

I wondered if there was a place on the website where I could download the sketchup plan ?

Thanks!