Using cedar fence pickets, you can make these beautiful planters for about $20 each! Our plans include step-by-step diagrams, shopping and cut lists, and dozens of reader submitted photos and success stories.

We also have plans for a taller, more modern planter, a cedar ladder planter (also using cedar fence pickets!) and lots more planter projects here.

Pin For Later!

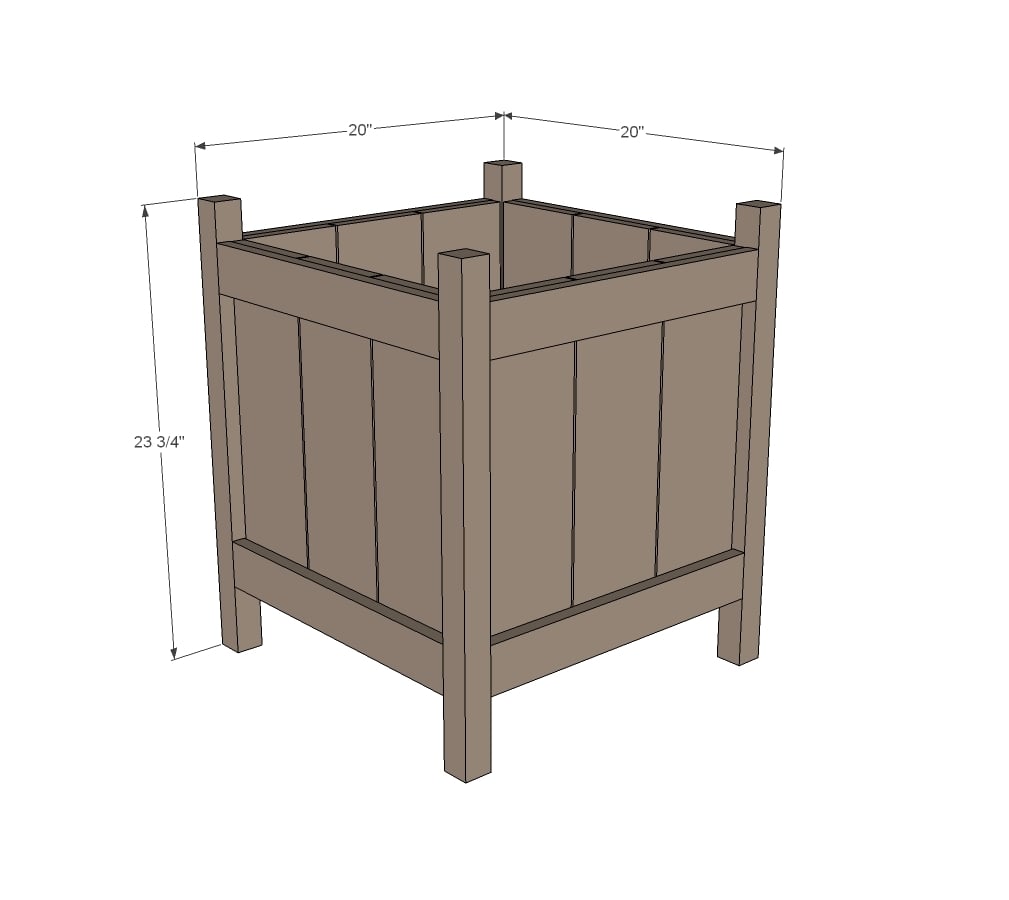

Dimensions

Dimensions shown above.

Preparation

Shopping List

- 2 - 1x3 @ 8 feet long

- 1 - 1x2 @ 8 feet long

- 3 - 5 1/2" wide x 72" long cedar fence pickets

- 1 - 2x2 @ 8 feet long

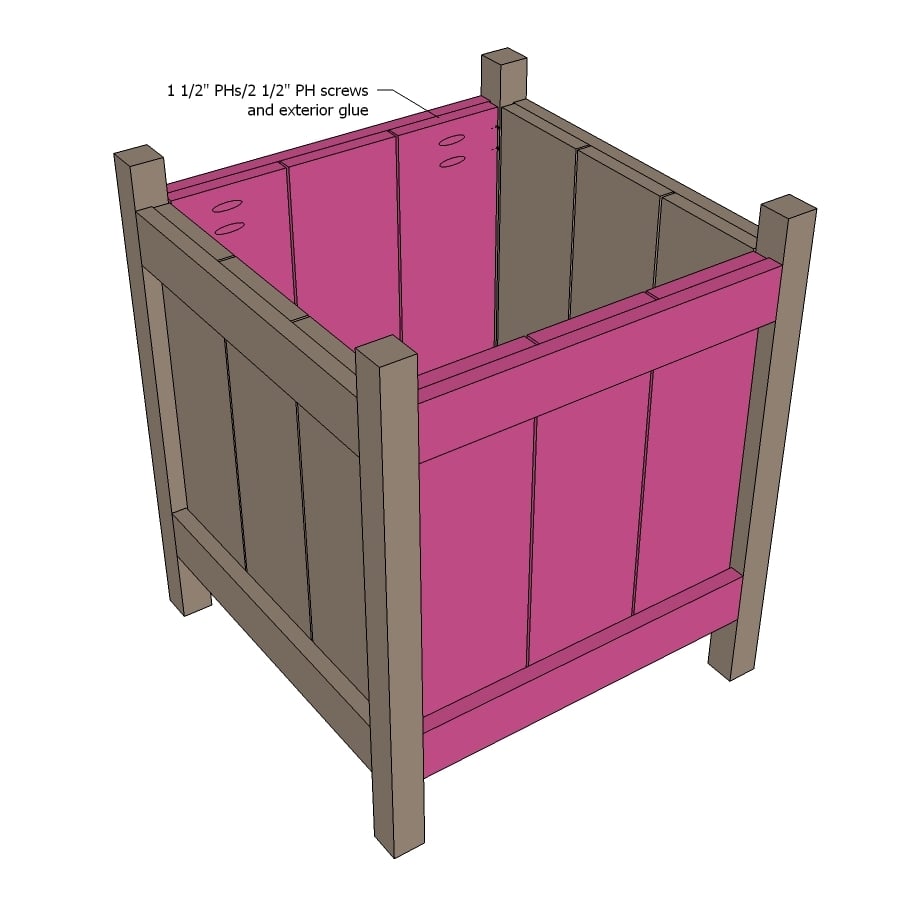

- 2 1/2" exterior pocket hole screws

- 1 1/4" exterior screws or galvanized nails

- exterior wood glue

Cut List

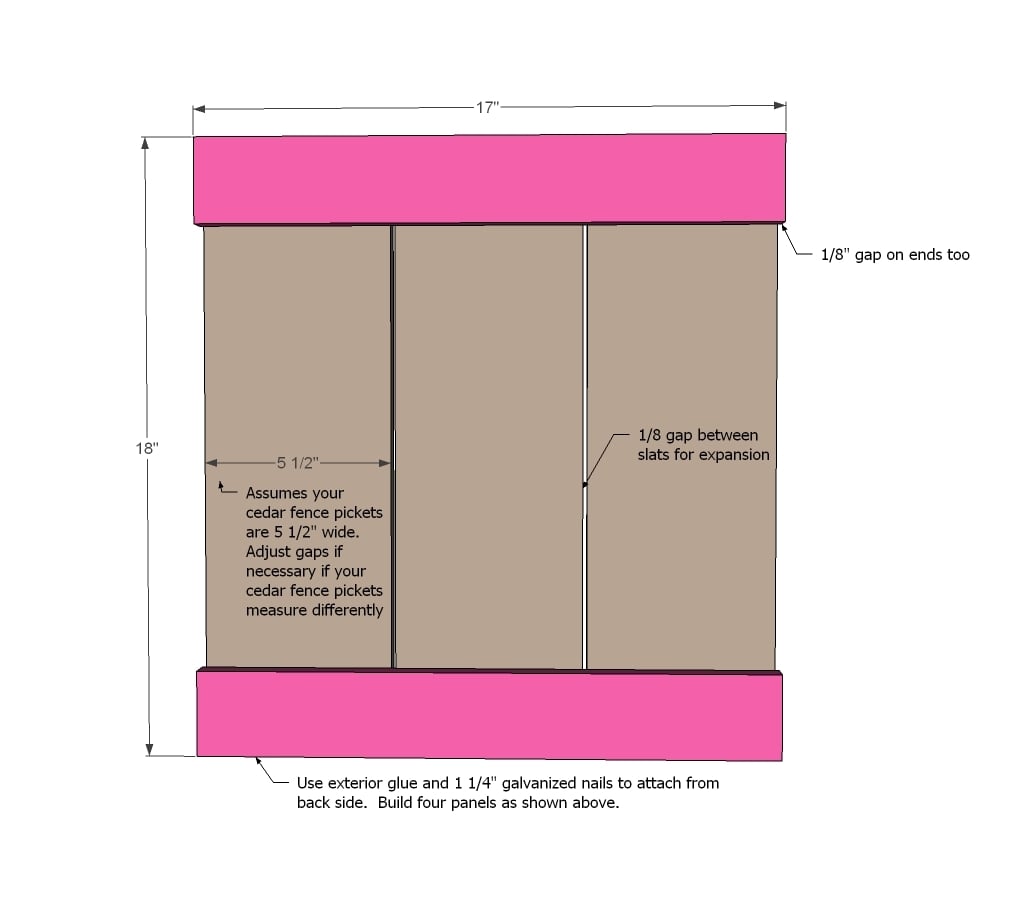

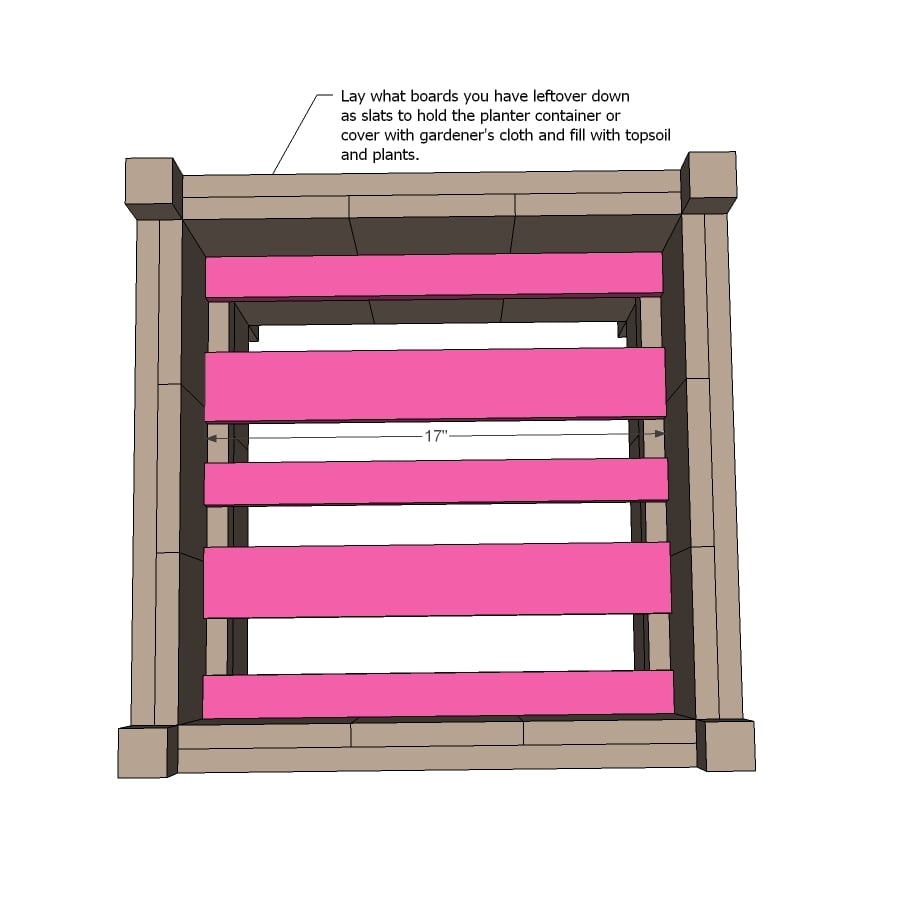

- 10 - 1x3 @ 17"

- 5 - 1x2 @ 17"

- 4 - 2x2 @ 23 3/4"

- 12 - cedar fence pickets @ 17 3/4" long (shortened by 1/4" from diagrams to allow for saw blade width and dog eared end)

Instructions

Step 1

Step 2

Step 4

Project Type

Room

Seasonal And Holiday

Comments

Andrew Malizia (not verified)

Wed, 08/08/2012 - 13:07

Neat project Ana. These will

Neat project Ana. These will tie in nicely with my short 30" cedar fence around my front porch I just built. I even have 16" cedar boards leftover from my cuts.

Error: Cutlist: 10 - 1x3 @ 17" (You've listed 1x8)

Thanks again!

In reply to Neat project Ana. These will by Andrew Malizia (not verified)

Ana White

Wed, 08/08/2012 - 15:03

Thanks for the catch!!! Will

Thanks for the catch!!! Will fix now. Thank you!

Kaila (not verified)

Wed, 08/08/2012 - 13:16

Alas...

...Cedar Fence Pickets don't seem to exist in my part of the country! I have a friend that works for Blue and he says they don't actually carry cedar in this region (central PA) in anything but pre-fab fence sections and corner posts. :-(

Guess I'll have to go the more expensive independent store cedar board route for my planters and raised beds.

orangesugar

Thu, 08/09/2012 - 08:24

Neither orange nor blue carry

Neither orange nor blue carry cedar fence pickets in my area (CT), I've looked multiple times.

vic b

Thu, 08/09/2012 - 12:44

cute

cute

Back Woods Woo…

Tue, 10/30/2012 - 22:08

Problem

I have a small problem. I have my 1/8" gap on all sides like the plans say, but as soon as I put my PH screws in the gap goes away. That even after I glued it and nailed it. So my gaps in the middle are no longer 1/8". But it still looks good even with the bigger gap, but I'll post some pictures as soon as I finish it.

Monique (not verified)

Sat, 12/15/2012 - 17:21

Planter Cost

I absolutely love your website. I'm so excited to get started on a few of your plans. You're any inspiration. Is the budget or $20 the cost per planter?

Continued blessings,

Monique

mybartmart

Sun, 04/07/2013 - 13:15

planter trouble

Well for me the 1/8th of an inch over on each end didn't work when attaching the 2x2's it made them buckle a bit inward. I think next time I would just make it flush. They are very sturdy when done and look great in different finishes.

JavaJoe

Wed, 06/11/2014 - 14:29

Smaller, more finished version of these cedar planters

I used the main plan for ideas, but opted to use 3.5 inch pickets instead of the 5.5's, which allowed for a smaller planter that wasn't as big. Also chose to miter 1x3s for the top which I think really finishes it off. Used cedar for everything, including the one bys. Sanded everything with a belt sander to 220 grit.

Assembled using a pneumatic staple gun from the backside, then finished with exterior wood screws so nothing would show.

For the finish, I used minwax golden pecan plus three coats of poly inside and out (much faster to treat all the boards first before cutting and assembling), to keep the rain out! Finished size was about 17x17. Tile spacers work great to keep the gaps even!

Thanks so much for the good idea... the wife loved it which is the most important thing (especially if you want to keep buying new tools LOL!!!)

Angel Rose

Sun, 06/15/2014 - 11:59

Protecting the bottom wood

Made two of these. Love them, but the slats I put in the bottom rotten/molded quickly. What have others used to protect the wood at the bottom or are most people using a plastic inserts?

Mary Helen

Wed, 06/25/2014 - 13:35

Made my first planter! Ya! Hoo!!

I thought I would make one planter just to get me started and give me enough courage to move on to bigger things (like a farmers table). Well, I made the planter with no problem. It was pretty easy. My husband liked it so much he contracted me out to our church who in turn wanted 4 more planters for there new wooden deck. So, I made 5 planters for my churches new wooden deck. I am so proud of my work that everytime I go to church I tell someone new, Guess who made those planter? Duh! Me. Yep, I made them all by myself. Thanks Ana for the plans!!

LYoung26

Sun, 02/15/2015 - 17:01

Step 1 instructions

These look great! I have a question though. On step one it says, "attach at bottom and top with 1 1/2 inch ph screws and 2 1/2 phs screws." There aren't 1 1/2 ph screws in the shopping list. The 2 1/2 Pocket hole screws are for the pocket holes right? And then we attach the cedar planks to the 1x3's from the inside with 1 1/4 pan head screws? Is that right?

Sue Hill

Wed, 04/22/2015 - 09:17

Where to buy cedar pickets?

I just love all your projects using these pickets. I have tried all over CT to find them but no luck. I've been using pressure treated pickets 1x6x6' but would rather find the cedar. Anyone have a source?

KevinOBrien1130

Fri, 06/12/2015 - 16:05

whitewood boards on the trim

Hello,

What kind of wood is the whitewood boards on the trim? Is it pine?? And is that all the boards in this plan besides the cedar slats?

Thank you,

Kevin

In reply to whitewood boards on the trim by KevinOBrien1130

Ana White

Sun, 06/14/2015 - 13:30

Hi Kevin,

Hi Kevin,

Yes exactly and pine.

KevinOBrien1130

Fri, 06/12/2015 - 20:37

Whiteboard

Forget it. I found out that it is just basic pine lumber. Thank you..

bclute

Wed, 12/02/2015 - 19:23

Stain

I built these with pine and stained with steel wool and vinegar. They turned out good, but I would like to use them outside. Should I put a coating on them for protection (one that has a matte finish), or will they be ok?

Mark1115

Thu, 12/31/2015 - 14:35

More cedar

An alternative to the 1x3 pine would be to rip a cedar picket in half. As the cedar pickets are 5.5 inches wide, you wouldn't end up with 3 inches per board, you get something like 2.625 inches in width for each board. But I think the advantage is the cedar pieces will weather better than the pine.

For the verical slats, if each picket is 6 feet in length you should be able to get 4 boards per picket, each 18" in length - helpful to those people wanting to build a bigger box. If wanting to conceal the dog ear, put the dog ear end on the bottom of the planter and it will be hidden from everyone except the gophers.

It may be easier to attach the cleats (step 4) prior to building and fastening the box on all four sides, the advantage being you can screw or nail the cleats while each side of the planter is on a flat surface, and then do the tilt-up. If attaching the cleats after the box has been built, it creates a somewhat awkward angle for hammering or screwing in that you don't have a direct downward view on your fasteners while attaching the cleats.

BrandyK

Sun, 04/03/2016 - 16:51

First pocket hole project

This is my first project with pocket holes....and I have already messed it up during step 1. I attached the fence pieces to the 1 bys with your & 2 screws for each board at top & bottom (4 screws per board). I now do not have enough room for the pocket holes :(. I am hoping I can correct this by removing the screws that are in the way. I wanted to mention this to try to help another newbie. Ana, thanks for sharing so many free woodworking plans. I hope to learn from this one & try several more.

Wayne Oglesby

Sun, 05/22/2016 - 12:40

Connecting legs

Am I reading the instructions attaching legs by drilling 1 1/2 pocket holes but use 2 1/2 screws? FWIW I nearly cut the end of my thumb off getting in hurry cutting legs 2 weeks ago. Surgery this week. Anxious to finish and build more.

Wayne Oglesby

bfroeschle17@g…

Tue, 05/21/2019 - 19:13

Hello Anna, How do you…

Hello Anna,

How do you download the plans?

dwtdc

Wed, 05/06/2020 - 10:57

Planter

Did you plug the PH drilled or leave open