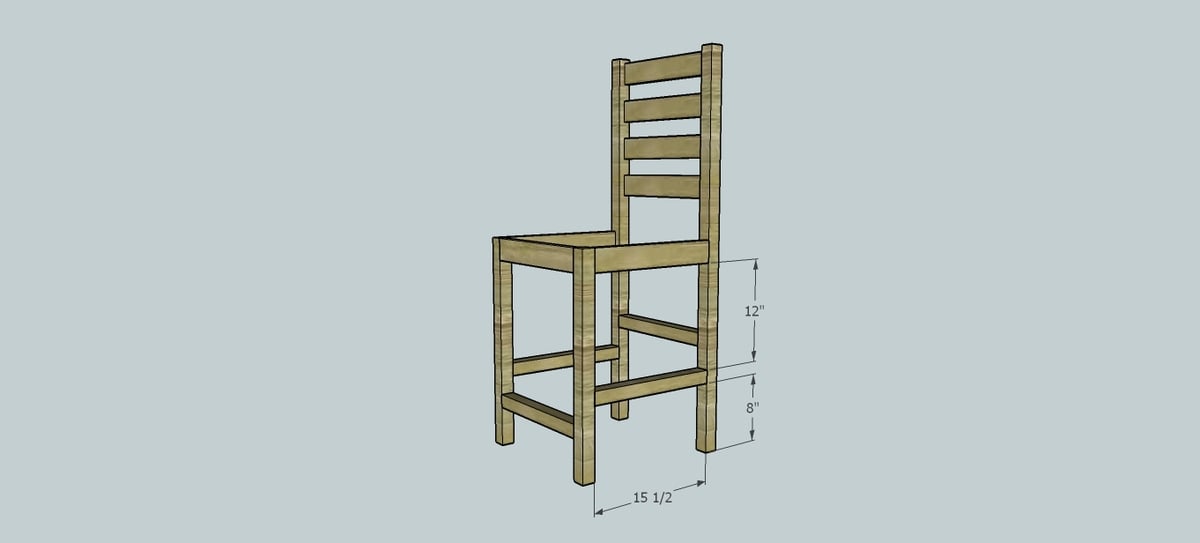

Counter Height Bar Stool

Preparation

2 by 2 - 8 ft lengths - Qty 3 1 by 2 - 6 ft length - Qty 1 1 by 3 - 6ft lengthh - Qty 2 1 by 4 - 8 ft length - Qty 1

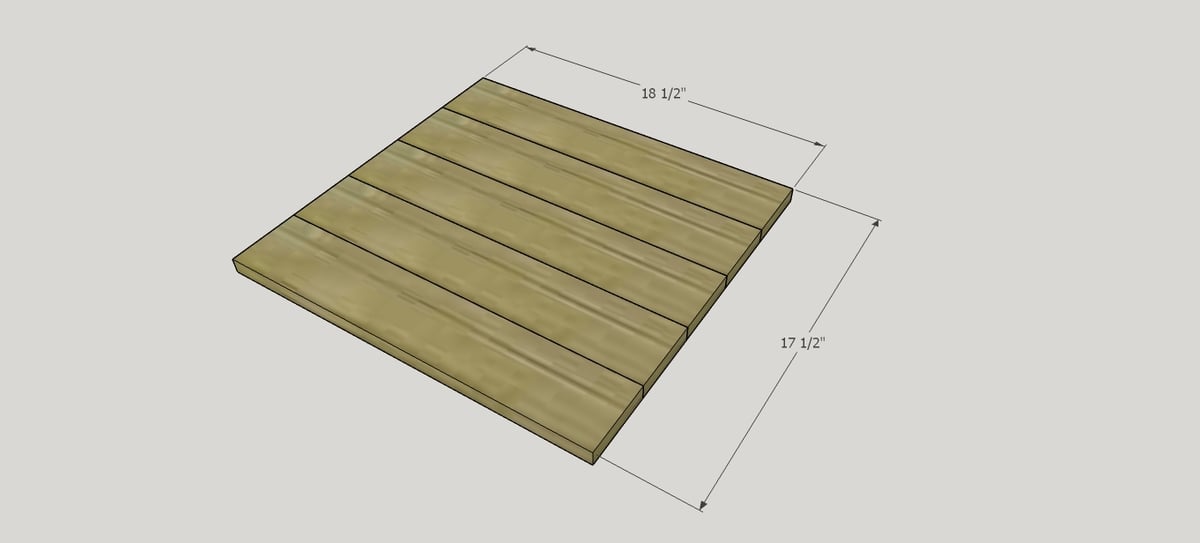

2 by 2 24 2 Front Legs 2 by 2 45 2 Back Legs 2 by 2 14.5 2 Bottom rails for front and back 2 by 2 15.5 2 Bottom rails for sides 1 by 2 14.5 1 Seat trim for back frame 1 by 3 14.5 6 Rails for front and back 1 by 3 15.5 2 Top rails for sides 1 by 4 18.5 5 Seat

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

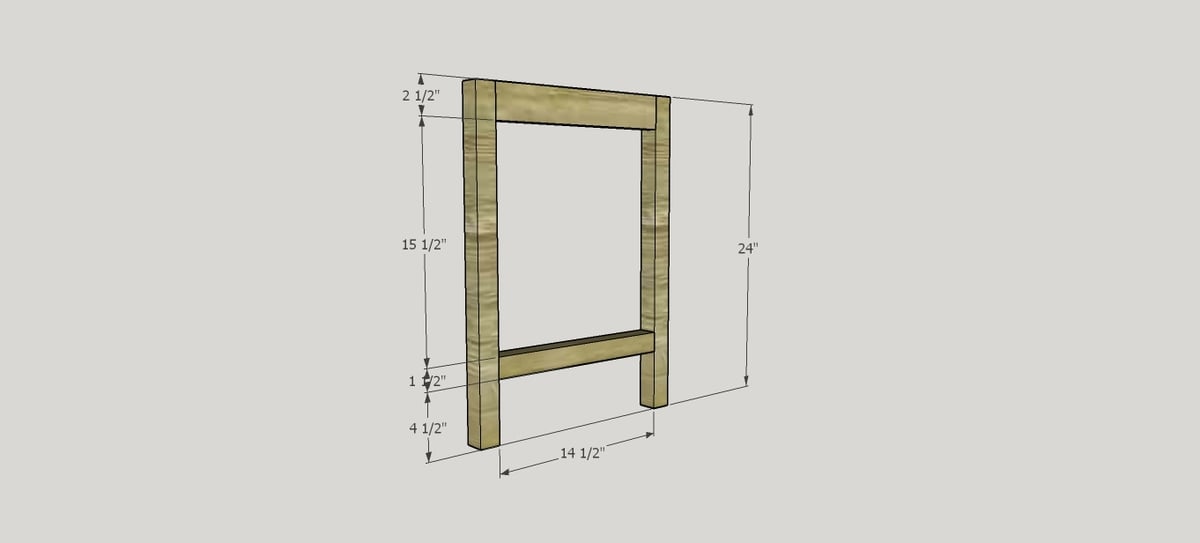

Step 1

Join the two shorter legs measuring 24 inches together using one of the 14 ½ inch 1 by 3s and a 14 ½ 2 by 2. I placed the bottom edge of the 2 by 2 rail 4 ½ inches up from the bottom of the leg and drilled the pocket holes for the 2 by 2s on the bottom edge so they are hidden from sight. The 1 by 3s will be hidden by the seat so you won’t see the pocket holes on the inside once seat is fitted. I decided to make the outside of the top rail flush with the outside of the legs rather than inset.

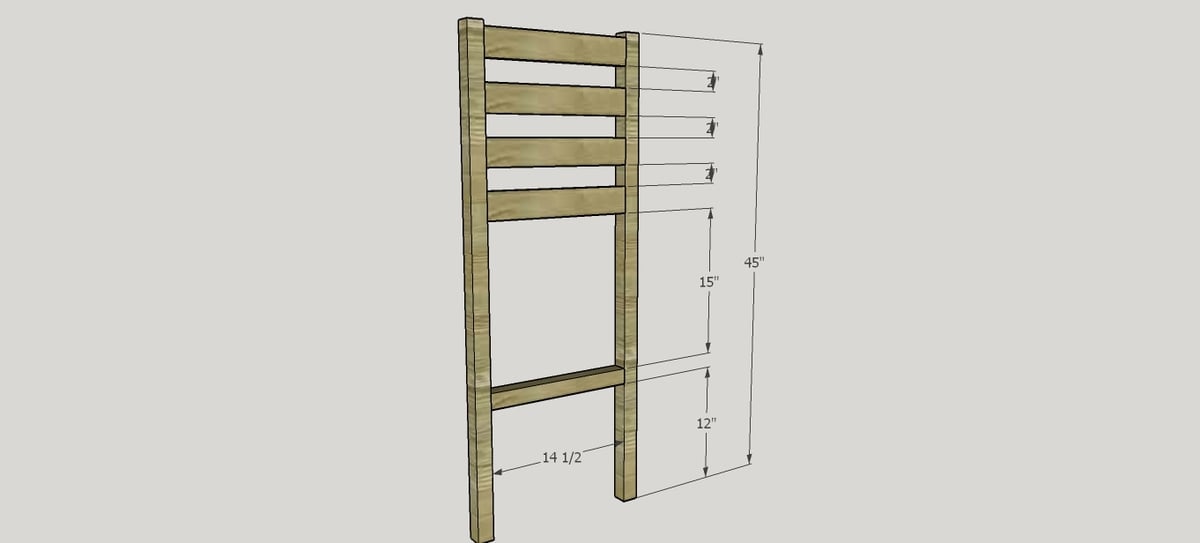

Step 2

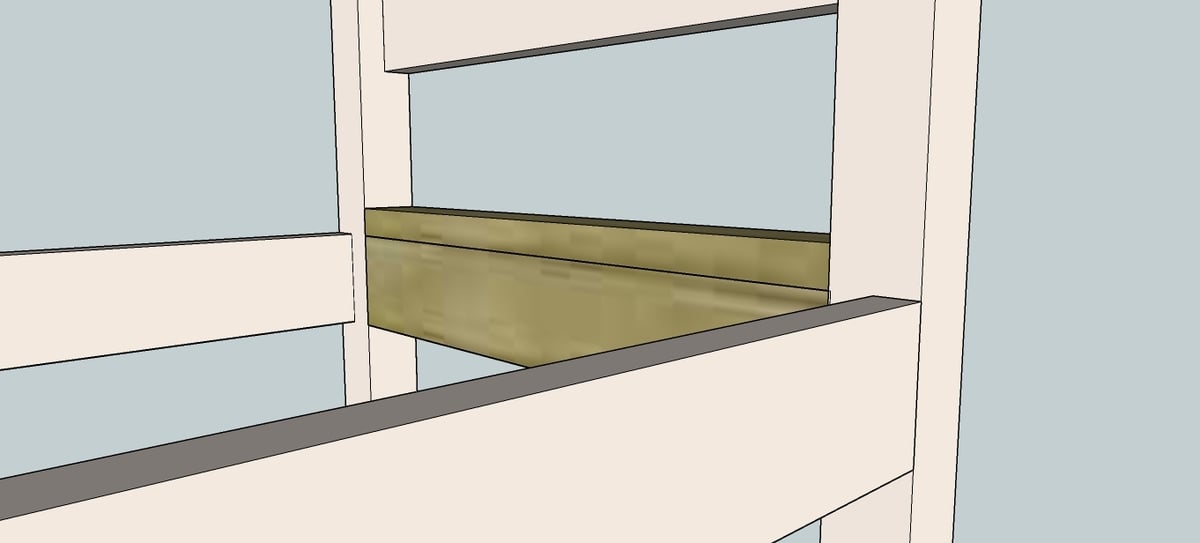

Join the two longer legs measuring 45 inches together using 4 of the 14 ½ inch 1 by 3s and a 14 ½ 2 by 2. I placed the bottom edge of the 2 by 2 rail 12 inches up from the bottom of the leg. I spaced the rails out by 2 inches which left a gap of half an inch from the top of the top rail to the top of the leg. Tip : Cut two scraps of wood two inches long and use them as spacers when fitting the back rails If you look at my finished photo, the diagram below actually shows the back of the chair. The part you lean against actually has the 1 by 3s inset by ¾ inch (so they are flush with the back). I put my pocket holes on the back side and made sure I filled, sanded, filled, sanded and repeated until happy the holes would not show. It is time consuming but worth the end result.

Step 3

Step 4

Step 6

Step 7

Sand well to smooth out the joints and remove any wood glue residue. If staining then apply Pre-stain and your choice of stain or paint as desired.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

RobA

Thu, 06/16/2016 - 12:05

standard height

What leg length for a standard table height? Thanks

nitared66

Fri, 08/26/2016 - 14:21

Not enough 2x2s?

Am I crazy, or are there not enough 2x2s in the shopping list to cover the legs and rails?

Dmsmth

Fri, 02/23/2018 - 07:48

Weight limit

What is the weight limit on a stool like this?

beefster

Fri, 12/11/2020 - 08:06

When making seat do you…

When making seat do you pocket hole them all together or fasten them individually?

sylvialh

Tue, 12/15/2020 - 06:20

seat step missing instructions

I did glue and pocket holes. I didn't want to risk people getting their thighs pinched if there was any movement (an issue I had with the simple backyard series bench)

sylvialh

Tue, 12/15/2020 - 06:20

cut / shopping list format

Seems like the cut list and the shopping list are not properly formatted and makes it really hard to read as it's all in a row instead of a list

thanks for another great build, I'm really excited to build these with a molded plywood back. I'm using a 1/8 veneer and gluing them together to form the back rest.

ClrH2OFL

Thu, 07/22/2021 - 12:51

Materials (3) 2x2x8 (1)…

Materials

(3) 2x2x8

(1) 1x2x6

(2) 1x3x6

(1) 1x4x8

Cut List

(2) 2x2x24” Front Legs

(2) 2x2x45” Back Legs

(2) 2x2x14.5” Bottom rails for front and back

(2) 2x2x15.5” Bottom rails for sides

(1) 1x2x14.5” Seat trim for back frame

(6) 1x3x14.5” Rails for front and back

(2) 1x3x15.5” Top rails for sides

(5) 1x4x18.5” Seat