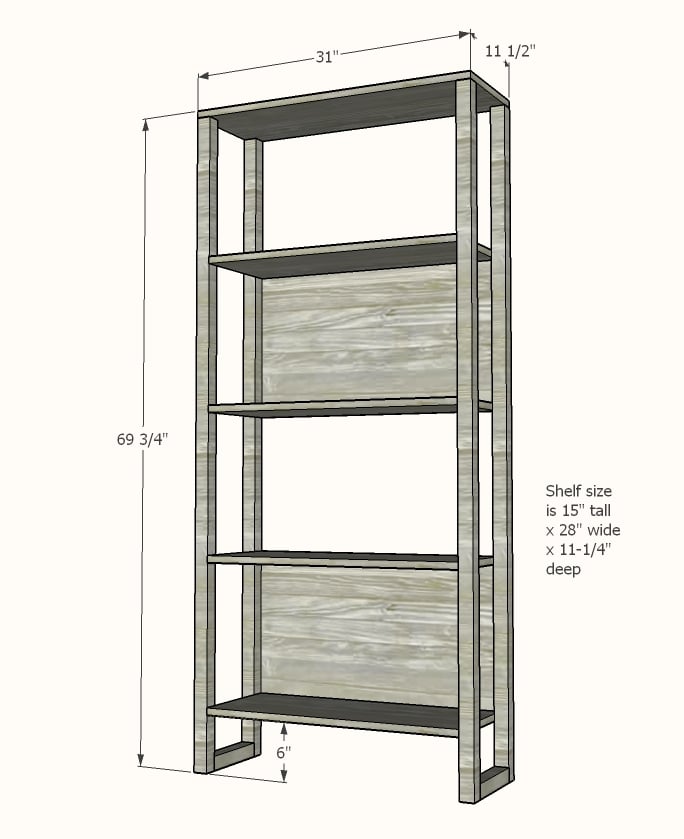

Build this gorgeous industrial bookshelf for just $30 a piece! Open bookshelf, narrow bookshelf. Beginner plans by ANA-WHITE.com

Pin for Later!

Preparation

4 - 2x2 @ 8 feet long

1 - 1x12 @ 12 feet long - do not cut in half for transport - it is better to cut as listed in cut list for transport

1 - 1/4" plywood panel 48" x 48" (or two panels 24" x 48" if easier to transport)

4 - 2x2 @ 69" - legs

2 - 2x2 @ 8-1/4" - bottom leg supports

1 - 1x12 @ 31" - top

4 - 1x12 @ 28" - shelves

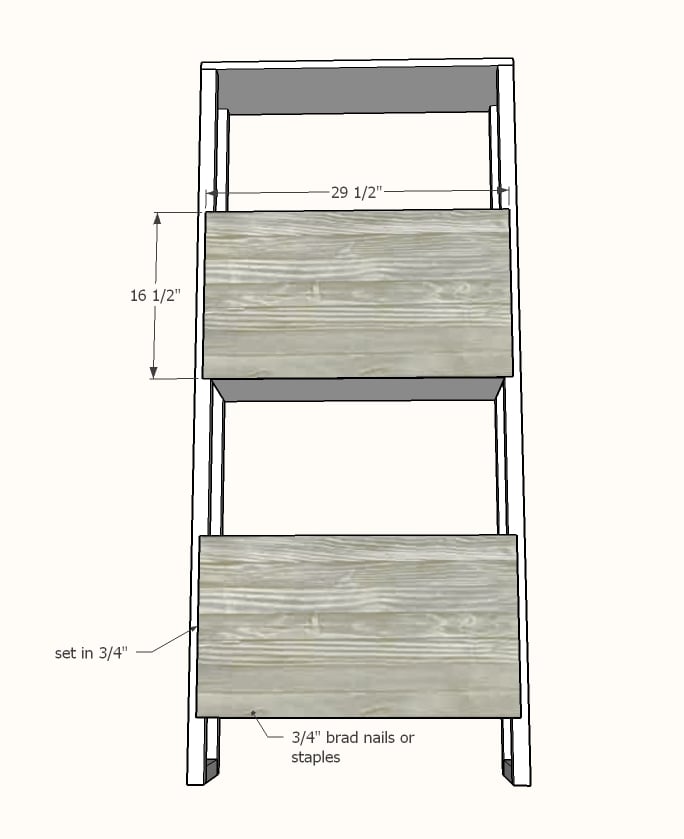

2 - 1/4" plywood @ 16-1/2" x 30-1/2" - back

Instructions

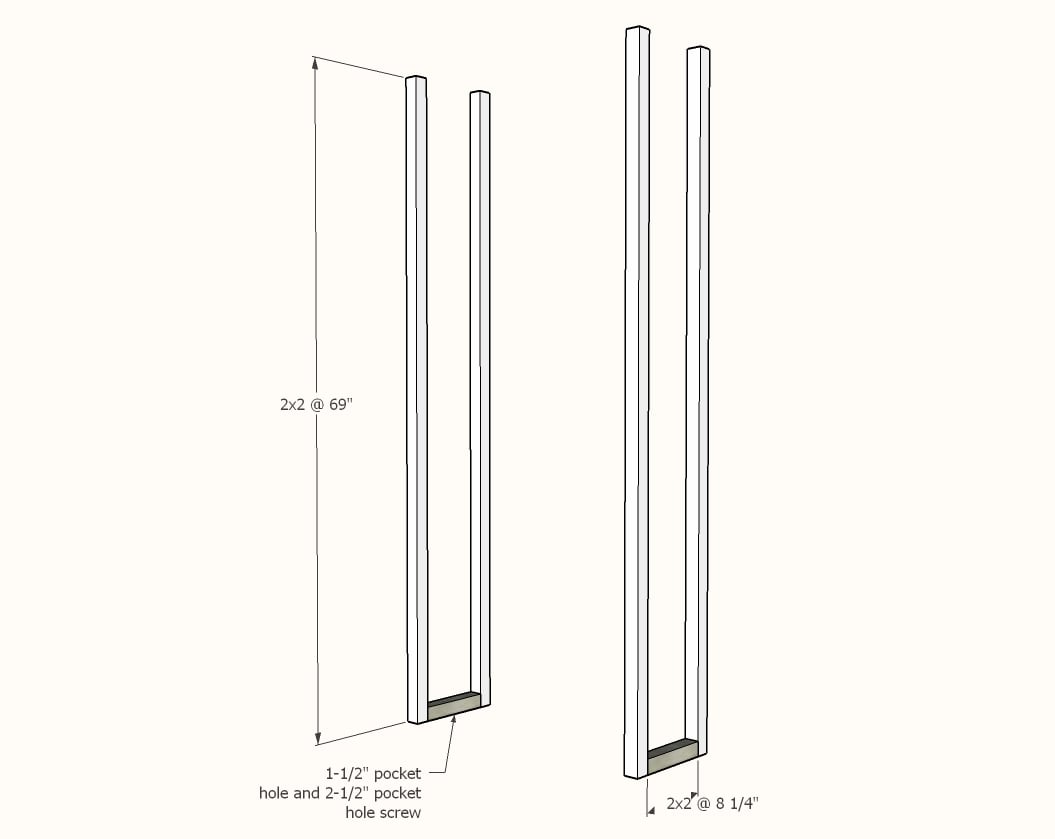

Step 1

Set your Kreg Jig to the 1-1/2" setting.

Drill a single pocket hole on each end of the small 2x2 pieces.

TIP: Before attaching legs, you may wish to drill a pocket hole for attaching the top on each leg (see next step). Also make sure you rotate legs so the pocket holes are placed on the back of the legs.

Attach to the legs at the bottom with 2-1/2" pocket hole screws and glue.

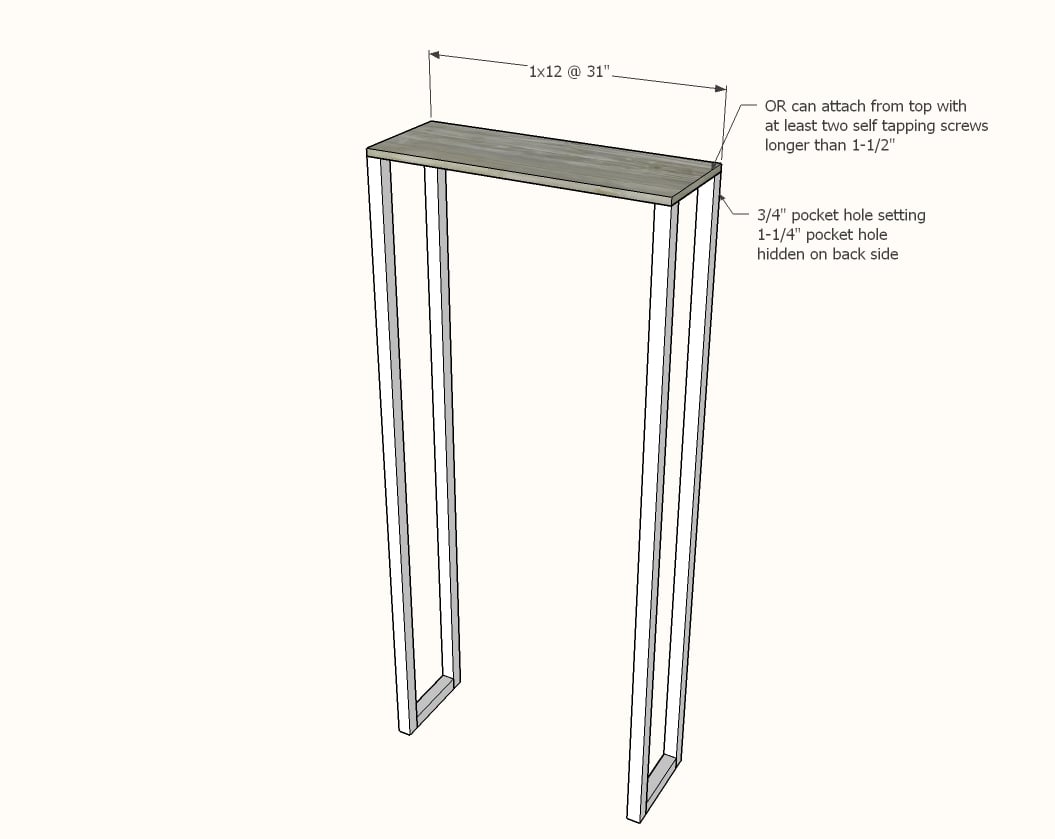

Step 2

The top can be attached with screws from the top or pocket holes on the back side.

If using screws from the top, you'll need at least two screws per joint, small, self tapping screws are best.

If using pocket holes, set the Kreg Jig to 3/4" setting (but the clamp set for 1-1/2" thick wood). Drill a single pocket hole on backs of legs.

Attach with 1-1/4" pocket hole screws to top.

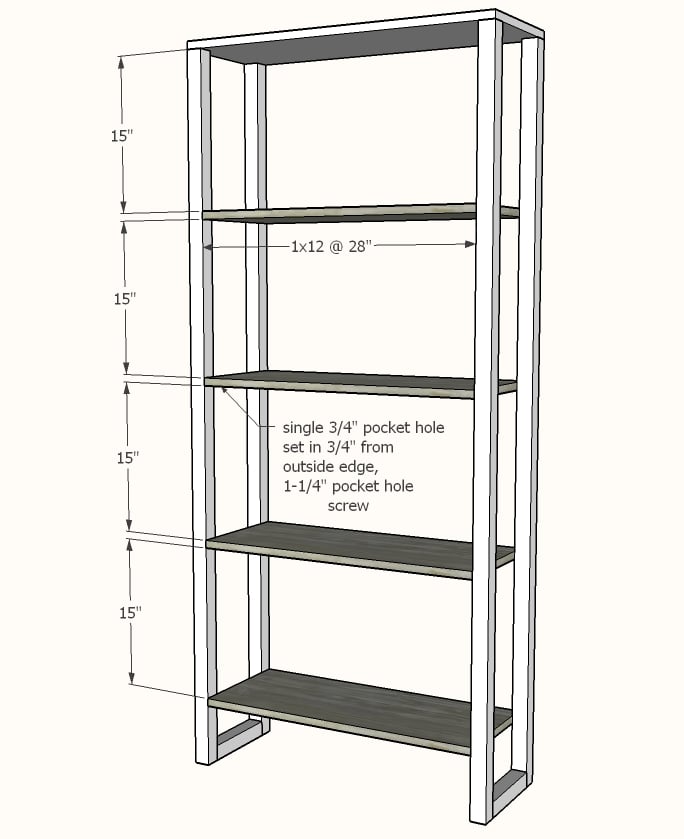

Step 3

Step 4

Make sure the project is square by taking diagonals of the outside corners, and making sure the diagonals match. If they don't match, adjust until they do by pushing the long diagonal corners together.

On back of project attach the 1/4" plywood panels with 3/4" brad nails or staples and glue, attaching to shelves and legs.

To prevent forward tipping hazard, attach to stud in wall on final installation with screws.

Comments

GLH5MHIL

Tue, 08/06/2019 - 15:39

Office Book Case project

Looking forward to this project to make one or two of them for my office/man cave

cajun custom

Fri, 06/12/2020 - 20:44

Shelves

The plan was easy to follow and my shelves came out nice.

lyds6382

Mon, 06/22/2020 - 20:45

Back pieces

Instead of just the two sections with backing, could you have some sort of lightweight piece that covers the entire back?