Build your own farmhouse style counter stools with free plans by Ana-White.com These gorgeous stools feature clean, simple lines that bring a wood accent to your kitchen without competing. Surprisingly comfortable with a well placed footrest and wide seat, yet still very sturdy, we can't wait to see how your stools turn out!

Collections

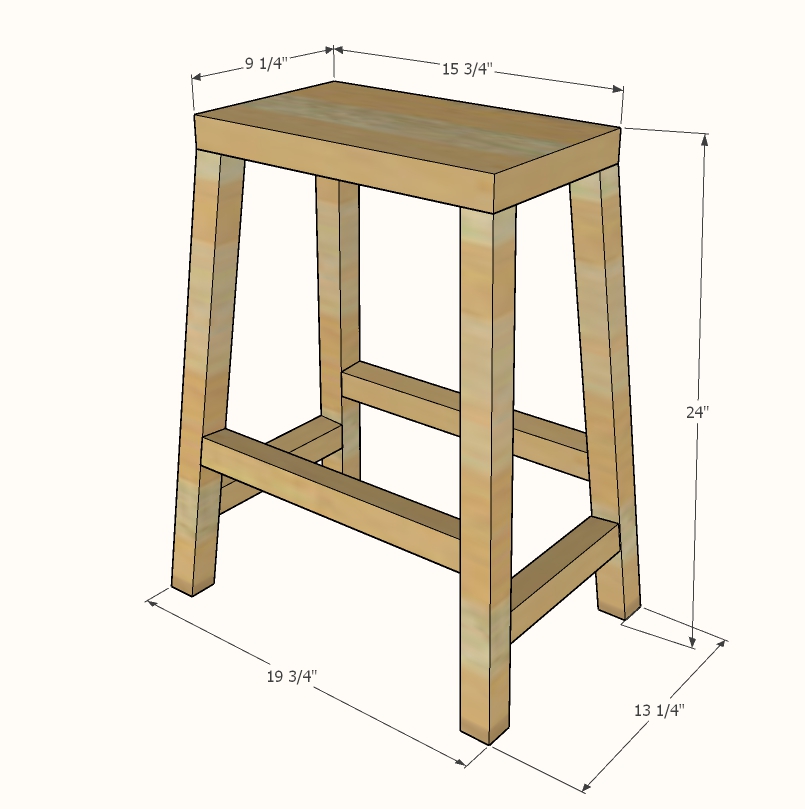

Dimensions

Suitable for counter height dining

Preparation

Shopping List

Shopping List per Stool

- 2x10 @ 16" long

- 2 - 2x2 @ 8 feet long (I used 2x2 furring strips)

- 12 - 3" long self tapping wood screws with star bit

- wood glue

NOTE: There will be about half a 2x2 leftover, so if you are making multiple stools you may be able to purchase less 2x2s

Cut List

Cut List Per ONE Stool

- 1 - 2x10 @ 15-3/4"

- 4 - 2x2 @ 22-5/8" both ends cut at a double bevel - 5 degrees angle and 5 degrees bevel - ends ARE parallel, longest point to shortest point measurement

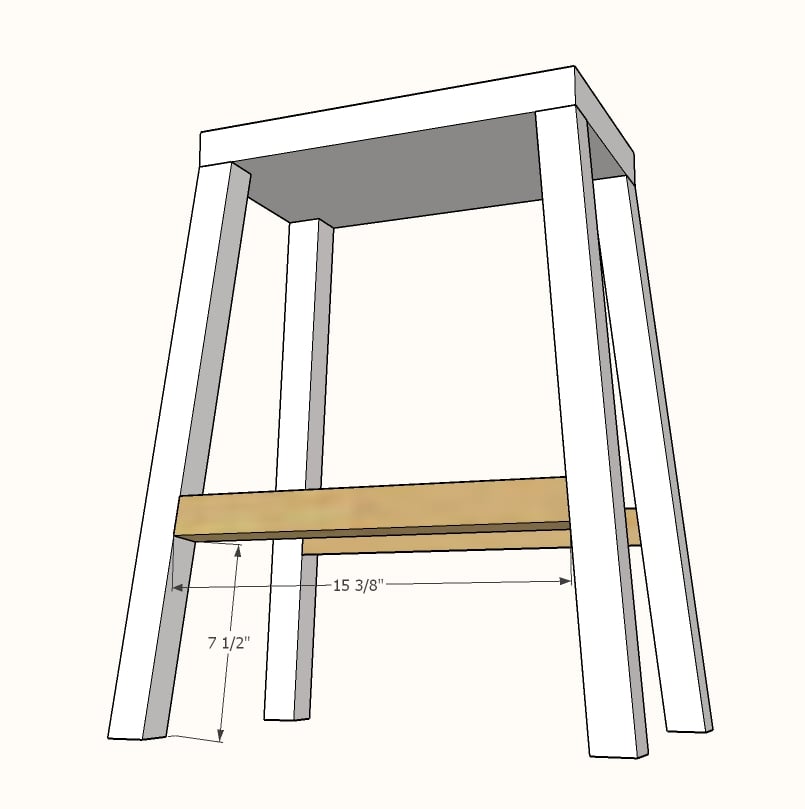

- 2 - 2x2 @ 15-3/8" - both ends cut at a 5 degree angle (not a double bevel), ends NOT parallel, long point to long point measurement

- 2 - 2x2 @ 9-1/2" - both ends cut at a 5 degree angle (not a double bevel), ends NOT parallel, long point to long point measurement

Instructions

Step 1

Step 2

Step 4

I recommend leveling feet to help adjust your stools for level if slightly out of square, and also protect your floors. These ones are about 50 cents a piece.

Comments

ladybug'13

Sun, 08/02/2020 - 09:16

Could you make these using…

Could you make these using pocket holes or would that make them less sturdy? Would love to do this but don't want to sacrifice structural integrity.