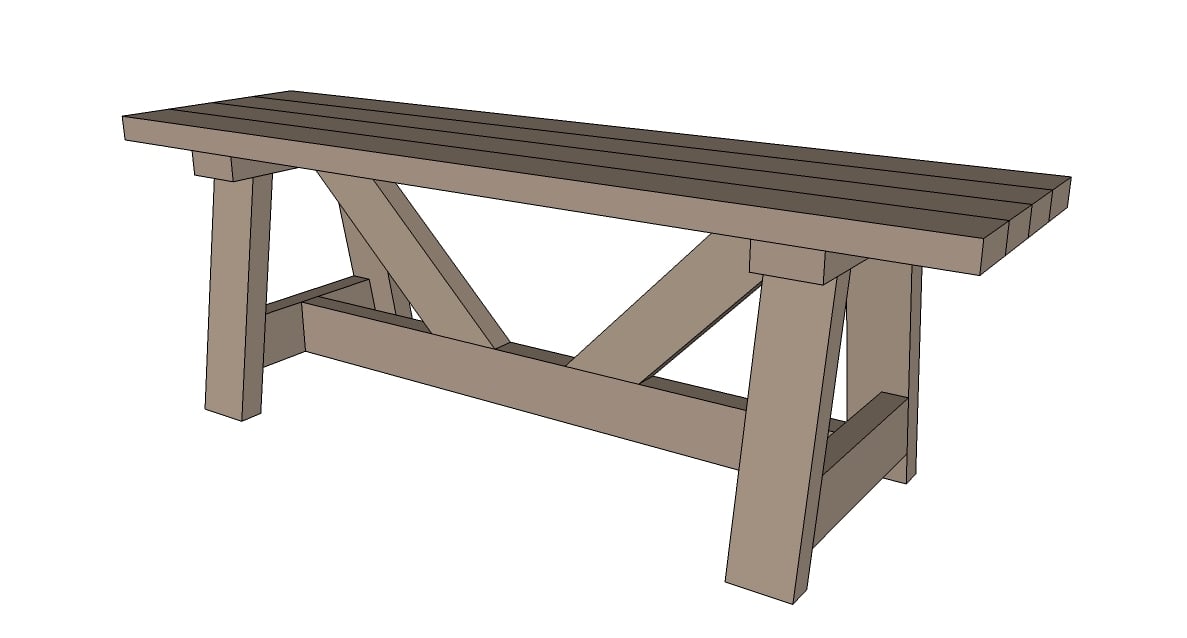

Make this sturdy and beautiful truss style bench with just 5 2x4s - we make it easy with step by step plans and diagrams.

Also build the matching table plans.

Collections

Pin for Later!

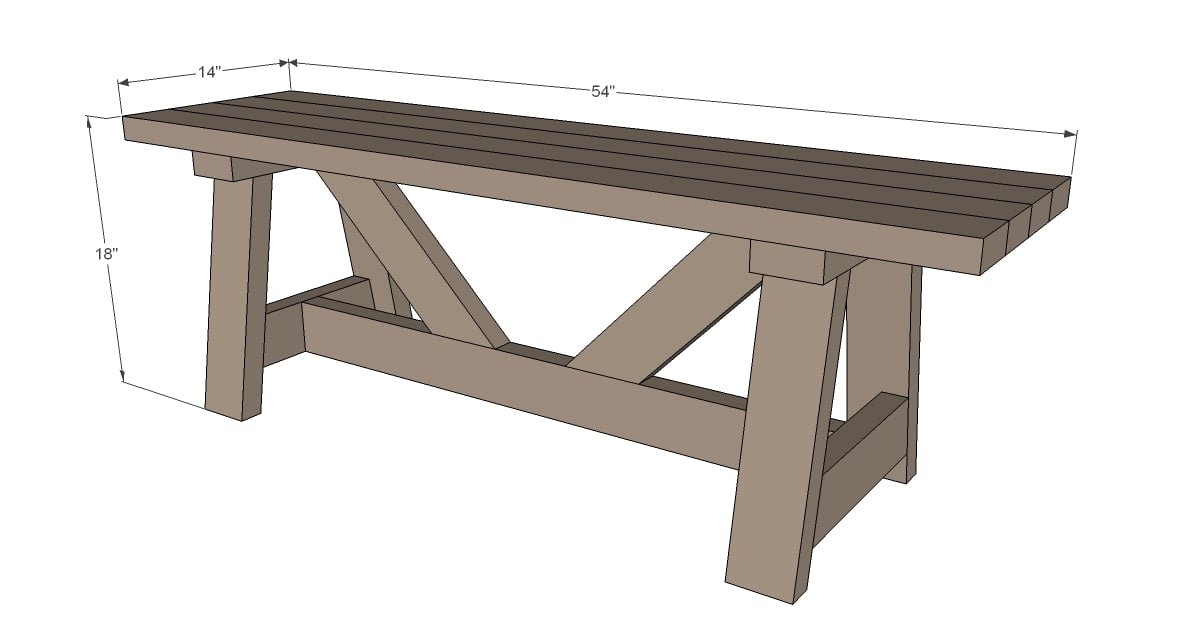

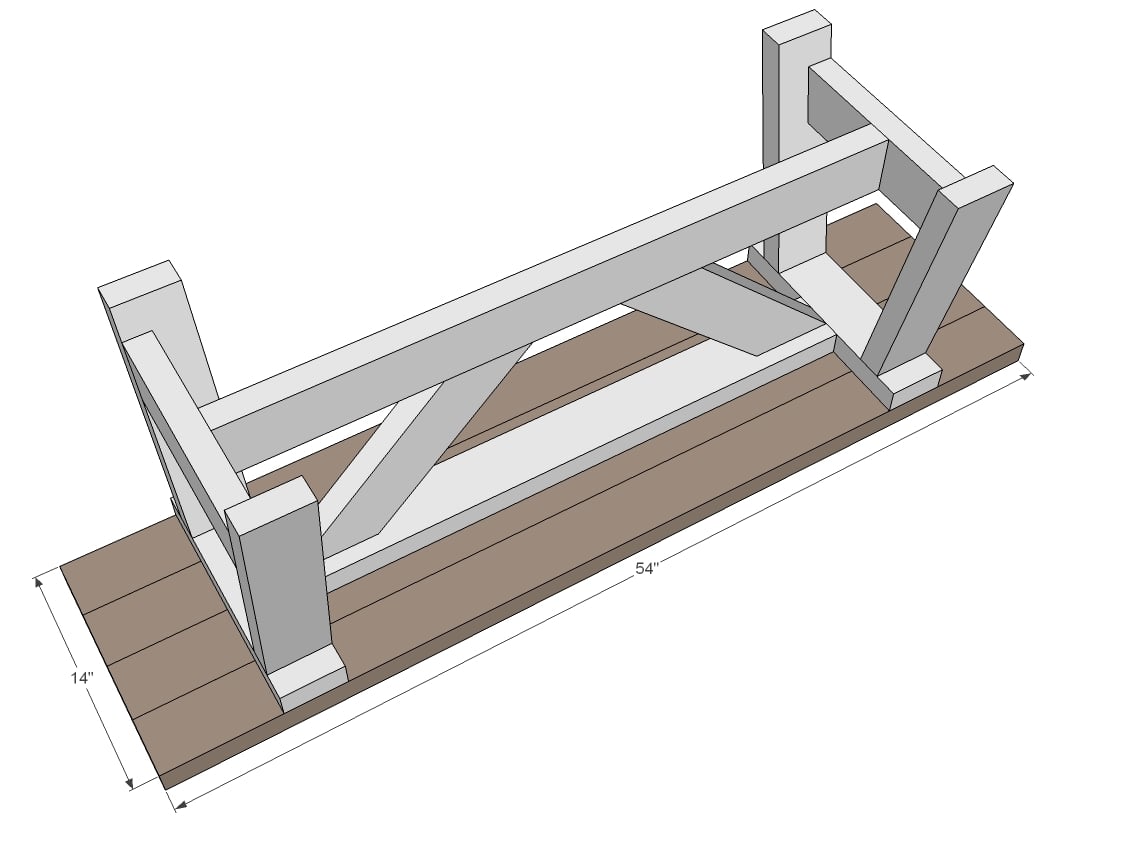

Dimensions

Dimensions are shown above.

Preparation

Shopping List

5 – 2x4 @ 8 feet long – cut longest boards first

2-1/2" self tapping wood screws (star bit)

Optional 1x3 under bench supports

Cut List

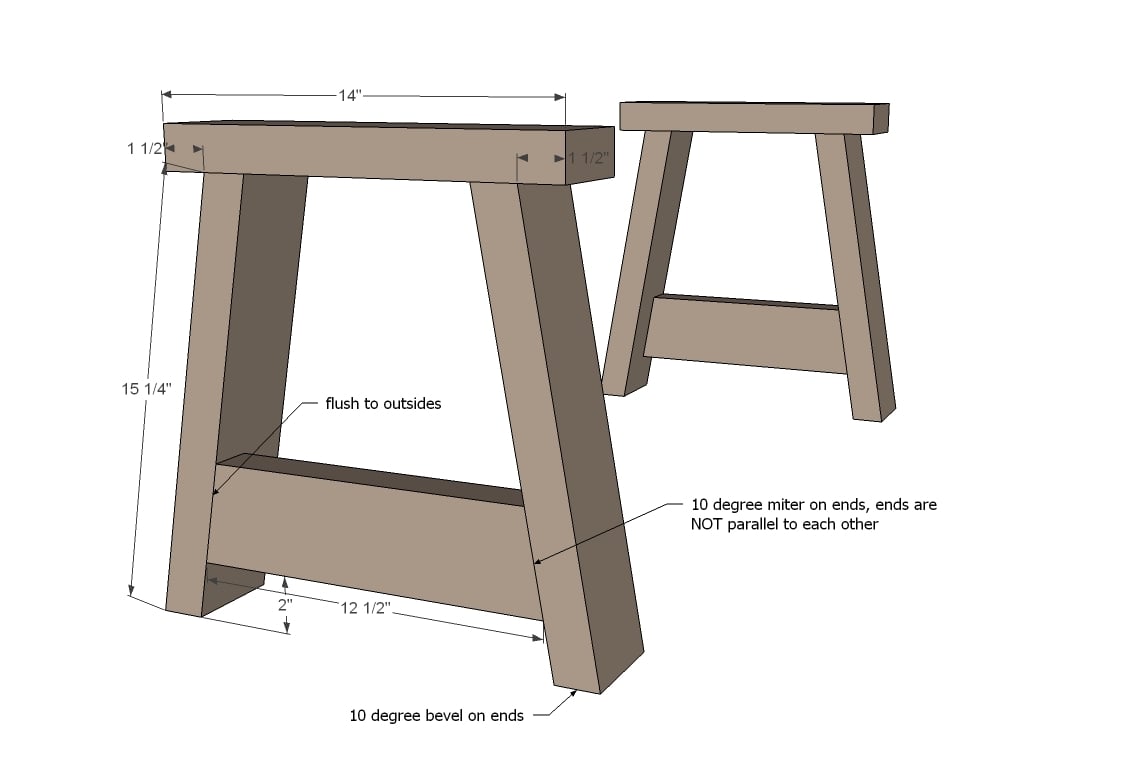

- 2 – 2x4 @ 14”

- 4 – 2x4 @ 15 1/4" – both ends beveled at 10 degrees off square, ends ARE parallel

- 2 – 2x4 @ 12 1/2" – long point to long point, both ends cut at 10 degrees off square, NOT parallel

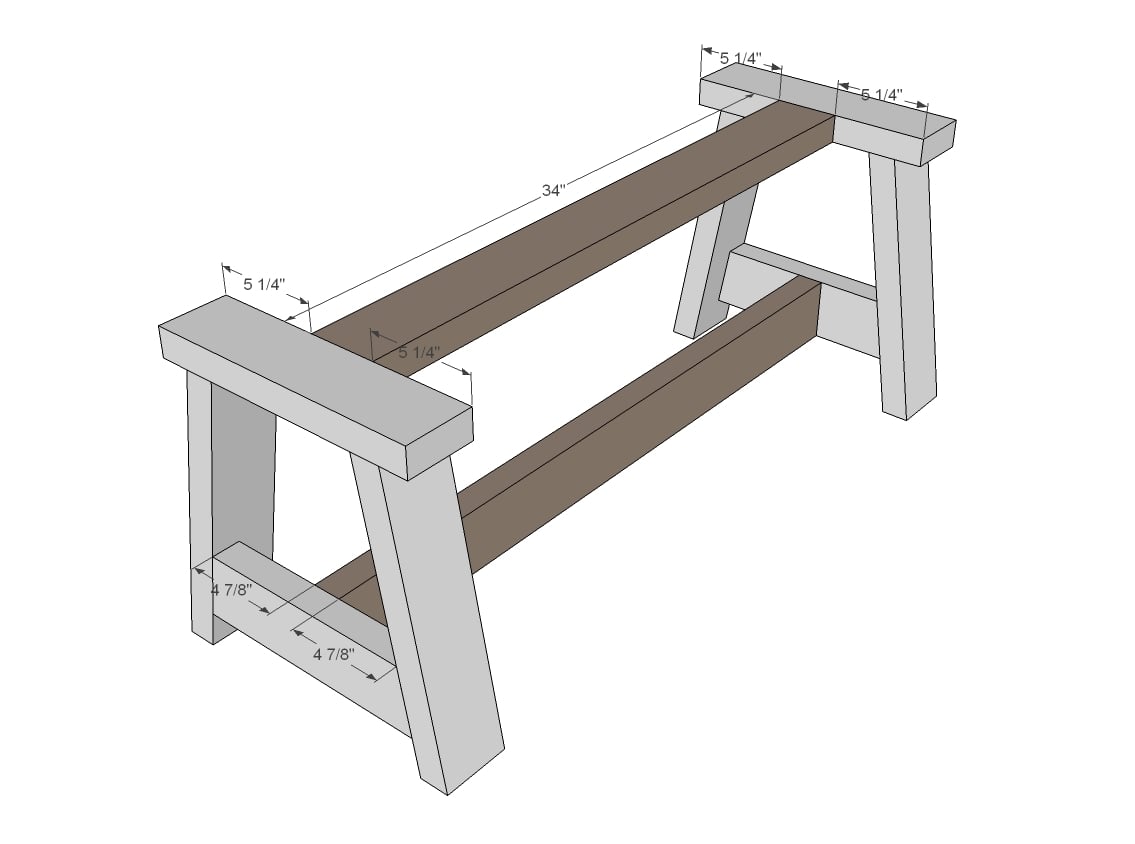

- 1 – 2x4 @ 34”

- 1 – 2x4 @ 38”

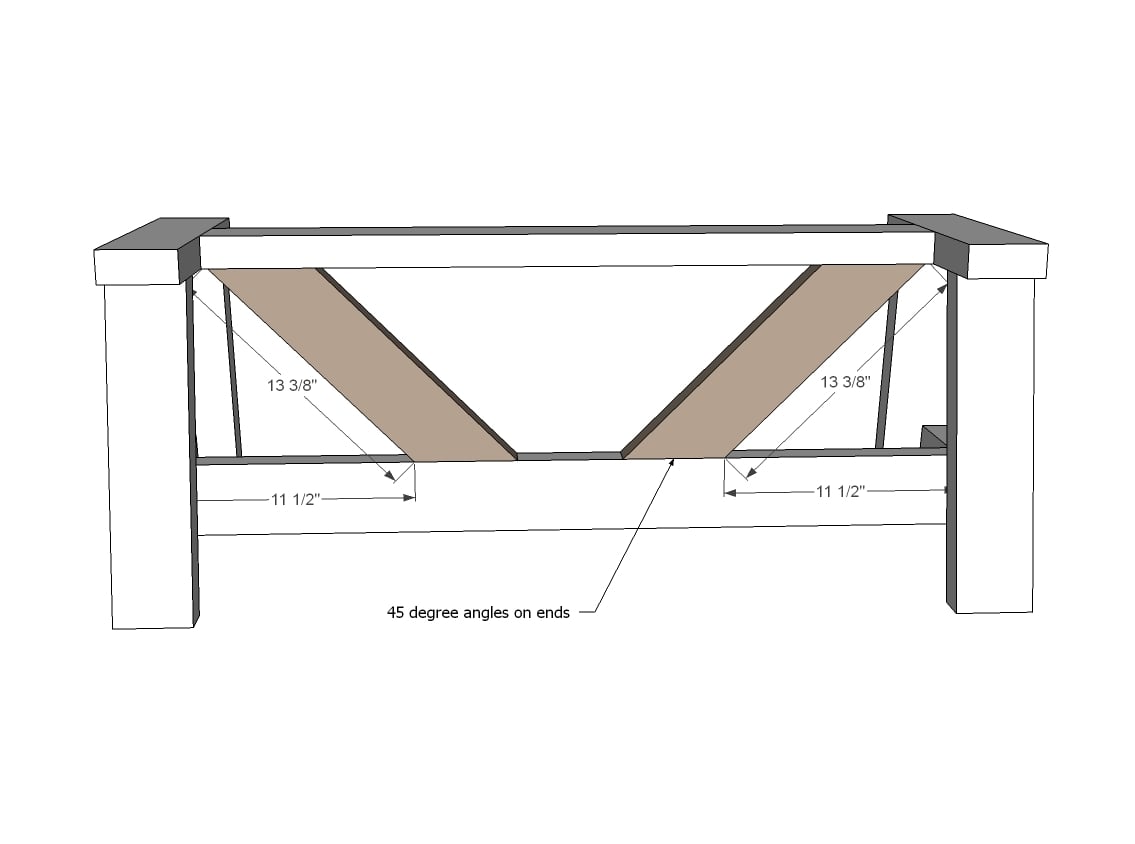

- 2 – 2x4 @ 13 3/8” (both ends cut at 45 degrees off square, ends ARE parallel)

- 4 – 2x4 @ 54”

Instructions

Step 1

Step 2

Step 3

Step 4

Finishing Instructions

Preparation Instructions

Fill all holes with wood filler and let dry. Apply additional coats of wood filler as needed. When wood filler is completely dry, sand the project in the direction of the wood grain with 120 grit sandpaper. Vacuum sanded project to remove sanding residue. Remove all sanding residue on work surfaces as well. Wipe project clean with damp cloth.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Project Type

Comments

whitney_smith

Thu, 04/26/2012 - 11:24

So simple and great and

So simple and great and CHEAP! Will be looking through my pile of wood.

RHgaijin2

Sun, 08/11/2019 - 06:59

Truss style bench

I made two of these benches over a weekend and posted a video of it on youtube at:

https://youtu.be/siTT2jxBsWE

I also have a brag post

RHgaijin2

Tue, 04/07/2020 - 06:48

2x4 Truss Bench X

I made another one and modified the angle braces on it to form an X. I made a youtube video of it here. https://youtu.be/RQriGWLUAIU

luckrish (not verified)

Thu, 04/26/2012 - 12:56

Wonderful!

I can't wait to try these! I was literally just thinking about making some benches for my dining room...and then you post these. FABULOUS!

Michelle Caudle (not verified)

Mon, 05/07/2012 - 18:18

Perfect!

I've been wanting a cute, cheap bench for my front yard and this is PERFECT! And since it's made from 2x4's (my hubby's lumber of choice) ...I can get him to build it while I finish my other building projects!!!

KaraPUK (not verified)

Tue, 05/29/2012 - 08:43

Very, very basic question.

This will be my first ever DIY project so please don't laugh at my basic question. I do not have a Kreg Jig so would be using counter sink screw method but I don't know exactly where these go on the first step? Any help would be greatly appreciated. Thanks from not so sunny Scotland!

BeckySmith

Wed, 06/06/2012 - 06:13

Help attaching cross supports

I built this bench yesterday and I am so thrilled with how it turned out. I'll post pics as soon as I get the finish on it tomorrow. The only thing I struggled with is how to attach the cross supports. It wasn't a problem so countersink the screws through the top stretcher since it is positioned horizontally but I couldn't figure out a good way to attach the cross support to the bottom stretcher. I ended up drilling through the angled part of the support from the top and into the bottom stretcher. This made sort of an unsightly screw in an odd place. I know the plans suggest using a Kreg jig, which I did for the top and legs but I don't really want the big holes created by the jig on the cross pieces since I will be staining the bench. Any suggestions?

zookeeperjay

Thu, 07/05/2012 - 17:12

1x3

I'm so excited about this bench! I saw that I could add a 1x3 for extra support I did not see where I should do that. I need the extra support any suggestions on where it goes?

zookeeperjay

Fri, 07/06/2012 - 09:39

Help please?

Does the extra support for this bench go lengthwise under the bench? I have 5 teens and one almost teen. Need that extra oomph like fish need water. All the pieces are cut and ready to go! Anxiously waiting for reply. Warmly Jay

In reply to Help please? by zookeeperjay

Lady Goats

Fri, 07/06/2012 - 09:59

1x3s

Hi Jay, I'm really not getting where the extra 1x3 would go, either, if it were me, I would build the bench as instructed, then test to see if you need the supports. It looks really sturdy to me, so you may not need the supports (trust me, I have to worry about extremely obese in laws, and I wouldn't think it would need them). If it turns out that you're worried about the structure, then add the 1x3 where it's needed.

zookeeperjay

Fri, 07/06/2012 - 10:23

Thank you LadyGoats. I'm

Thank you LadyGoats. I'm hoping to finish this today. It will be perfect for the front porch. ;o)

Alma (not verified)

Thu, 08/09/2012 - 15:22

Providence Chairs

I'd love to see some chairs to go with this collection. I made the table the other day and it is beautiful. I was hoping to figure out how to make chairs from this bench, but just can't figure out how to attach a back. Anyone else?

spiceylg

Thu, 08/23/2012 - 05:44

Providence bench angles

Hello. Can somebody please clarify, I assume you have to cut a 10 degree angle on both the top and bottom of the legs?

TxDork76

Mon, 04/01/2013 - 14:17

1x3 support and PH screws

Making this for my friends' porch. It's going well but I'm not sure about the placement for the 1x3 support either. The only place I could figure would be under the top, perpendicular to the boards. Not sure though.

I did run into a problem attaching the cross member on the legs (Step 1). I drilled 1.5" pocket holes but the 2.5" screws poked out a bit so I used 2" screws instead.

bullitt453

Mon, 05/20/2013 - 09:05

For those wondering about the 1x3 supports

Take a look at the Restoration Hardware bench that these plans are based on. TxDork76 is correct; the 1x3s go perpendicular to the 2x4 top slats.

http://www.restorationhardware.com/catalog/product/product.jsp?productI…

I plan to build this bench for my parents this week. Will definitely post the finished product.

eheinze12

Wed, 08/07/2013 - 08:32

pdf

I just wanted to ask if I can get the PDF emailed to me? It is giving me an error and I'd love to work on this asap! I am looking to give my entryway a makover:)

Ana White

Wed, 08/07/2013 - 11:32

Try this for the pdf issue

Here is a temporary solution for the PDF problems

- Go to PRINTER-FRIENDLY VERSION at the bottom of the plan;

- Copy the URL;

- Go to http://www.web2pdfconvert.com/

- Paste the URL in the window and create a PDF;

- Download the PDF to your computer and give it a proper name;

- And start building…

momofour09

Thu, 09/26/2013 - 12:23

Making larger?

I want to make the 4x4 truss table: http://ana-white.com/2013/09/plans/4x4-truss-beam-table and was wondering if this bench would work. Also if it does, what length would you recommend? Can the 45 degree pieces just be moved down to accomodate the adjusted size?

Thx

Melissa Keplinger

Sun, 07/13/2014 - 11:09

Supports

Did anybody comment on the fact that the 45 degree supports in the plans don't match the images. The images show them providing support for the middle of the table, while the plans are not providing any useful purpose, and actually will get in the way of a person's legs when they are seated.

I attached them as shown in the images because the extra stability of the middle of the table and the benches is absolutely necessary.

The plans should be updated to reflect this.

lisashortell

Tue, 12/13/2016 - 12:32

Warping?

Hello! I love this bench and have built it many times modifying it for different needs or styles.... this build I modified the top to 3 2x6's and noticed my benches starting to wobble. I took it part and my top had warped... I didn't add the cross support.... would that help stop the top from twisting? Or at 2x6's too big for the bench base? Any hep is greatly appreciated. I haven't had this issue before.... ? Thank you!!

cherokeesteve

Thu, 08/06/2020 - 16:32

Greatly appreciate the plans for this bench

Was fairly easy to make for this new to woodworking person. Came out better than expected (due to my inexperience). Stained with a light, natural looking honey pine and love how it turned out.

Bigherd

Wed, 01/13/2021 - 07:54

2X4 Truss Style farmhouse bench.

I made two of these. Both were 48" long and 18" tall. One was 12" deep and the other 15" One bench seat was made up of 4 2x4s while the 15" bench seat was made using three 2x6's. I used my jointer flatten the edge and face of the lumber. then i used my thickness plainer to get the width i needed. I had about $30 in each bench and ended up selling each one for $100. I enjoyed making this bench.

woodworkHER

Wed, 04/28/2021 - 12:41

Awesome!

I loved making this bench, it was my first project following wood plans. I want to make an outdoor sofa, but considering the price of lumber I wanted a cheaper project to try out first. Your plans are wonderful, I only wish there were screw locations included with the plans like others I’ve seen.