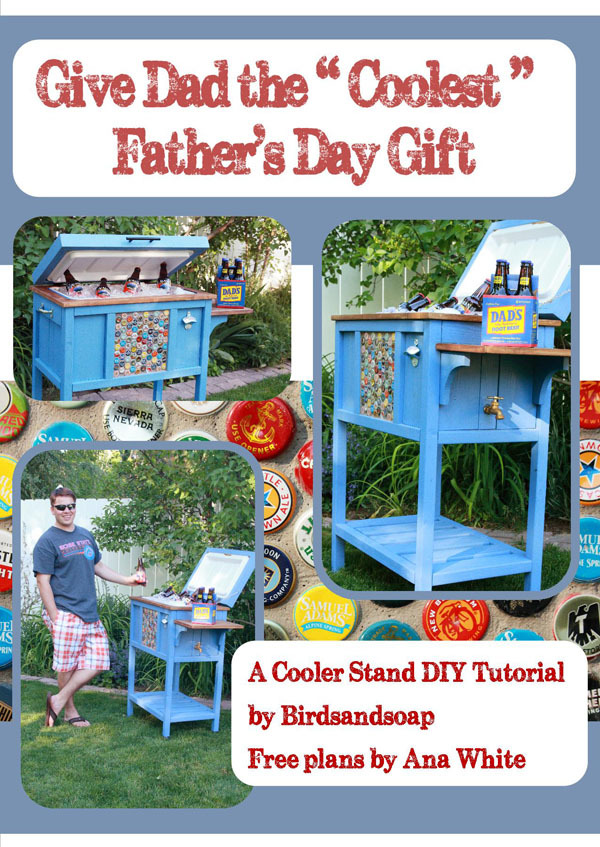

DIY wood cooler plans!

Preparation

Cooler (designed to fit this one)

4 - 2x2 @ 8 feet long

3 - 1x3 @ 8 feet long

2 - 1x6 @ 8 feet long

2 - 2x4 @ 8 feet long

1 - 1x2 @ 8 feet long

Hinges, caster wheels if desired

MAIN COOLER

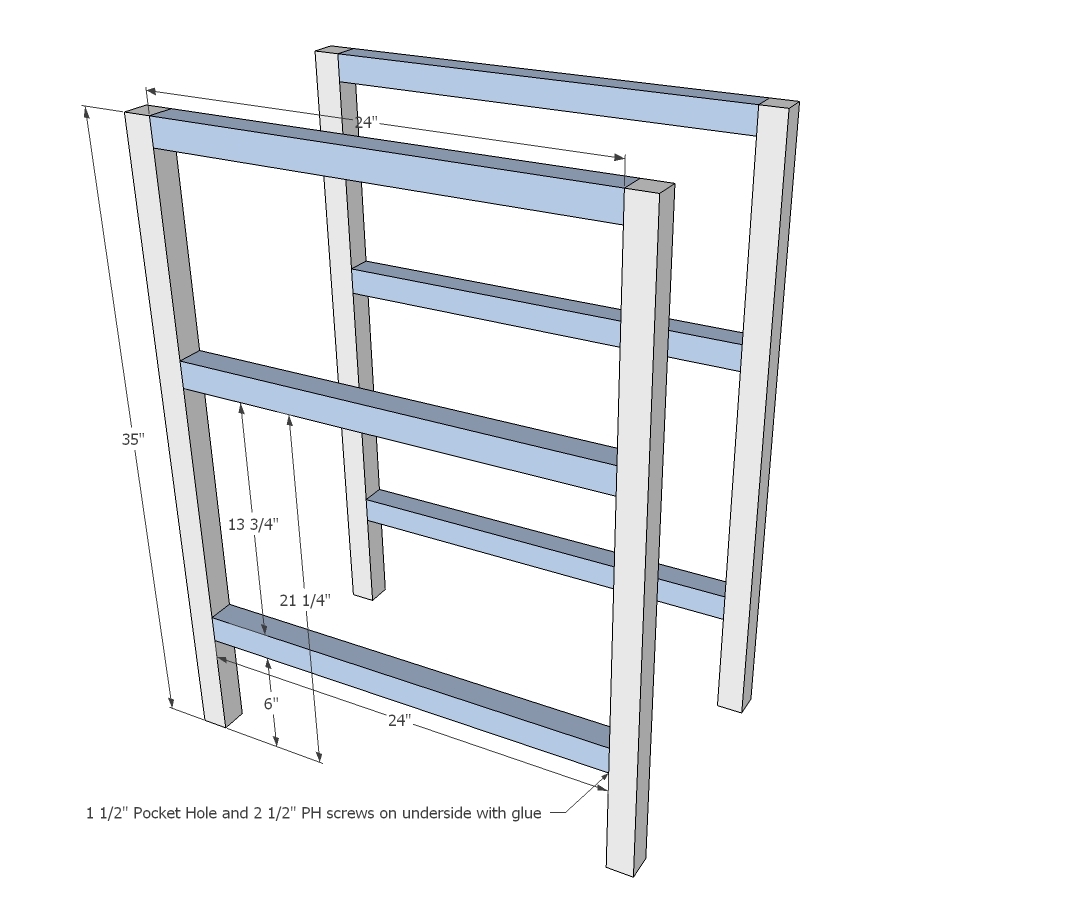

4 - 2x2 @ 35" (legs)

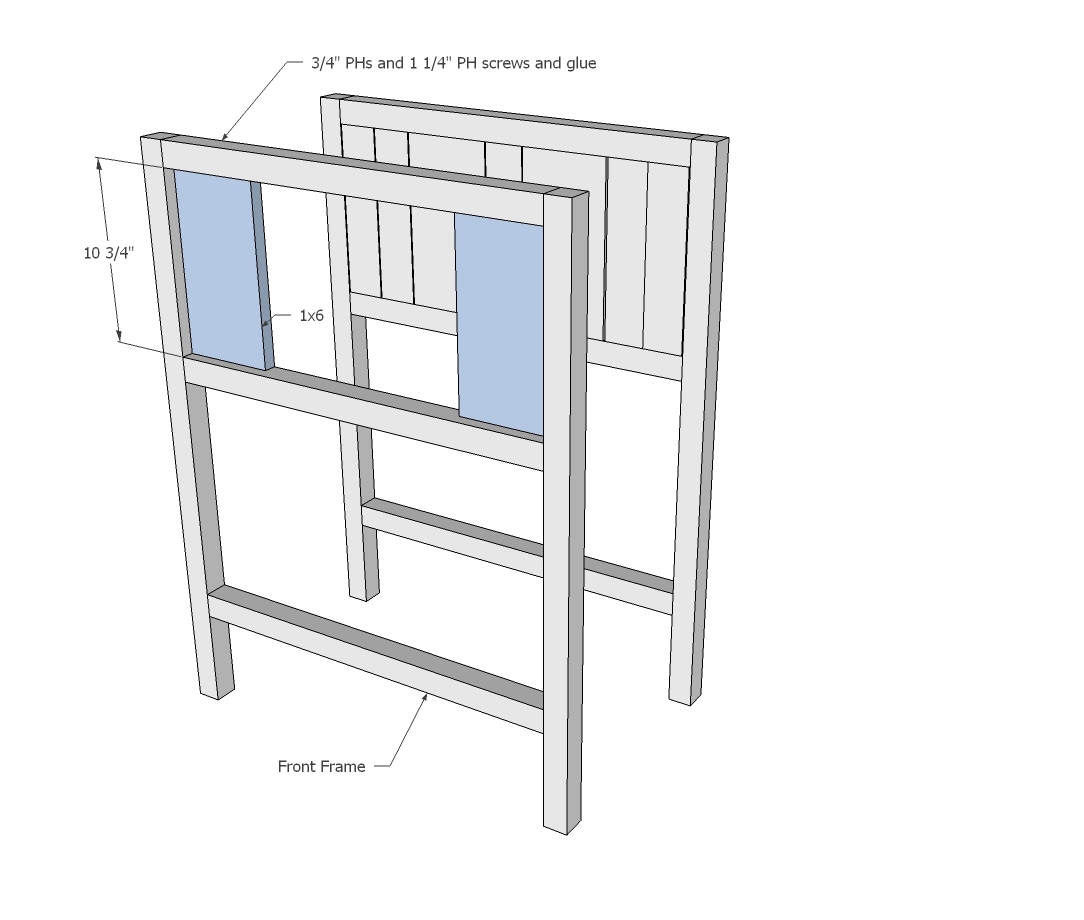

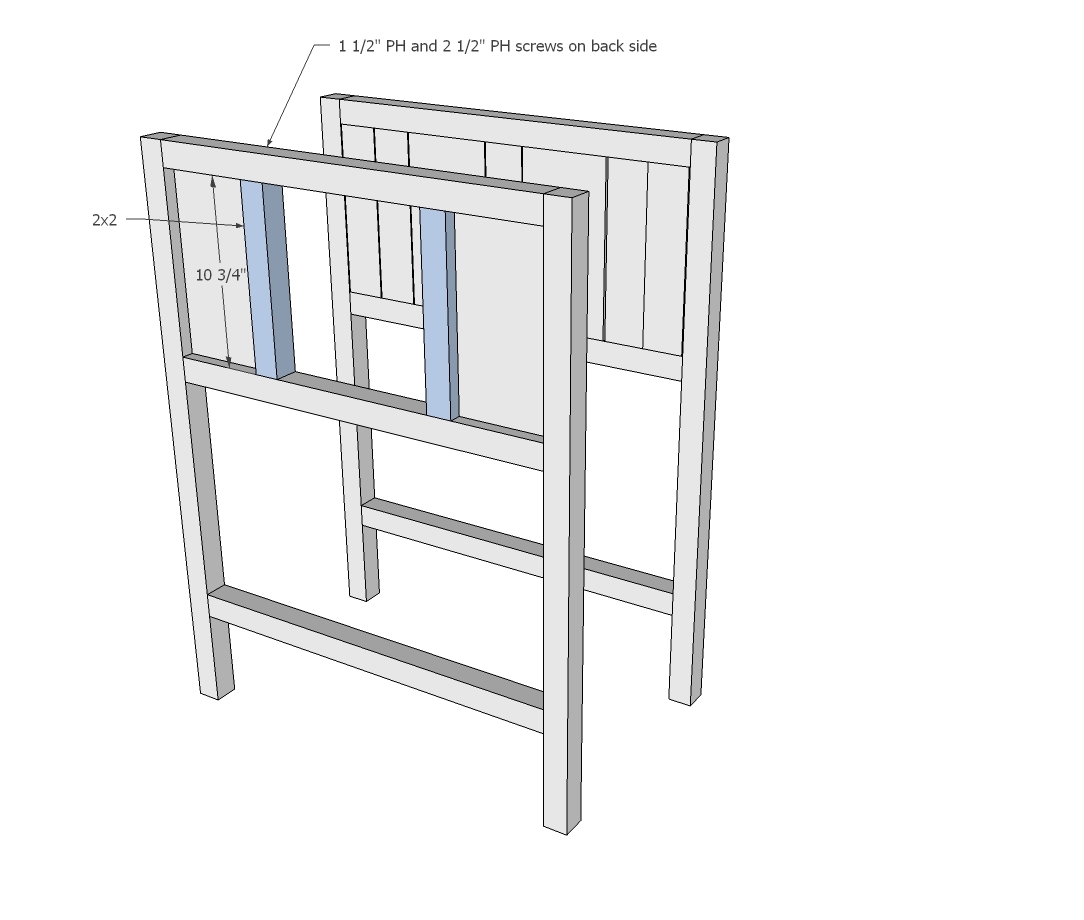

6 - 2x2 @ 24" (frame for front/back)

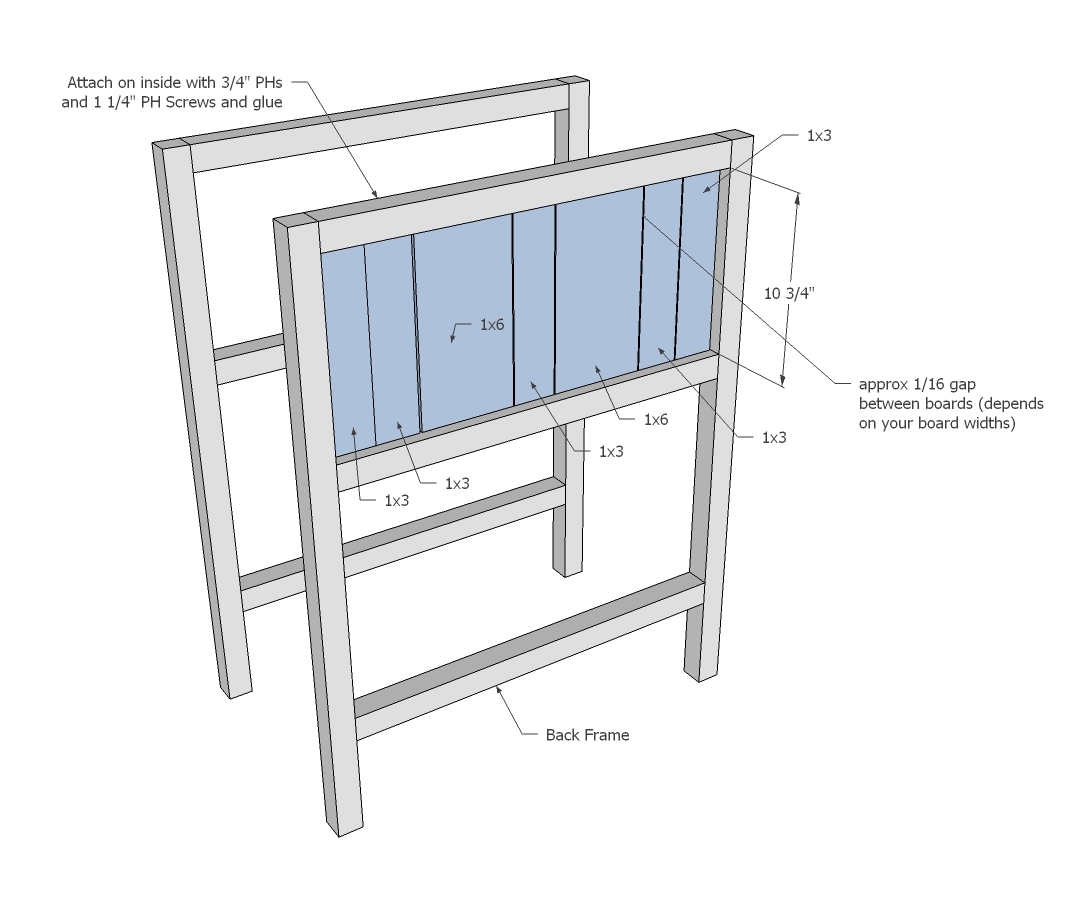

5 - 1x3 @ 10 3/4" (back panel boards)

4 - 1x6 @ 10 3/4" (front and back panel boards)

2 - 2x2 @ 10 3/4" (front panel boards)

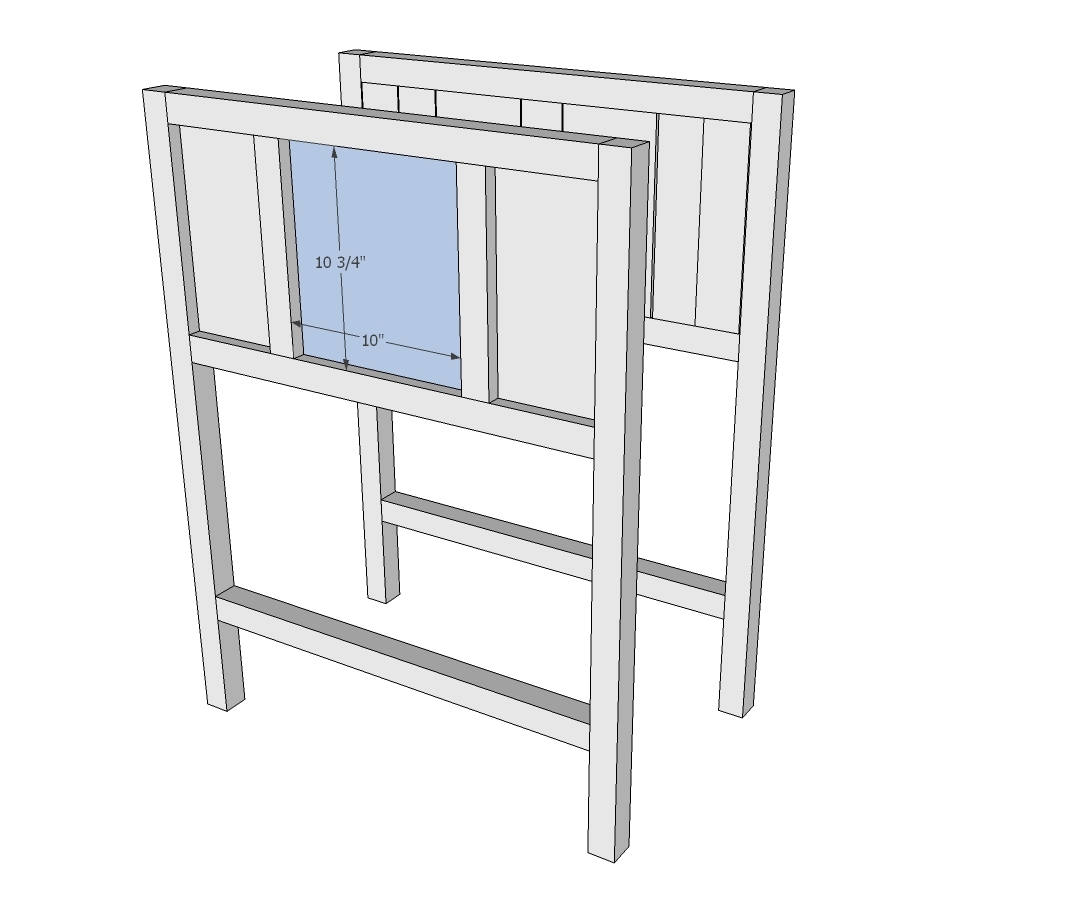

Scrap plywood 10 3/4" x 10"

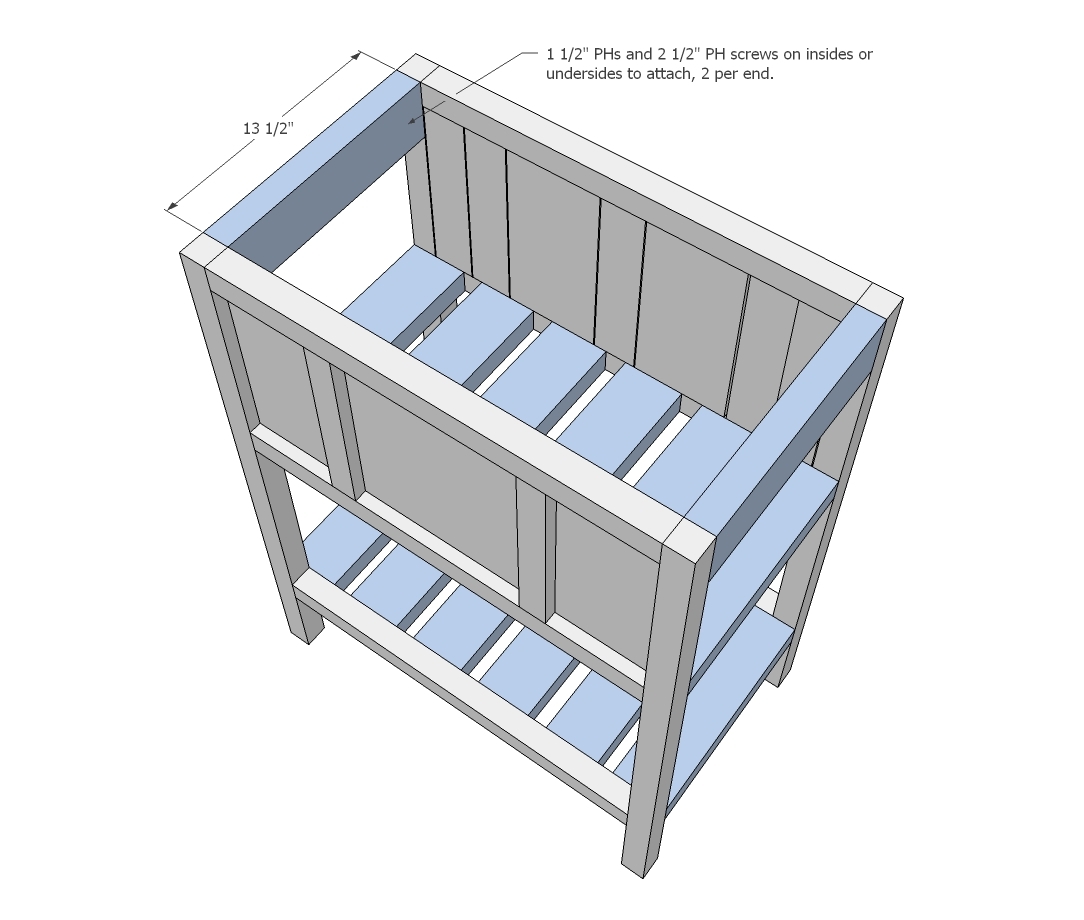

14 - 2x4 @ 13 1/2" (sides and shelf slats)

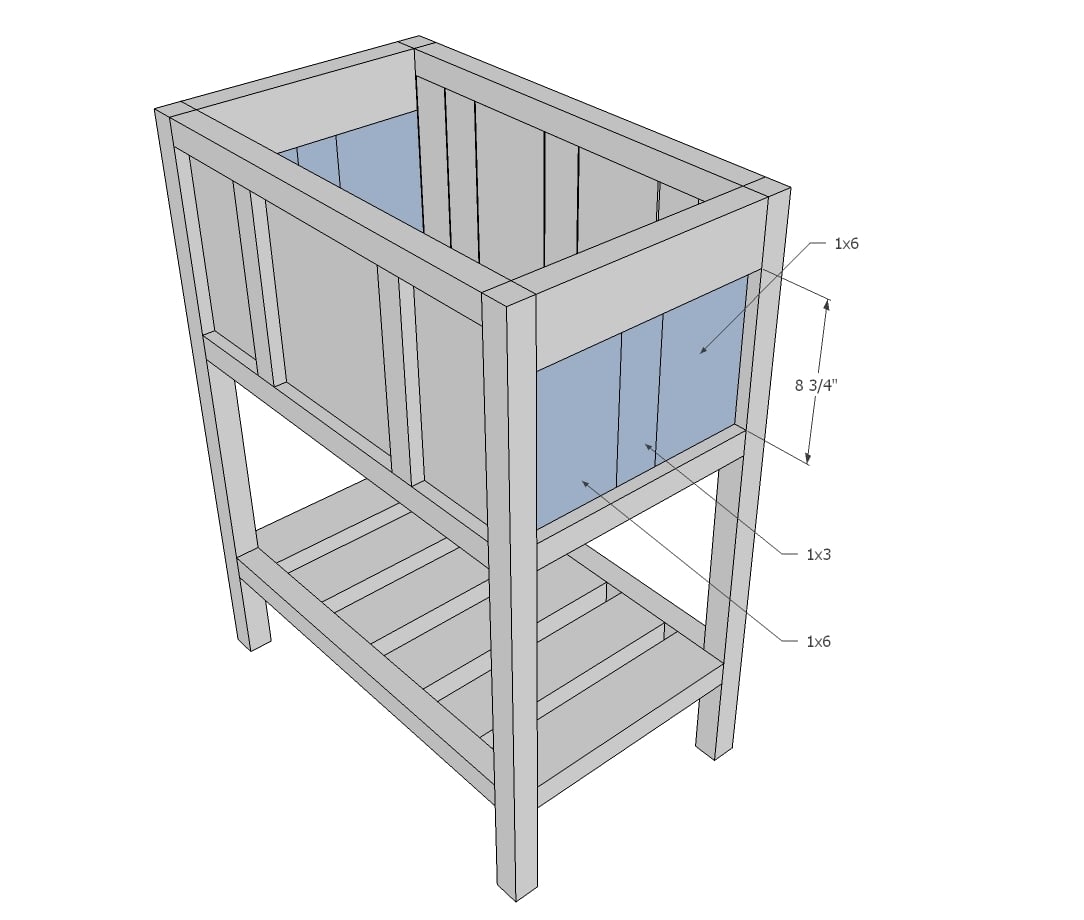

4 - 1x6 @ 8 3/4" (Side panels)

2 - 1x3 @ 8 3/4" (side panels)

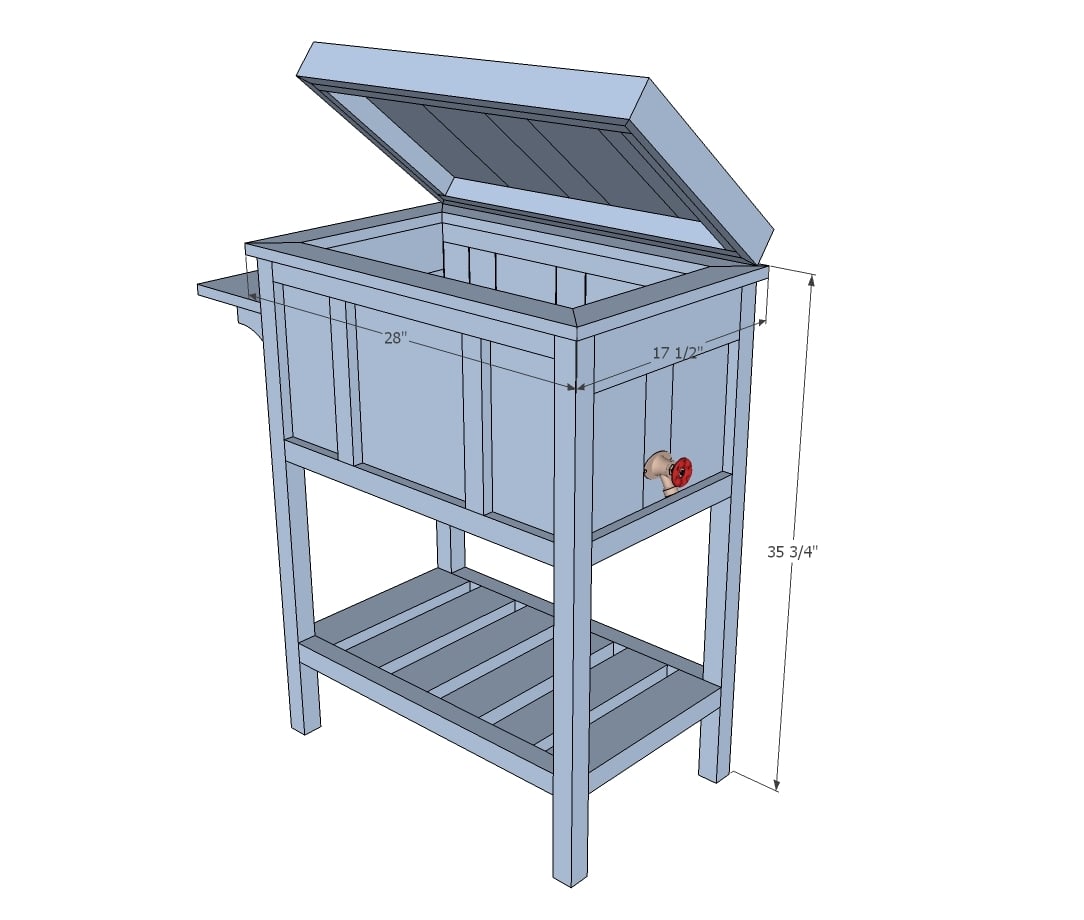

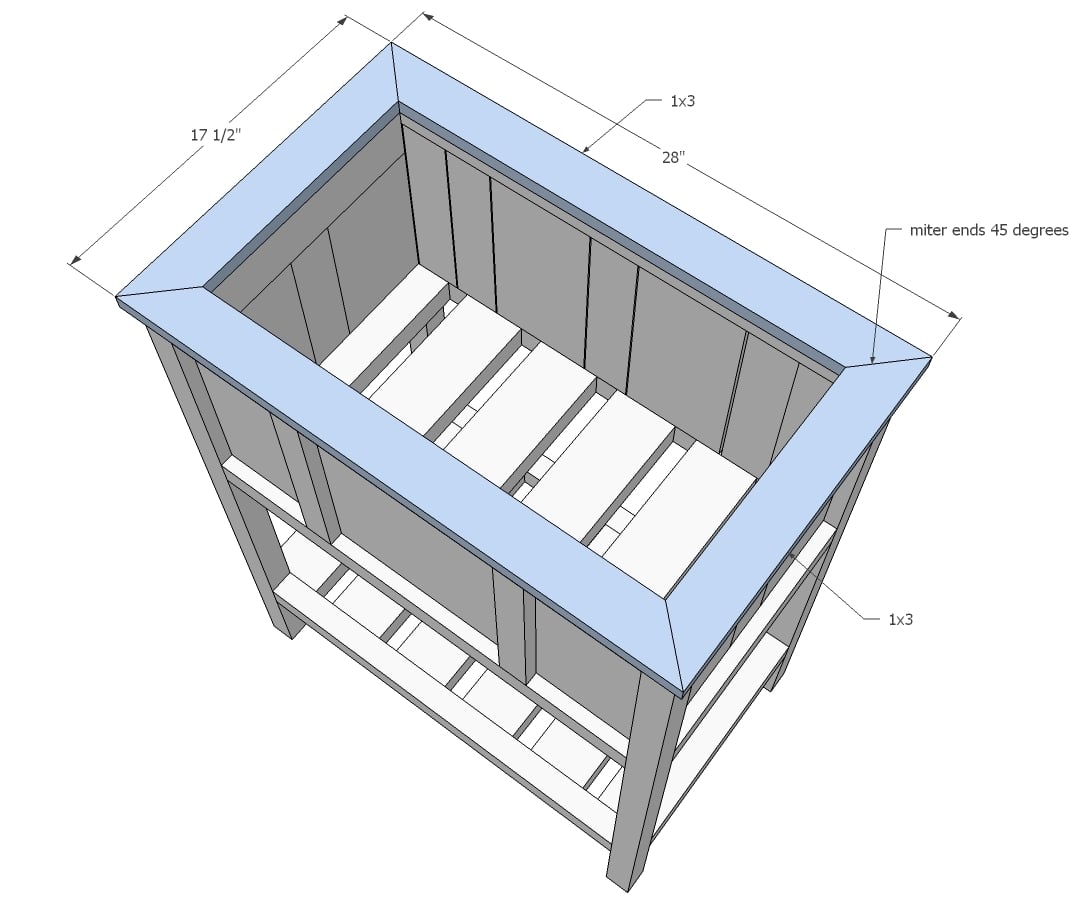

2 - 1x3 @ 28" - both ends mitered at 45 degrees NOT parallel, long point measurement (top frame)

2 - 1x3 @ 17 1/2" - both ends mitered at 45 degrees NOT parallel, long point measurement (top frame)

LID

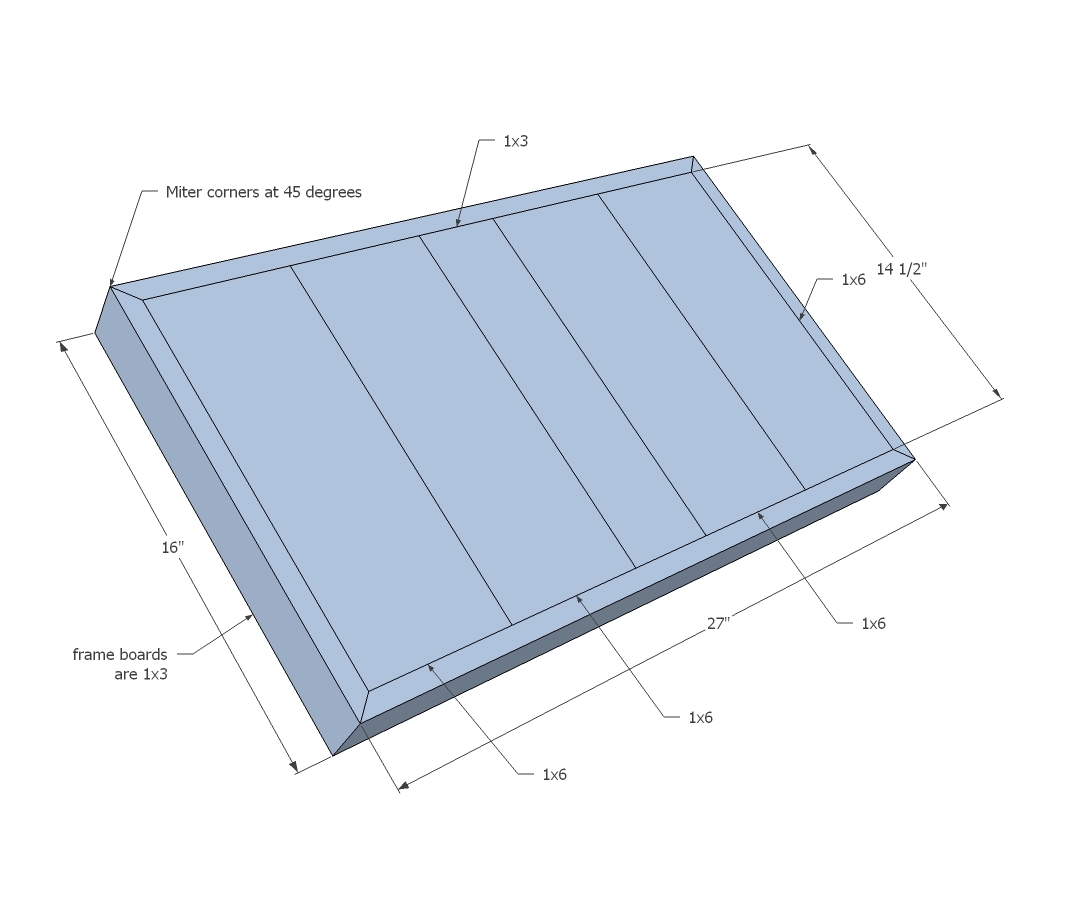

2 - 1x3 @ 27" - both ends beveled at 45 degrees NOT parallel, long point measurement (top frame)

2 - 1x3 @ 16" - both ends beveled at 45 degrees NOT parallel, long point measurement (top frame)

4 - 1x6 @ 14 1/2" (top panel)

1 - 1x3 @ 14 1/2" (top panel)

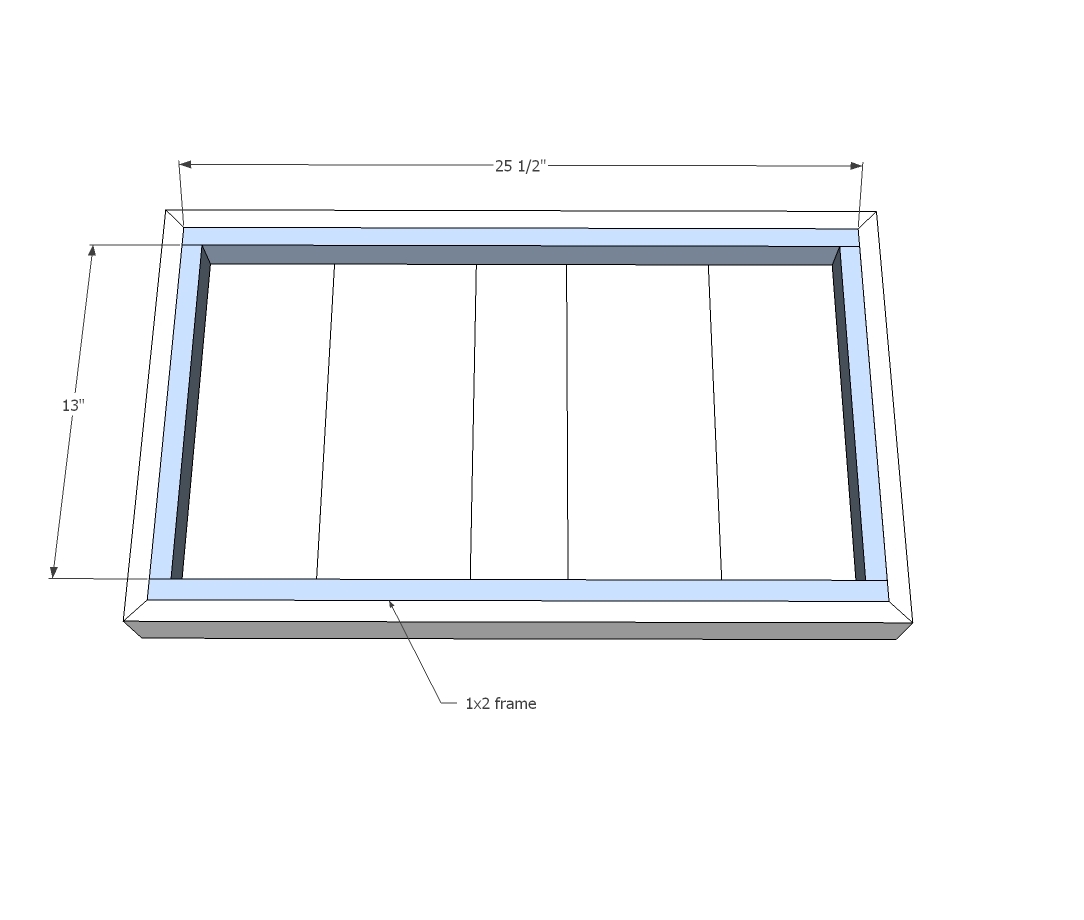

2 - 1x2 @ 13" (inner frame)

2 - 1x2 @ 25 1/2" (inner frame)

SHELF

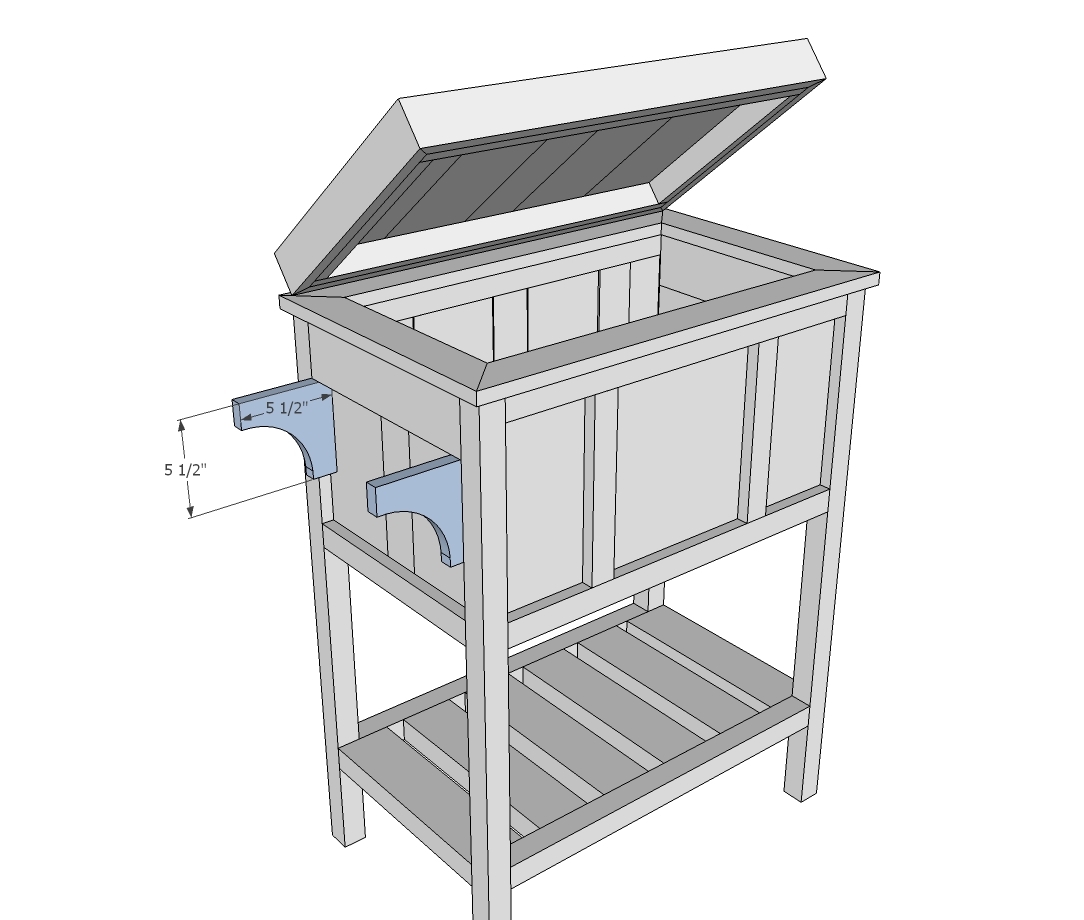

2 - 1x6 @ 5 1/2" - cut out arch shape (supports)

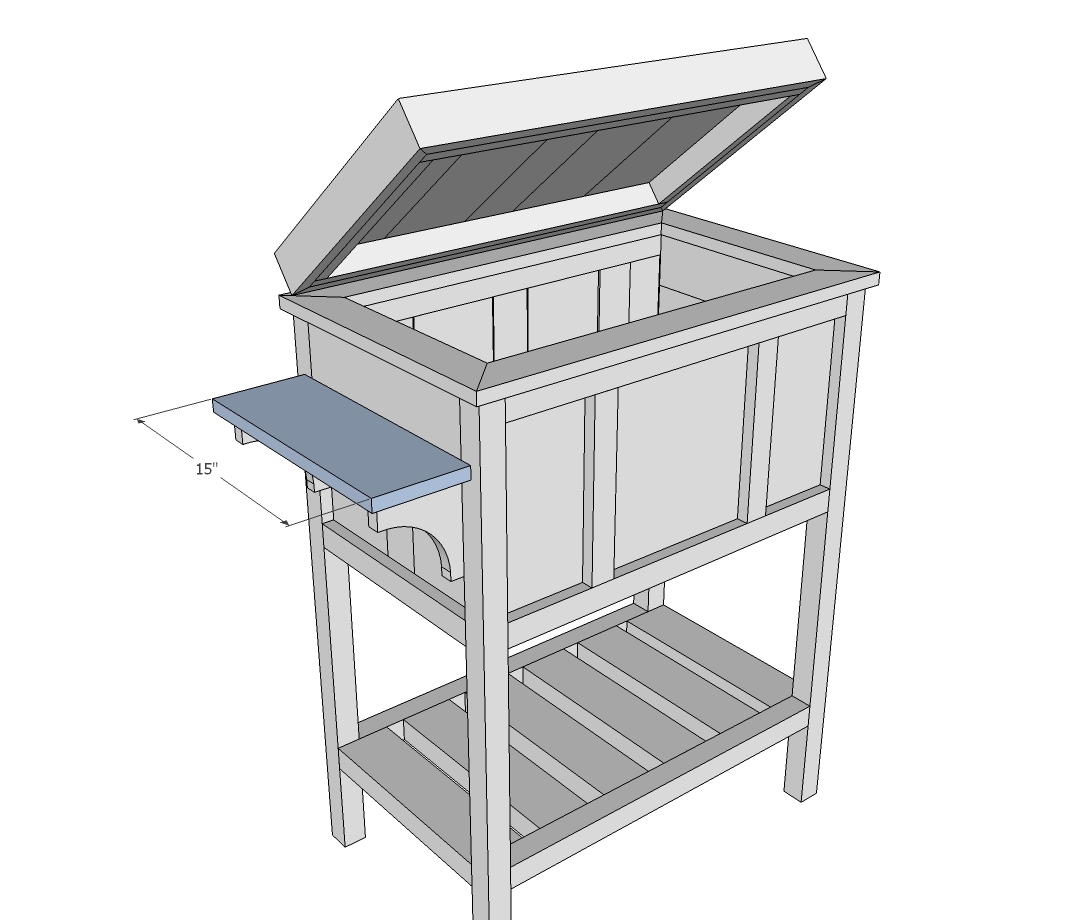

1 - 1x6 @ 15" (shelf)

Please read through the entire plan and all comments before beginning this project. It is also advisable to review the Getting Started Section. Take all necessary precautions to build safely and smartly. Work on a clean level surface, free of imperfections or debris. Always use straight boards. Check for square after each step. Always predrill holes before attaching with screws. Use glue with finish nails for a stronger hold. Wipe excess glue off bare wood for stained projects, as dried glue will not take stain. Be safe, have fun, and ask for help if you need it. Good luck!

Instructions

Step 2

Step 3

Step 8

Step 10

And then add the inner frame to keep the lid in place.

Step 11

Step 12

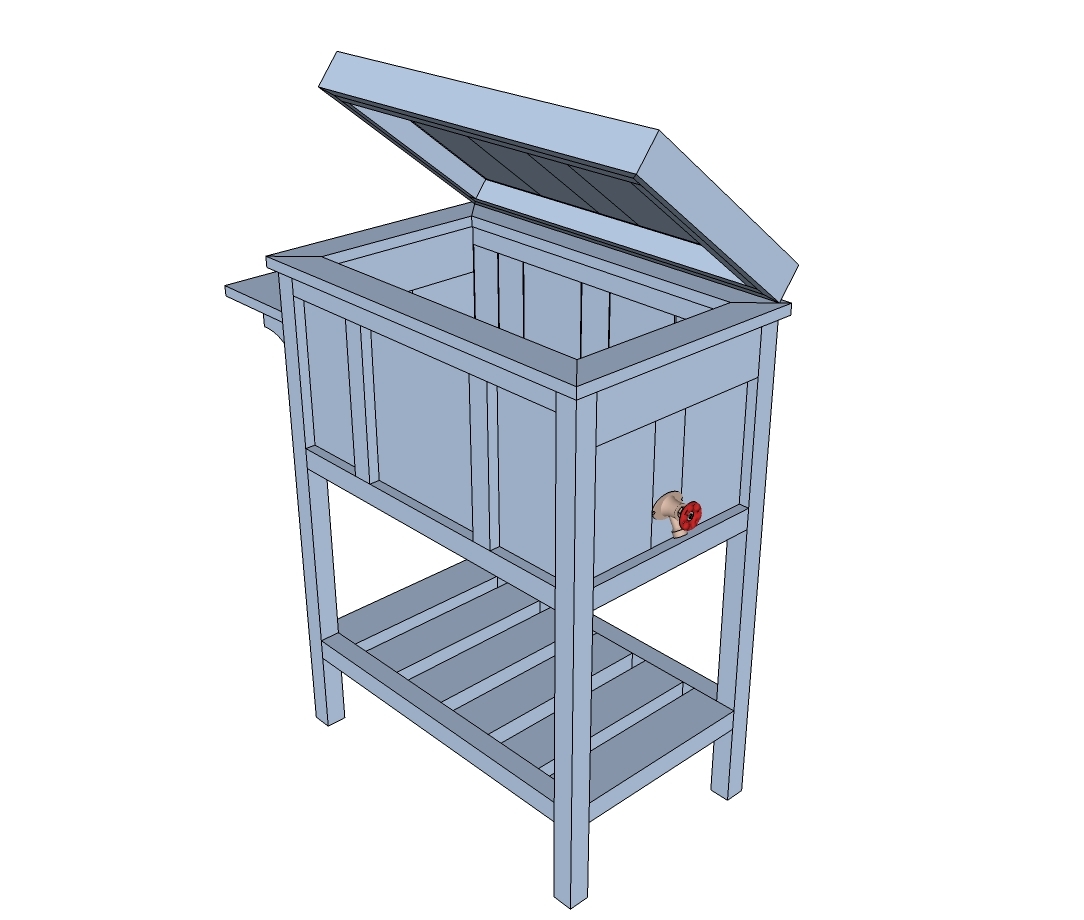

And the shelf on top. I simplified in the plans with the 1x6 shelf - I love how Jenny made her shelf here.

Step 13

For more details on attaching the drain to the cooler - please read through Jenny's post as well.

It is always recommended to apply a test coat on a hidden area or scrap piece to ensure color evenness and adhesion. Use primer or wood conditioner as needed.

Comments

spiceylg

Tue, 06/11/2013 - 05:55

Cool

Very cool indeed! Nice job!

Chexmix09

Wed, 06/12/2013 - 05:09

bottle caps

What is it that you are putting the bottle caps in?? Is that some kind of putty?

In reply to bottle caps by Chexmix09

birdsandsoap

Wed, 06/12/2013 - 21:13

The caps were glued onto a

The caps were glued onto a 3/4" plywood base, then grouted with a sanded tile grout.

Pharmdrxt

Tue, 05/18/2021 - 12:42

plans

are these plans still available

countrysideworkshop

Sat, 07/27/2013 - 19:48

HELP

I am trying to build mine, but on the first picture in the plan with the front and back legs there is a missing measurement. The overall length. The middle supports measure at 24" but the overall including the legs is what? I ask because I added 1.5" per leg (milled 2x2 size) to the 24" which would give it an overall 27". But then if you had the 1" for the top lip that is built later in the plan than the lip is one inch off all the way around. But the plan says the lip is 28"x17.5"

countrysideworkshop

Sun, 07/28/2013 - 12:26

Measurements Off, Maybe?

Are the plans made with milled dimension sizes? The lid isn't adding up. The panels (4 1x6 & 1 1x3 milled = 24.5"). If you create a frame that is 27x16 then it will be one inch to long. But if you used unmilled sizes then the frame would be 1 inch to short.

In reply to Measurements Off, Maybe? by countrysideworkshop

CSaintD

Sun, 01/26/2014 - 10:21

countrysideworkshop - 27" is

countrysideworkshop - 27" is the outside measurement of the frame. If you take off the 1.5" for each 2x2 leg (the panels go inside), then you get 24" to fill in for the panels. I ended up using 3 1x3's and 3 1x6's for the back panel - this fits exactly into the 24" frame.

kmkoncir

Thu, 04/28/2016 - 07:45

Same issue - help?

Hey countrysideworkshop. I'm having the same issue? What measurements did you use to correct the lid problem? Advice from anyone would be much appreciated!

CSaintD

Sun, 01/26/2014 - 10:09

help for building

Hi, I am building this right now and have a question about the panels. The plan says to use pocket holes and screws to attach the panels to the frame. Do I attach the panel pieces together first, or just screw them into the head and foot rails of the frame? I am concerned about the outside panels hitting the screws that I used to build the frame (from 2x2 to 2x2), also with the outside 2x4's intersecting the screws from the frame.

Thanks in advance. This is the first time I've built anything like this and so want to be sure of everything before I make a mistake.

ashleymdahl

Thu, 02/22/2018 - 00:23

Lid size seems off?

The width of the lid is the same as the base but the depth is 1/2 an inch smaller...is this an error in the plan or is it meant to be this way? It looks a bit "off" to me.

RHgaijin2

Sun, 04/14/2019 - 20:10

Wood Cooler

I made a video of the pictures I took while making this cooler. https://youtu.be/VfVbId3FeU4