Build your own round modern dining table with free plans from Ana-White.com

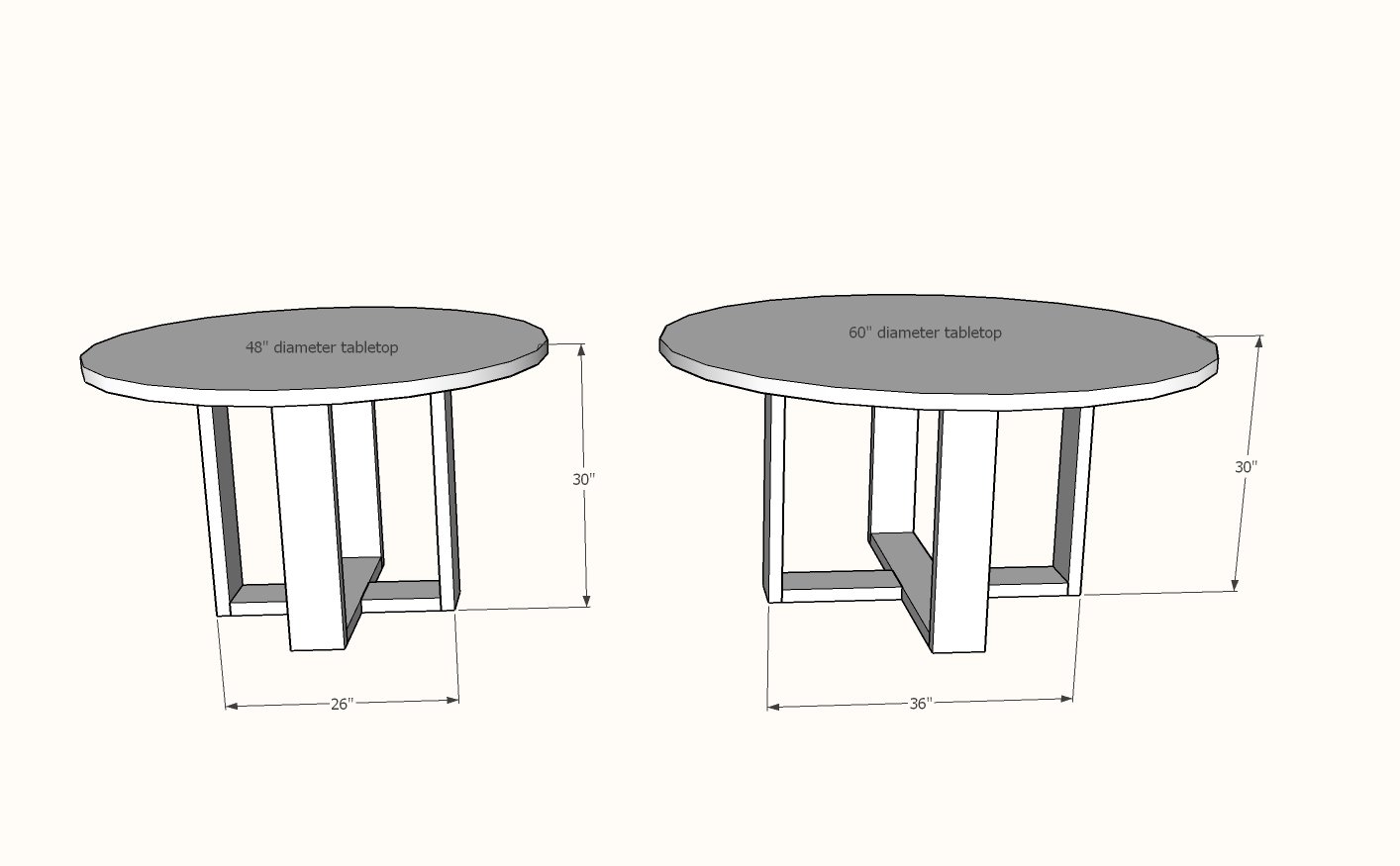

Dimensions

Dimensions for 48" and 60" tables

Preparation

Shopping List

For 48" Base

- 2 - 2x6 @ 8 feet or stud length

- 24 - 2-1/2" pocket hole screws

For 60" Base

- 2 - 2x6 @ 10 feet or stud length

- 24 - 2-1/2" pocket hole screws

Divide the cuts evenly between the two boards.

You will also need screws for attaching the tabletop. If your tabletop is 1-1/2" thick you can use the 2-1/2" pocket hole screws.

Cut List

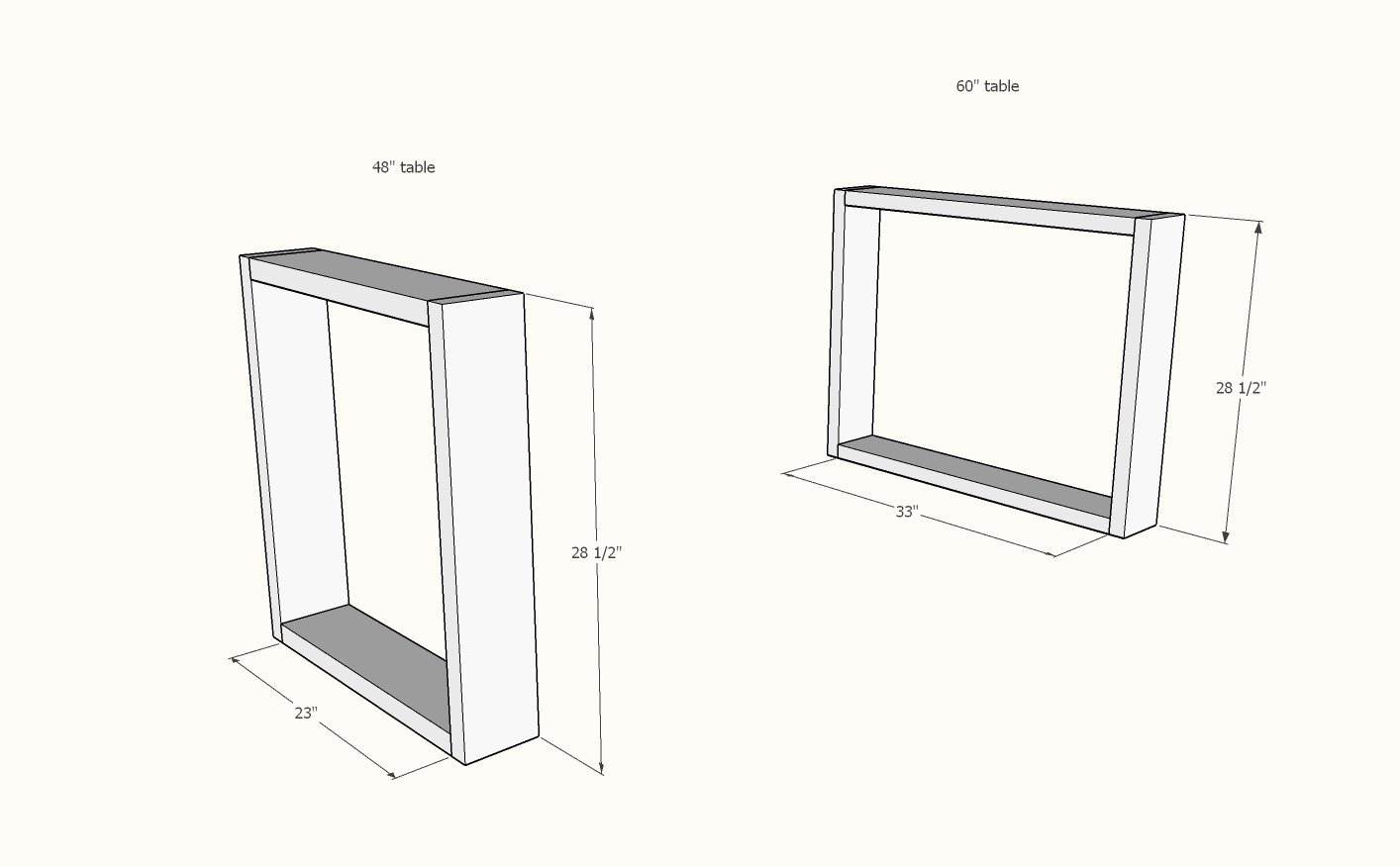

Cut List for 48" Table Base

- 4 - 2x6 @ 28-1/2"

- 2 - 2x6 @ 23"

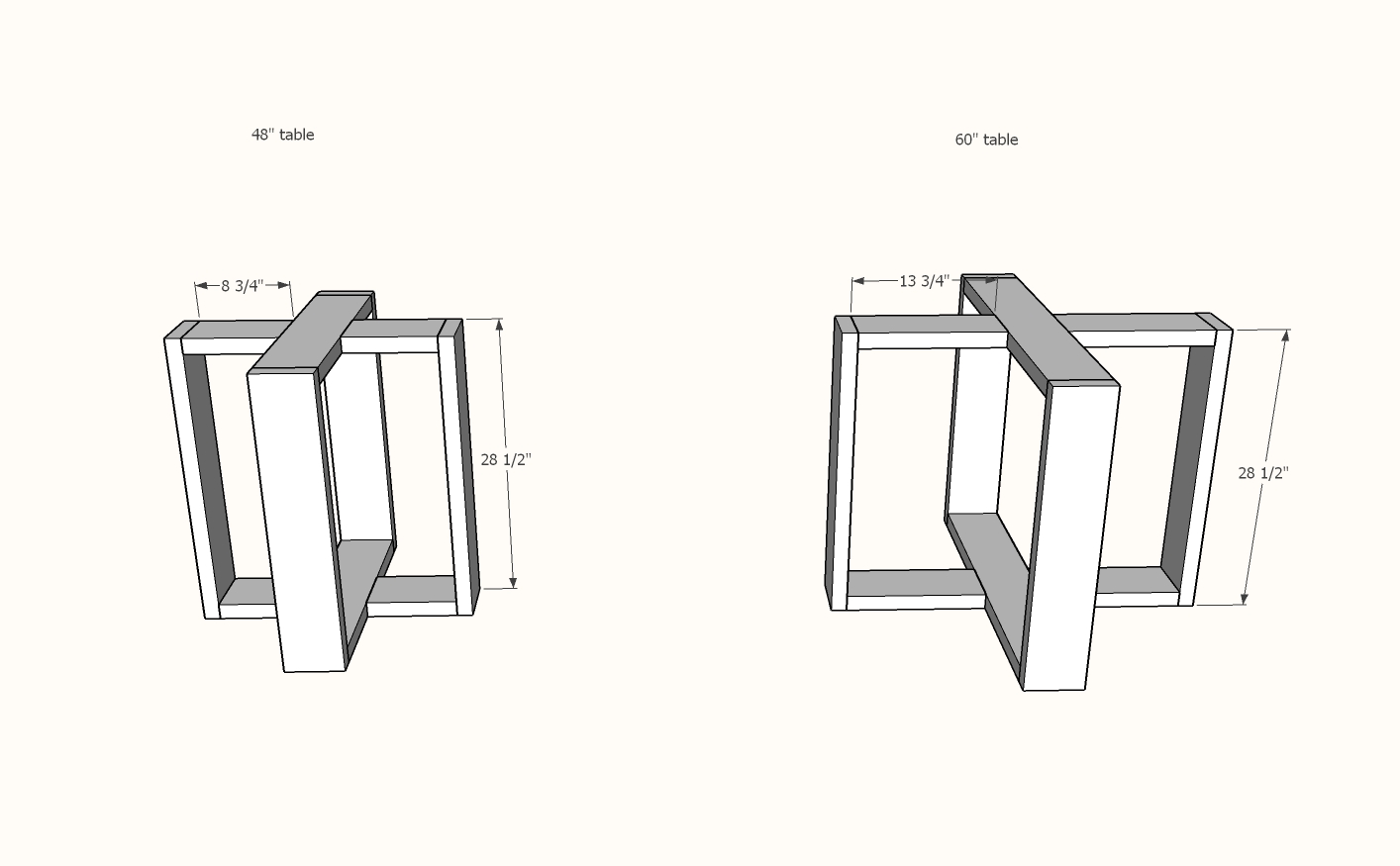

- 4 - 2x6 @ 8-3/4"

Cut List for 60" Table Base

- 4 - 2x6 @ 28-1/2"

- 2 - 2x6 @ 34" *

- 4 - 2x6 @ 14-1/4" *

*I added one inches to the 60" table base from the diagrams, because I felt like it needed to be slightly larger to reduce potential tipping.

General Instructions

I recommend presanding all the boards first.

Carefully cut out the 2x6 boards on the compound miter saw.

Drill two 1-1/2" pocket holes on both ends of every board except for the four leg boards (28-1/2" length).

Instructions

Step 1

Step 2

Project Type

Room

Comments

mferrante

Tue, 03/24/2020 - 15:42

I love the modern simplicity…

I love the modern simplicity of this table base! Looking for an outdoor rectangular table with this base version that could accommodate 10-12 people 🙌🏻

Anzura

Mon, 10/05/2020 - 19:40

A few errors, but a really cool modern base

Went hunting table bases for my glass round at all the usual stores and online. Everything is crazy expensive! Made this for $50 and it turned out great! Will put clear rubber bumpers on top for the glass to sit on.

Cut list for the 48" base adds up to more than 16'. I took off 1/2" from all cuts except legs. Also, I suggest adding the smaller pieces to the first rectangle before you attach second set of legs or else you won't be able to get drill in to pocket holes. That will make sense when you see it in person.

ileneshopper

Mon, 02/01/2021 - 05:18

Hi, I finished this table…

Hi, I finished this table base yesterday and I absolutely love it. This is the first time I’ve ever made anything like it on my own. I have a traditional table now that I want to take apart and repaint so I can use the old top with the new base. Can you explain how to attach the old top to the new modern base. Please be basic :)... this is all new to me. Thanks!!