Free plans for round table top building in sizes from 24" to 72"

I love round tables - they are so comfortable, sensible, and beautiful! But making the round table tops do take a little more figuring than a rectangle or square shape - so I took the time to create patterns for round table tops in sizes 24", 30", 42", 48", 54", 60" and 72" and am sharing my round table top patterns and plans for free in this post!

The patterns include diagrams for each size, step by step instruction, and even a video tutorial. I use a circular saw and homemade jig to cut the round shape - in this video I show how.

Pin For Later!

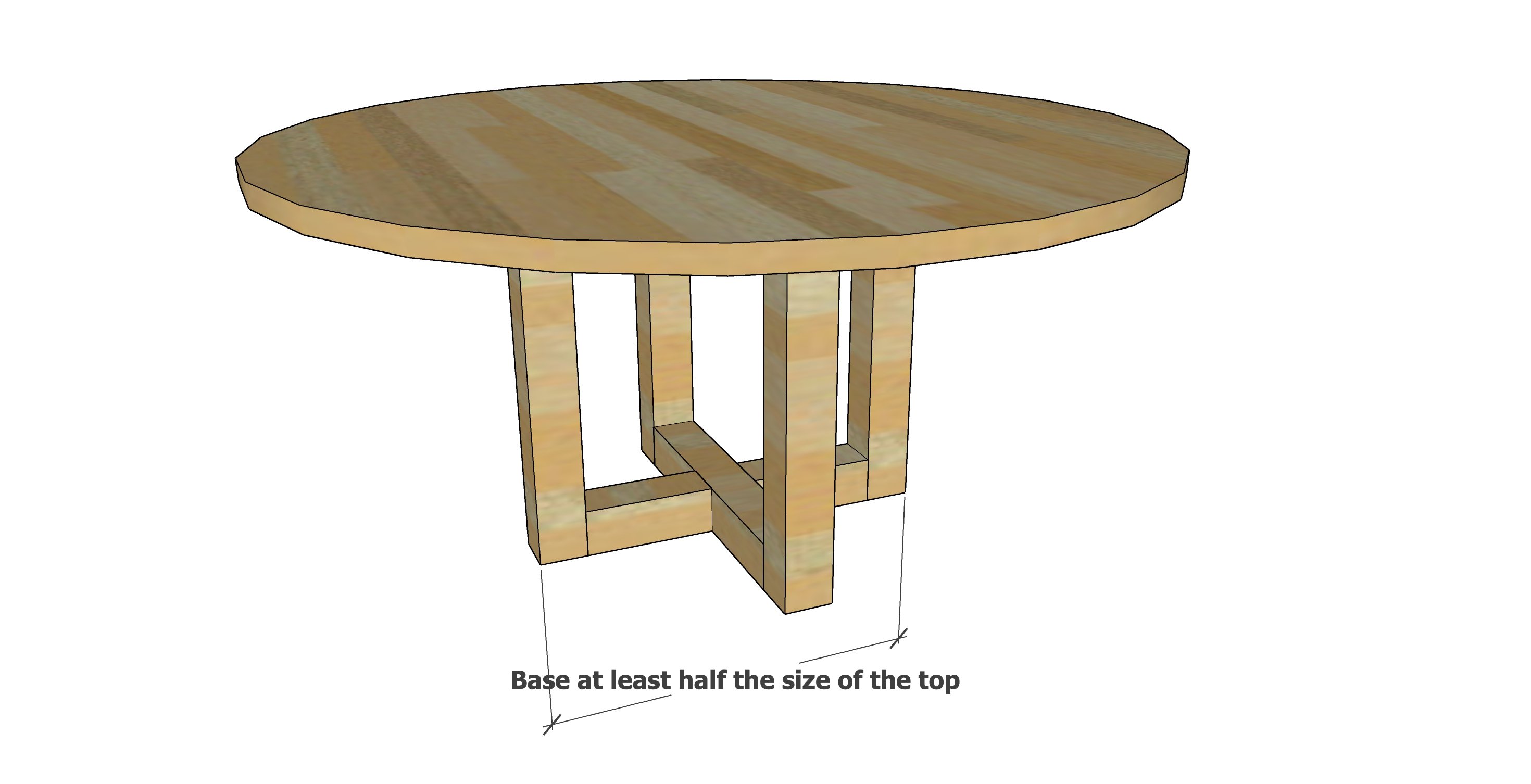

Preparation

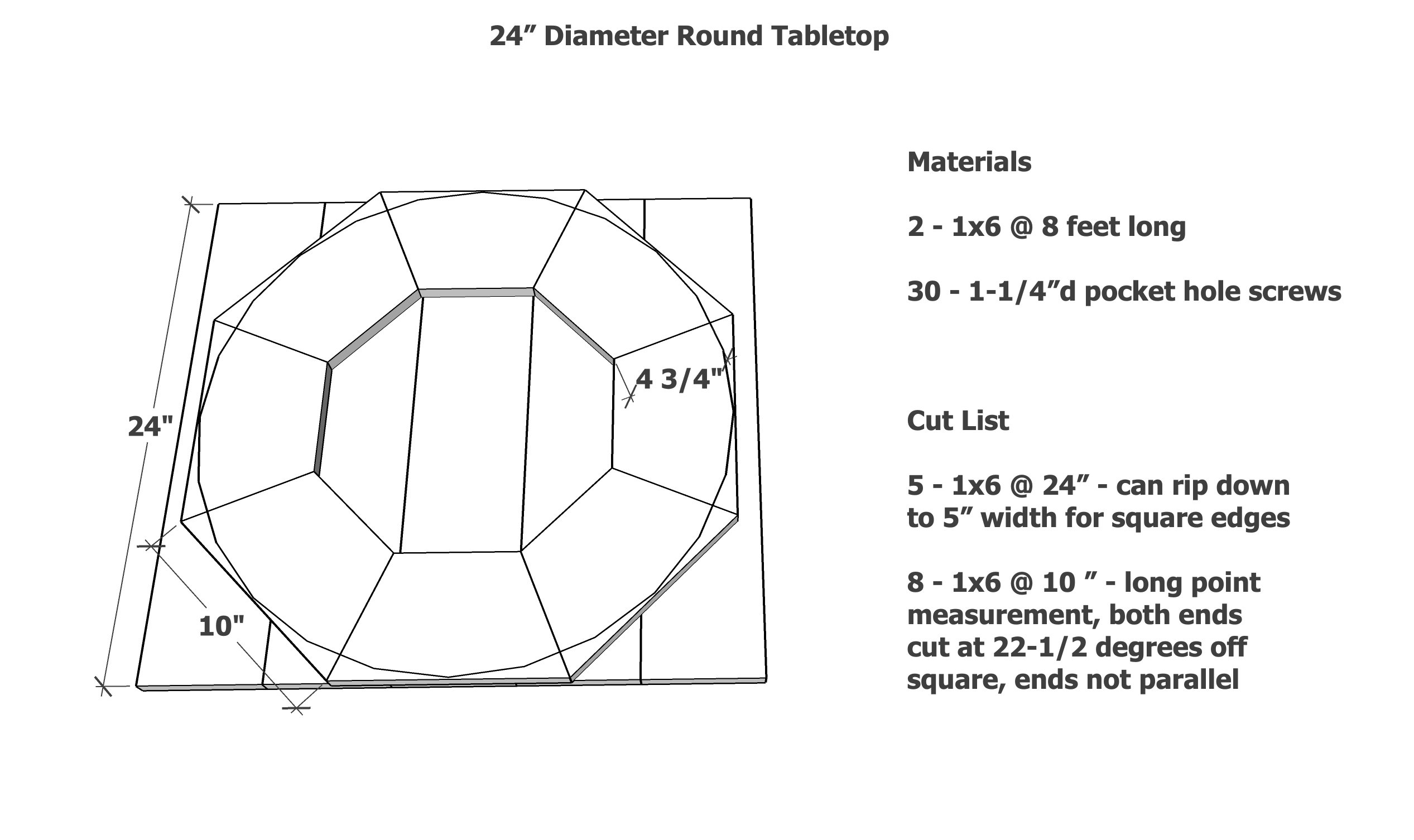

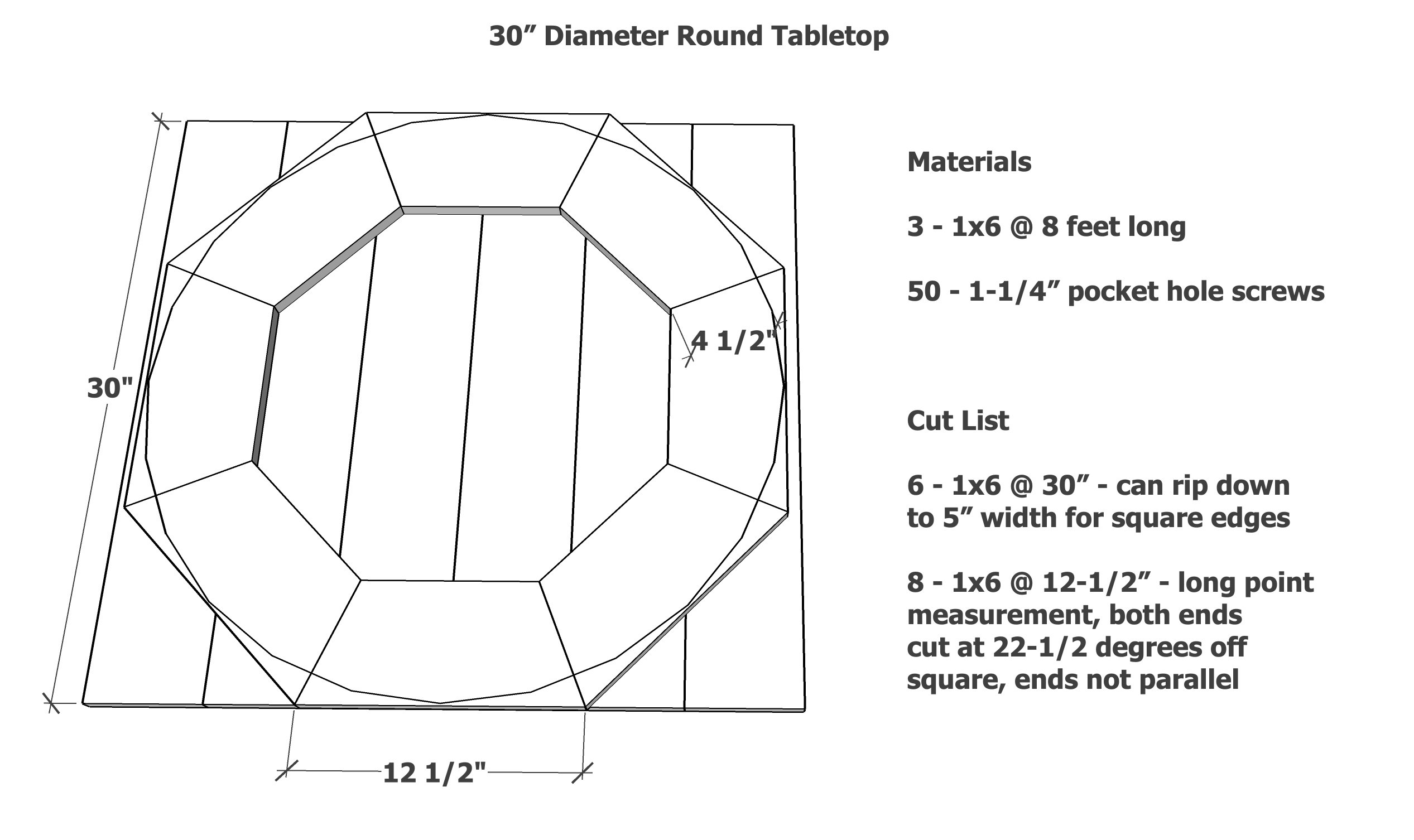

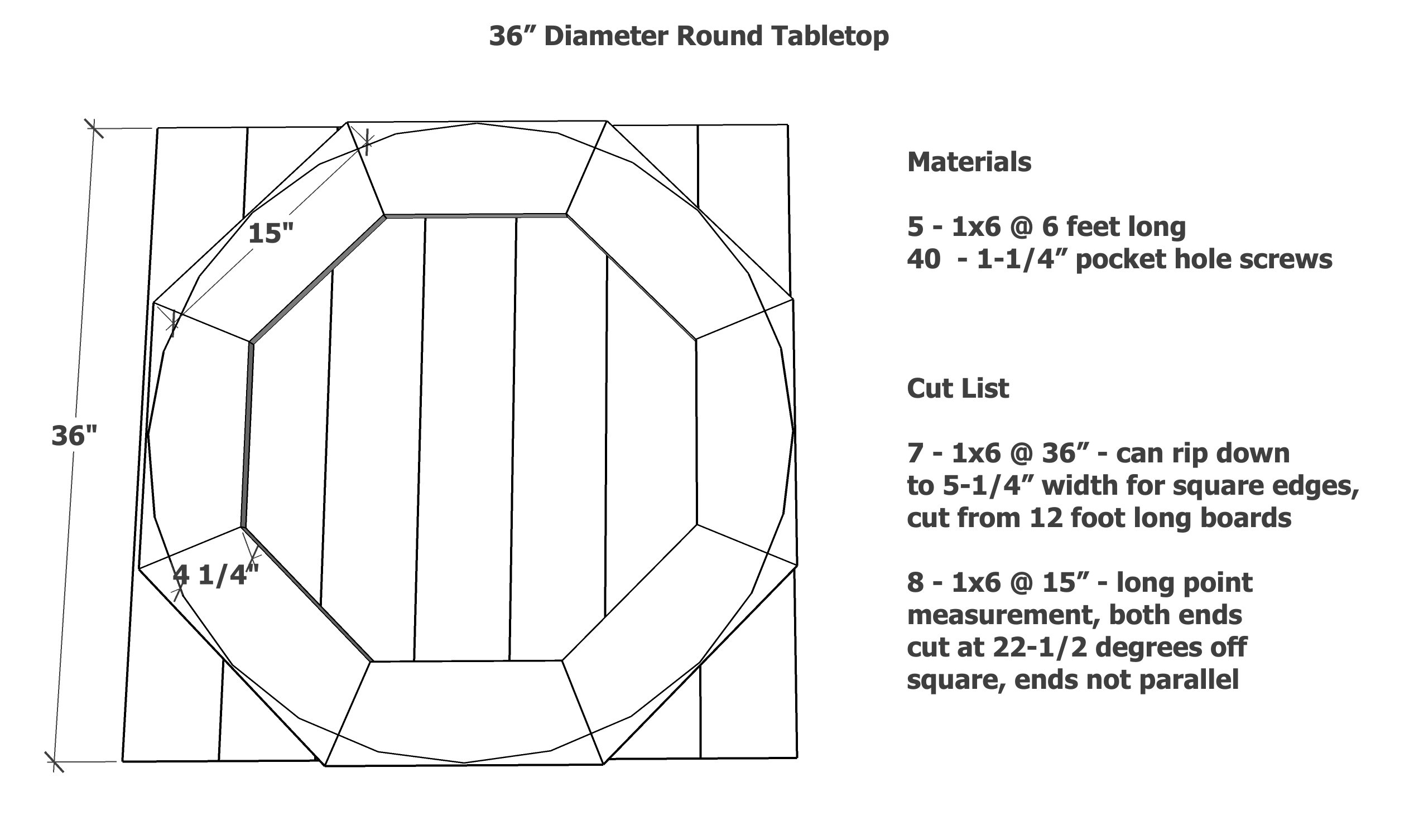

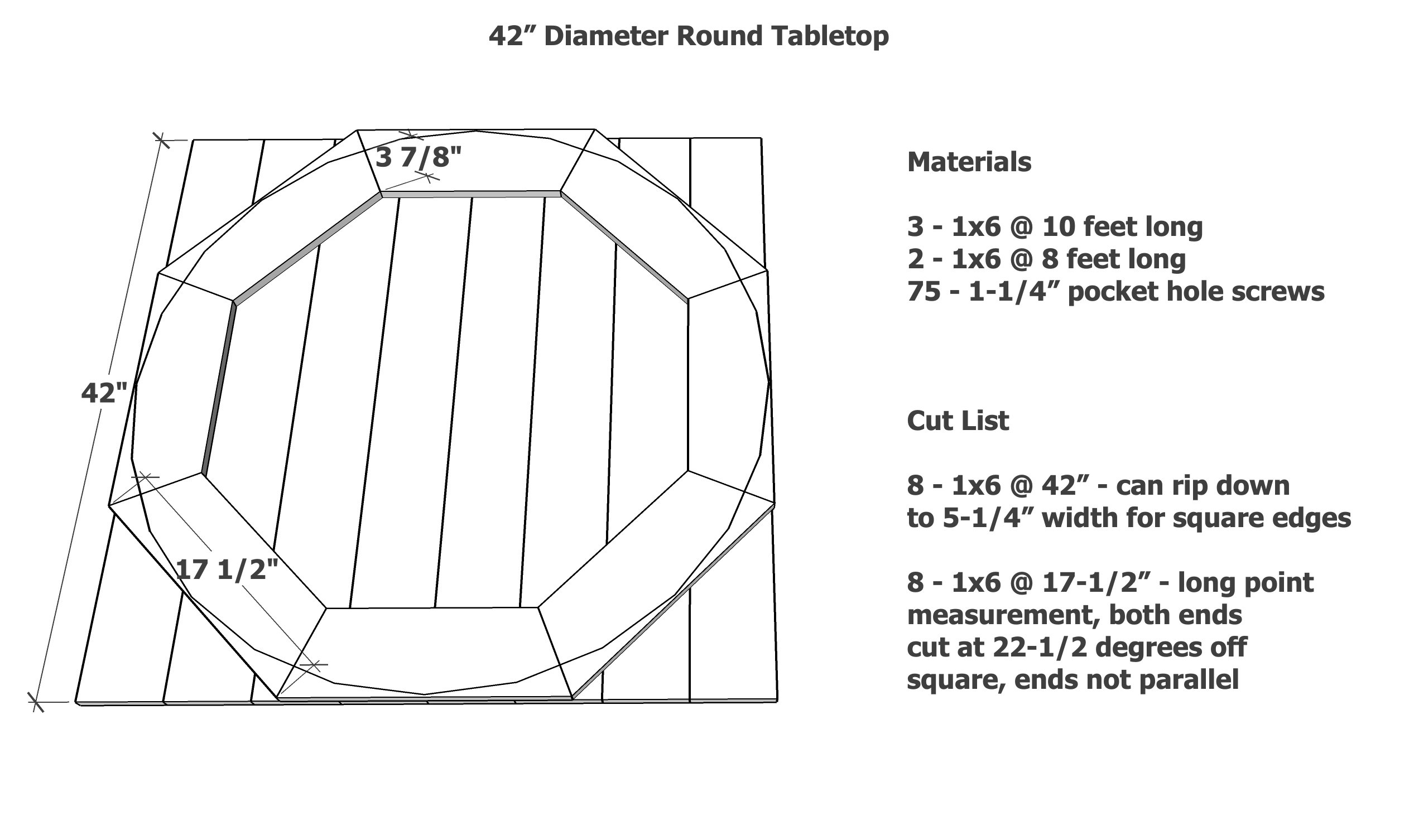

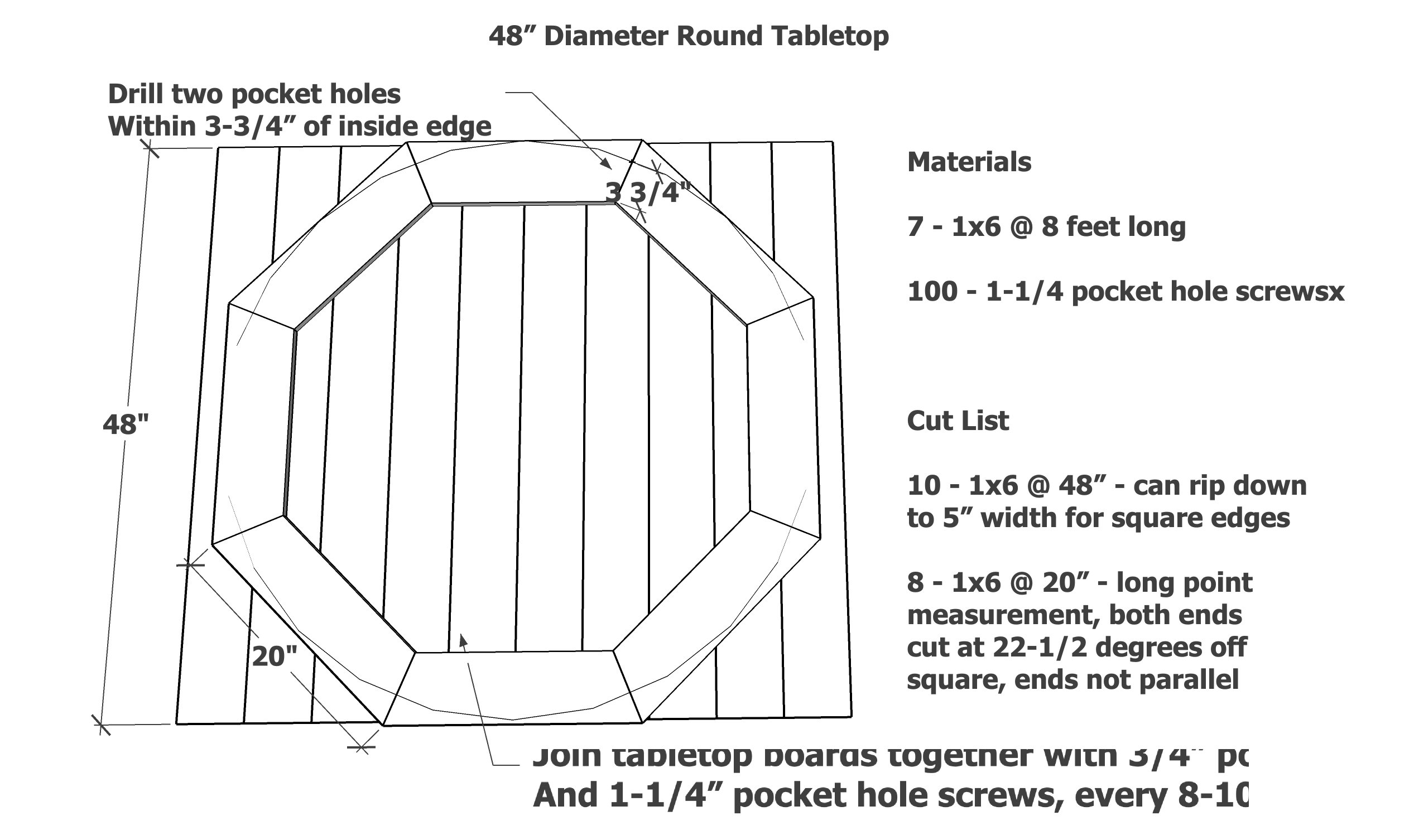

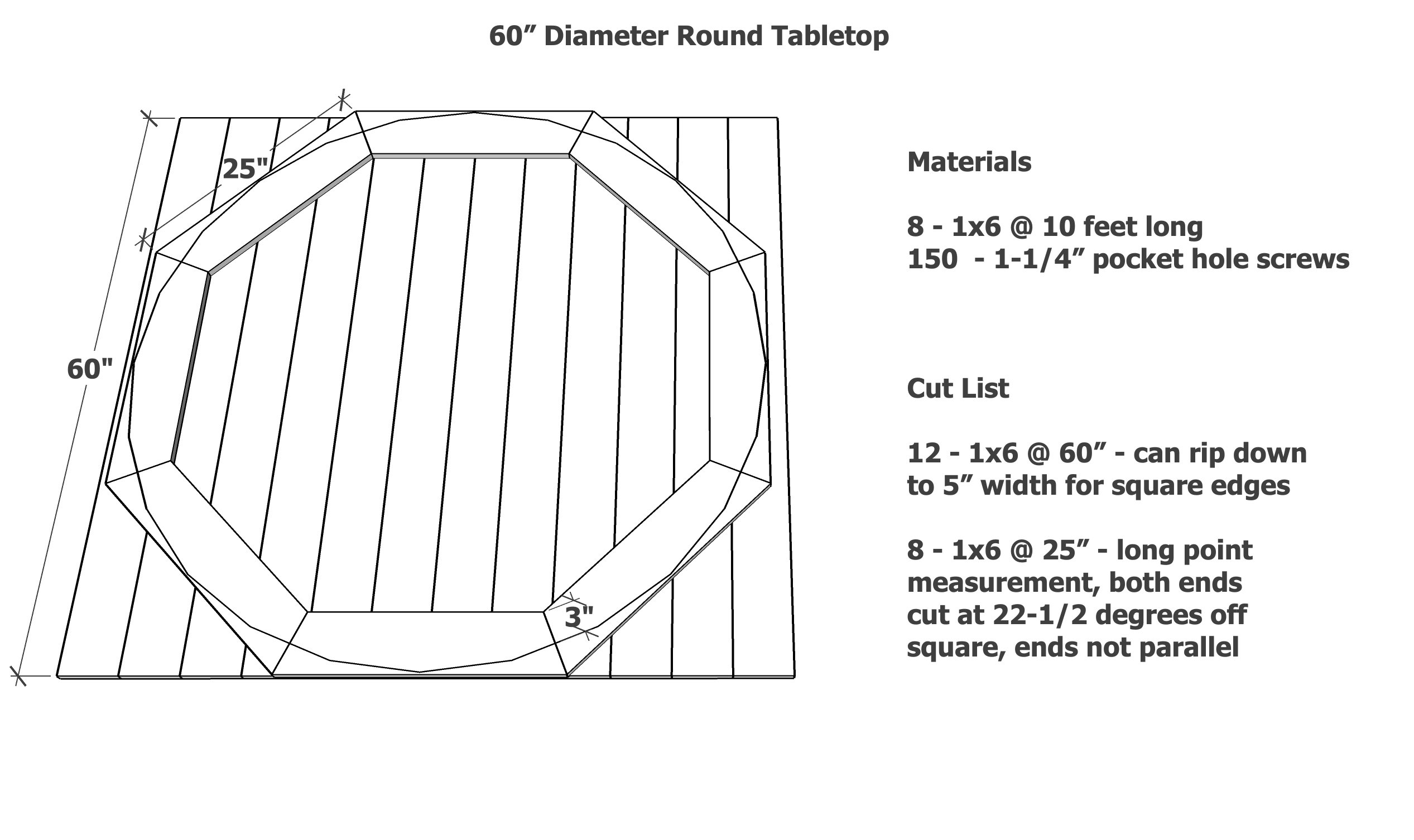

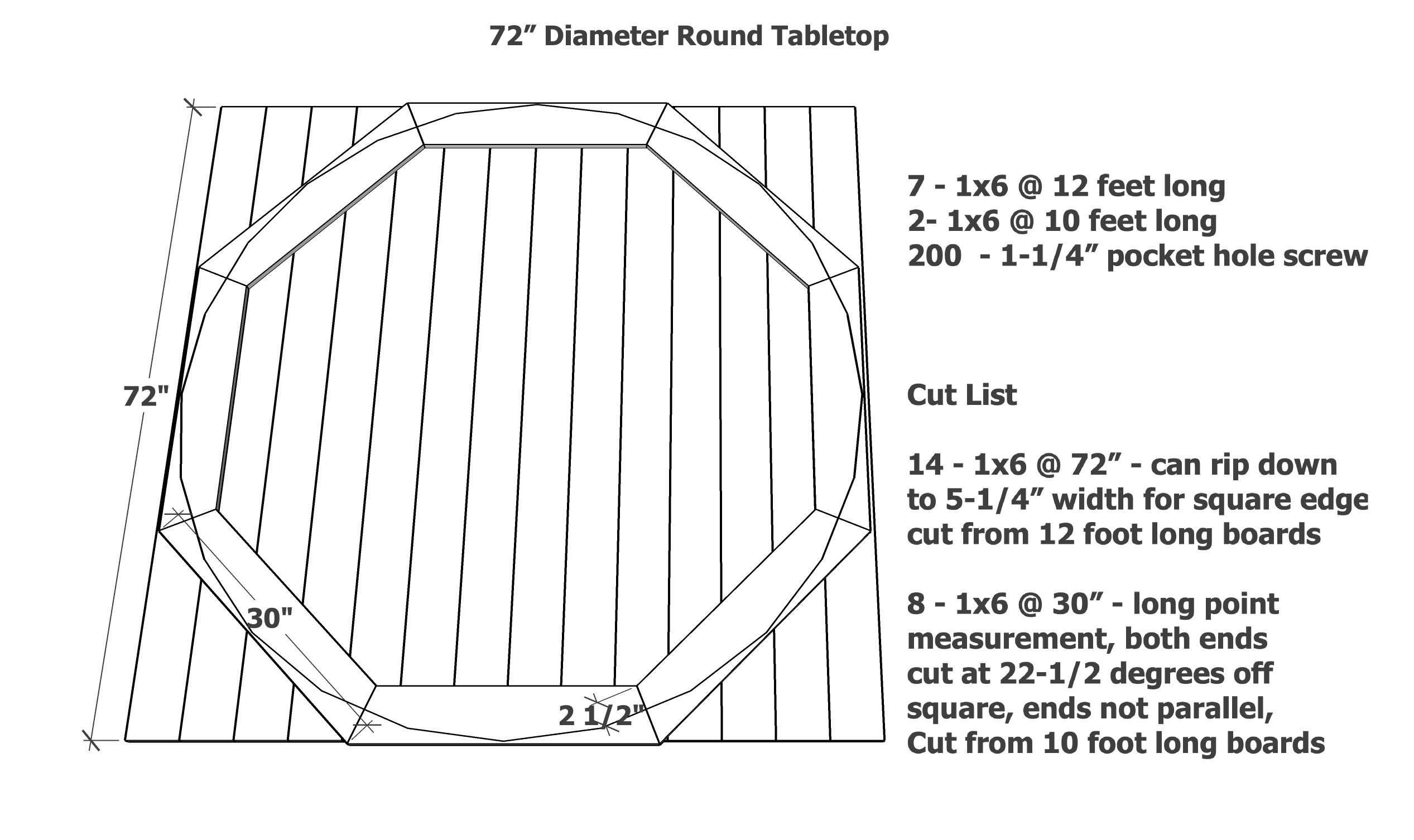

For shopping list, please see the image with pattern in desired size. Pattern images can be downloaded by right clicking.

For cut list, please see the pattern image.

It is recommended to first cut the octagon pieces out first, and attach together.

Then cut the tabletop pieces so they cover the octagon pieces - this may save you some board feet on the end pieces. This also allows for cuts that may be short to be placed on the edges.

Instructions

Step 1

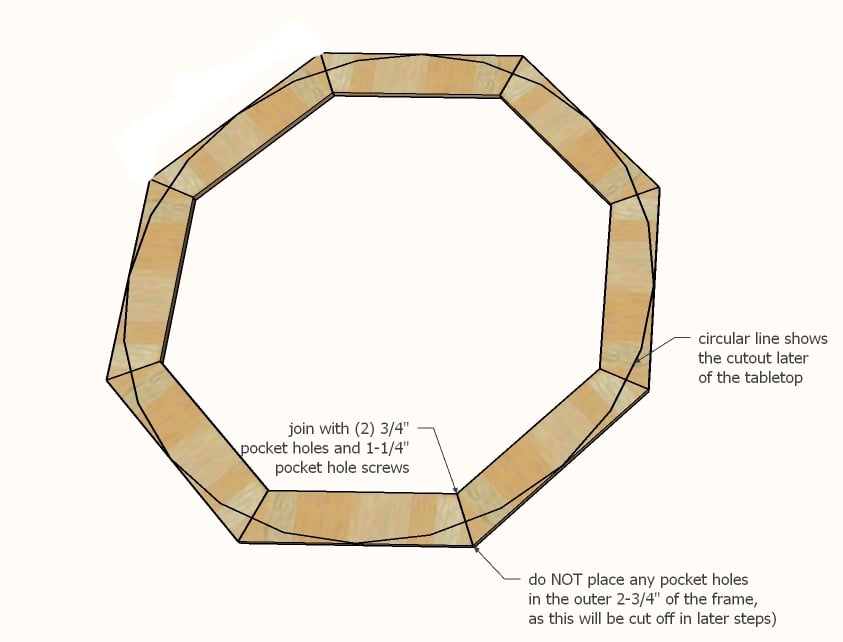

Build the Under Frame

Set your compound miter saw to a 22-1/2 degree angle. Cut out all the frame boards. You can flip the board after cutting to use the previously cut angle pieces as your new angle cut.

Drill two 3/4" pocket holes on ONE end of each of the frame boards, keeping the pocket holes within the circle so they won't show when the excess is cut off in later steps.

Attach with glue and 1-1/4" pocket hole screws to form a giant ring.

Step 2

Building the Tabletop

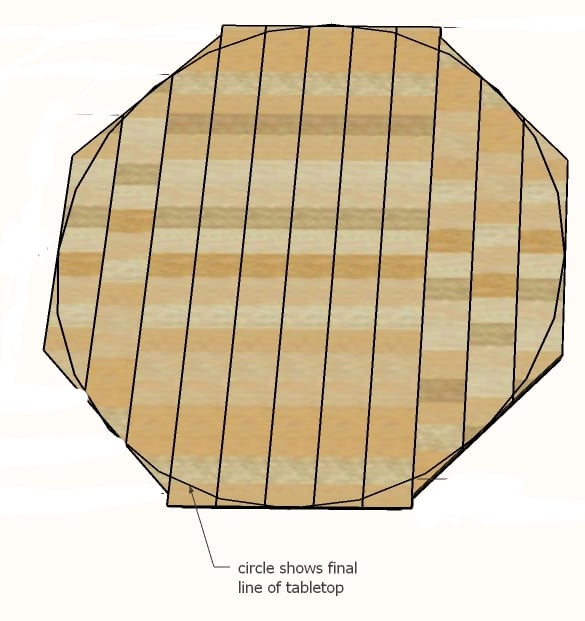

Cut the tabletop boards and and layout, matching centers. You can cut the outer pieces at 45 degrees to save some board feet as shown in the diagram.

Mark pocket holes about every 8" and drill 3/4" pocket holes.

Attach the boards together, matching centers, working from one side to the other. Clamp each joint as you attach.

For this large of a tabletop, if you don't have a worktable that will fit it, two sawhorses with a piece of 3/4" plywood or 2x4s layed flat on top will support it.

Glue the tabletop to the frame. I also recommend 1-1/4" screws to further secure the frame to the tabletop. Avoid placing any screws in areas that will be cut off.

Step 3

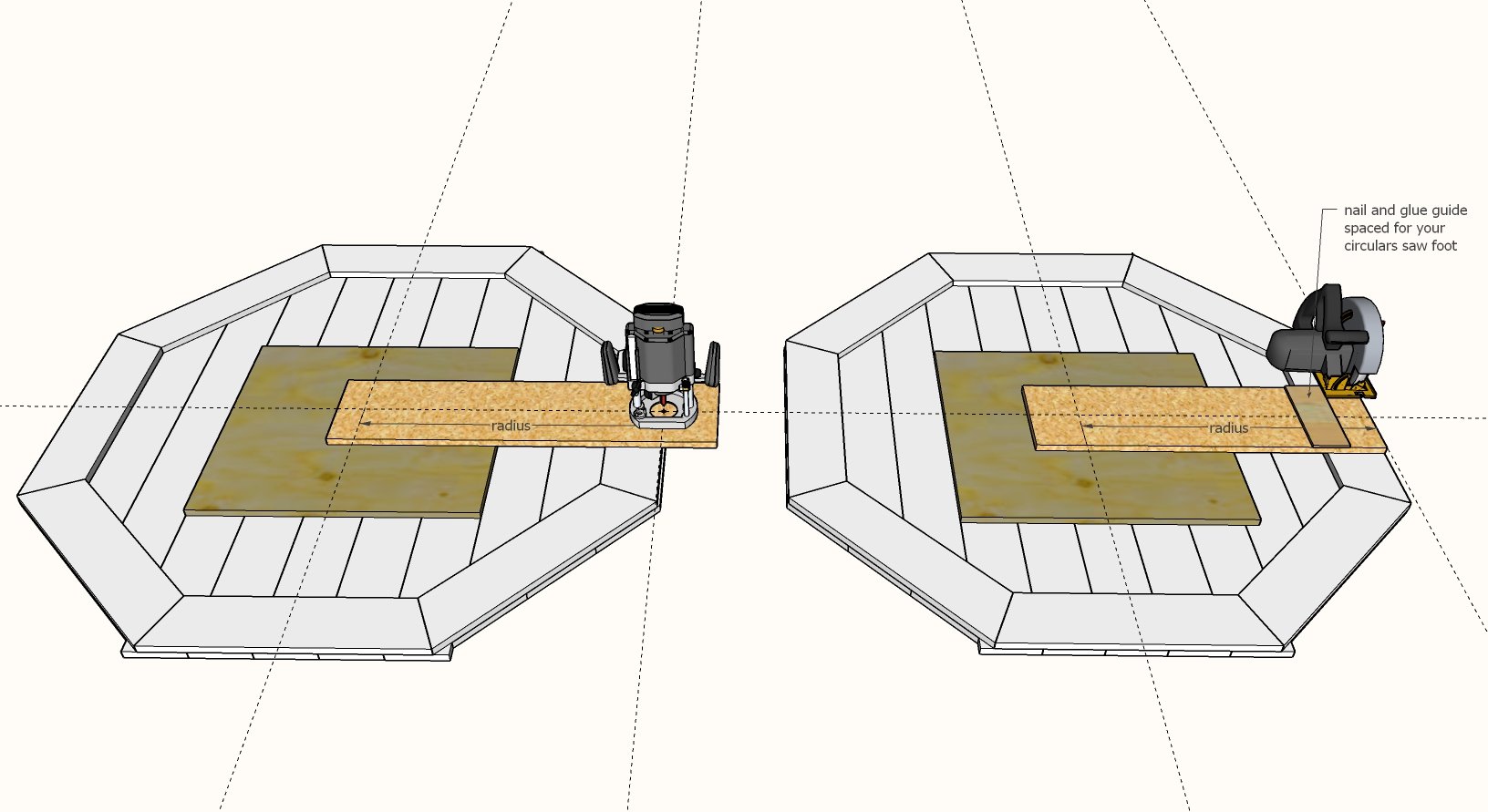

There are two different ways to cut the circle on the tabletop that I frequently use - and my favorite is actually a combination of the two. I like to use the circular saw to cut a rough circle, and then finish with a router bit for a nice edge.

Here is a great tutorial on cutting round tabletops with a router.

Here is how we cut our round table with a circular saw.

The basic steps to build the jig:

- Take a scrap strip of plywood (can be 1/4" or 1/2" thickness) about 8-12" wide and cut it to at least your table radius length, plus 10"

- Attach a 1x2 to the top of the plywood, set in about 2", with brad nails and glue.

- Run your circular saw along the 1x2 to trim the plywood down so it matches the foot of your circular saw.

- Then measure from the cut edge inward the desired radius of your tabletop and drill a pilot hole through.

- Use the pilot hole to attach to the underside of the tabletop in the exact center. 1x blocking will be needed to elevate the center point so it's the same as the 1x6 octagon boards.

The basic steps to use the circle cutting jig:

- Set the circular saw blade to a depth about 1/4" past the thickness of the tabletop.

- Run the circular saw down the 1x2 to cut off excess

- Rotate the jig and repeat, until the table is a circle - depending on how big, this may be dozens of cuts.

- If possible, attach the circle saw to the jig and run it completely around the tabletop for a smooth finish.

I don't like to leave square edges on round dining tables, because it is easy for the wood to break off with a knife edge. So I like to use an ogee bit or a roundover bit in the router to clean it up, just letting the router bit follow the circle cut edge.

Step 4

Then I work up in grit to 220 - or until the tabletop is very smooth.

I always add at least two coats of clear coat, with a very light sanding in between for durability. We did three coats.

Three coats of Vartathane Crystal Clear in satin

Comments

zlillymp

Sat, 09/19/2020 - 17:17

Question

Do you have plans for the bench in the background?

vdonato1122

Tue, 01/26/2021 - 10:12

Do you have the plans for…

Do you have the plans for the base?