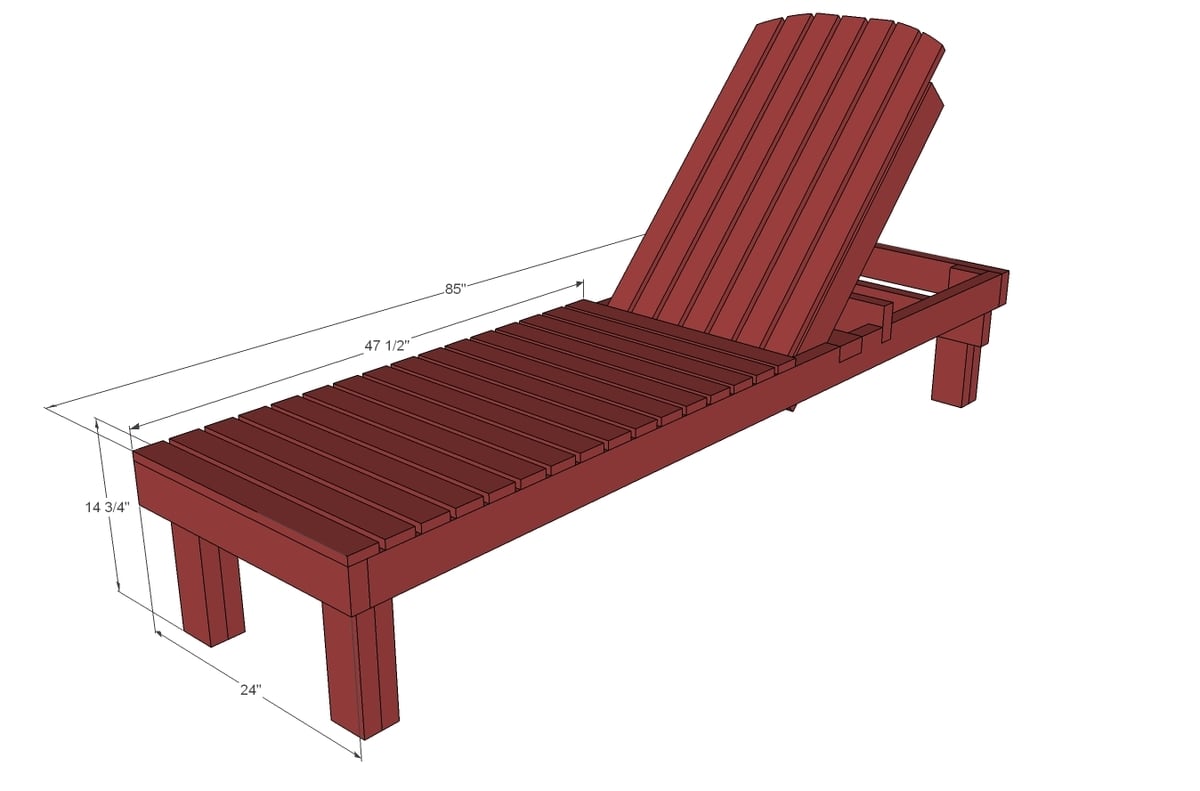

Make your own wood outdoor chaise lounge for a fraction of the cost to buy! Free step by step DIY plans from Ana-White.com

Preparation

2 - 2x6 @ 9 feet long (can be 9 foot studs)

3 – 2x4 @ 8 feet long

8 – 1x3 @ 8 feet long

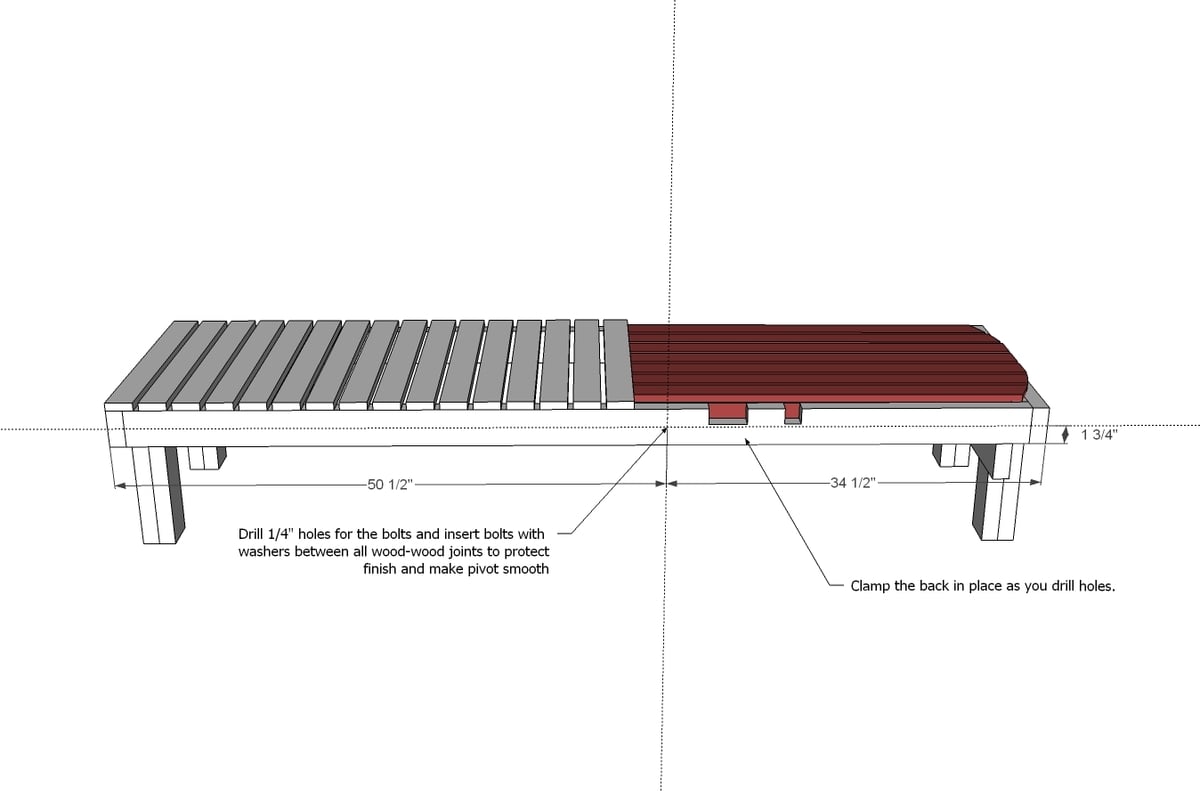

2 – ¼” bolts 4” long with nuts and 6 washers

2-3/4” self tapping exterior wood screws

2” exterior screws or galvanized brad nails and glue to nail slats down with

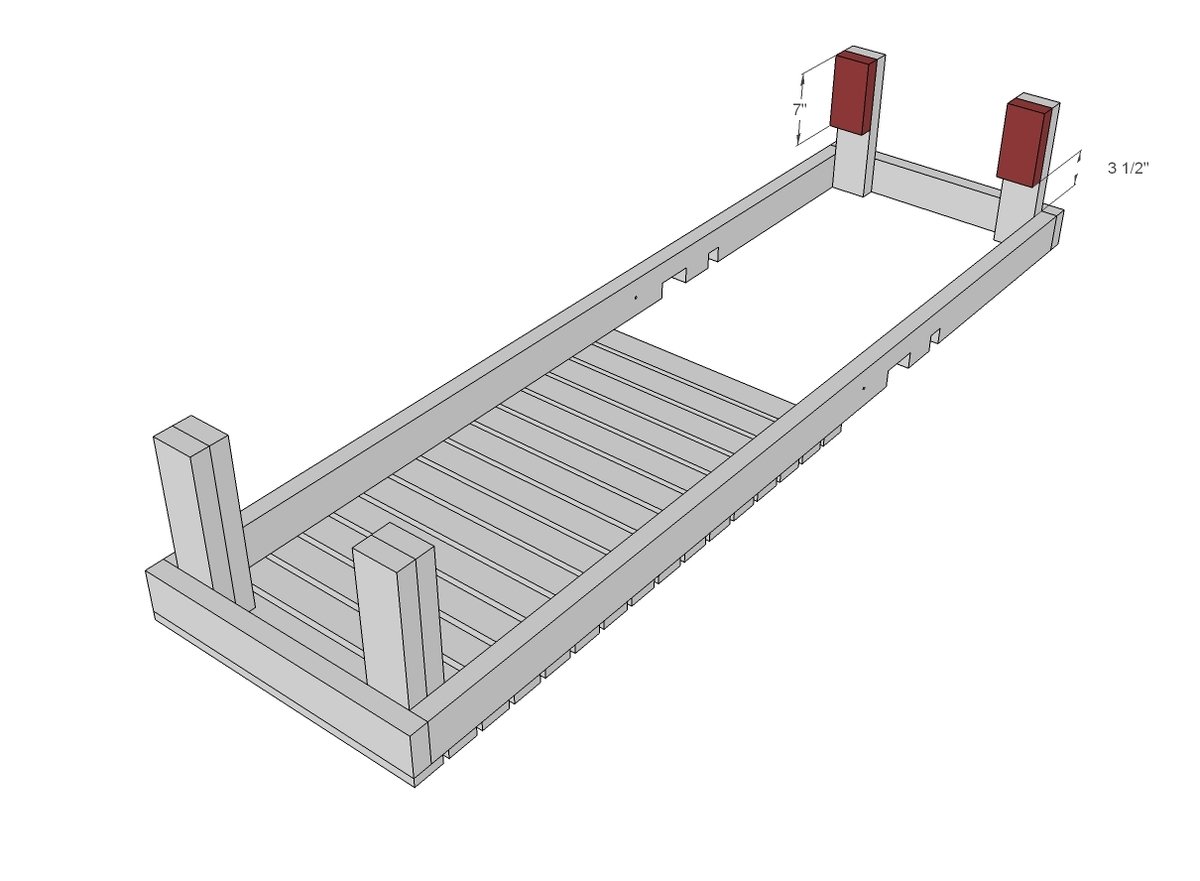

BASE

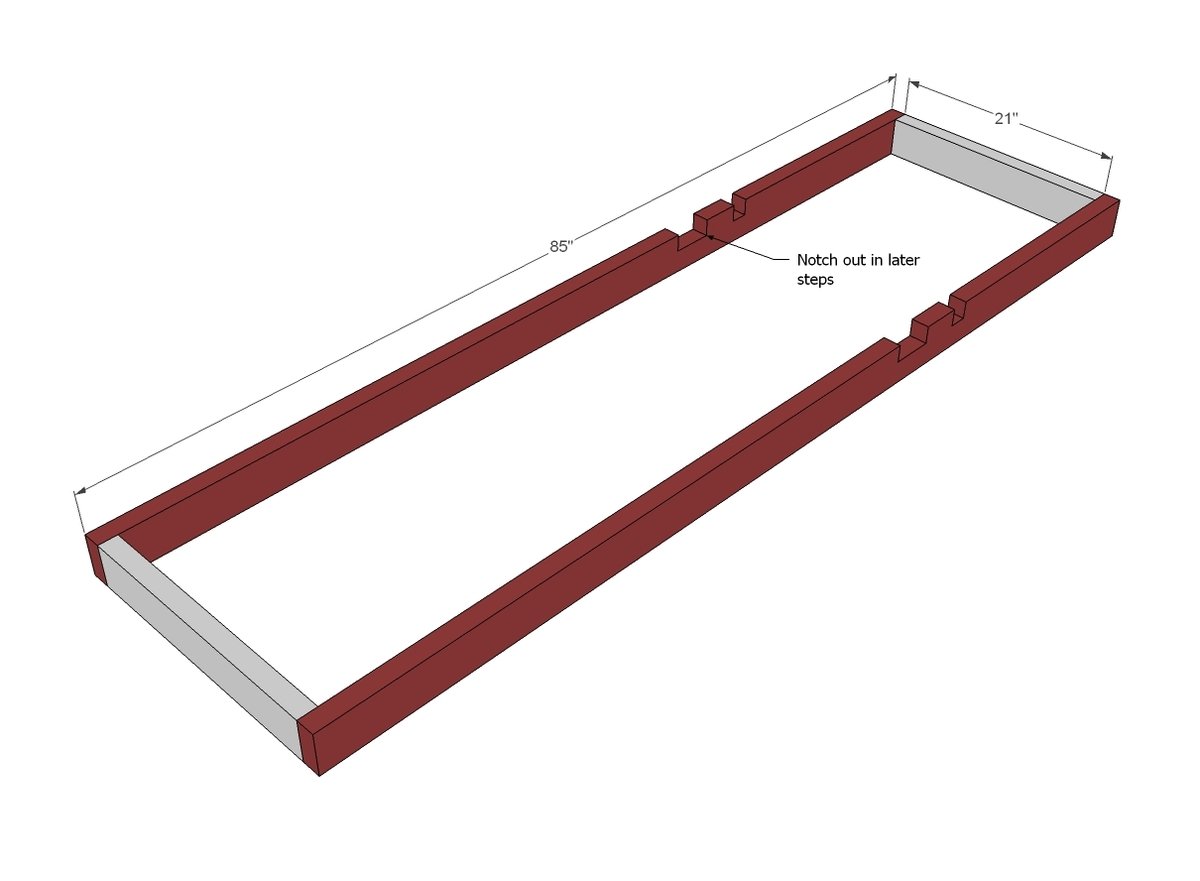

2 – 2x6 @ 85” - main frame sides

2 – 2x6 @ 21” - main frame front/back

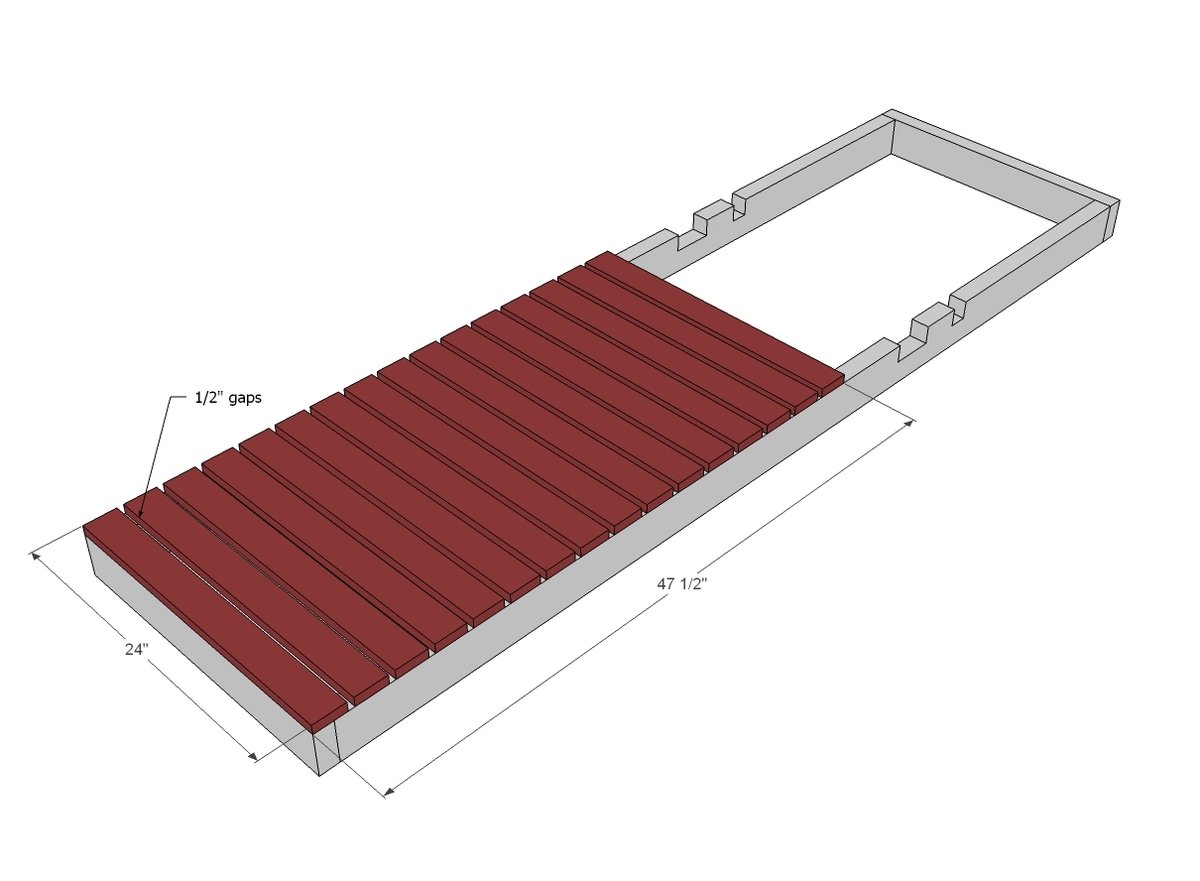

16 – 1x3 @ 24” - seat slats

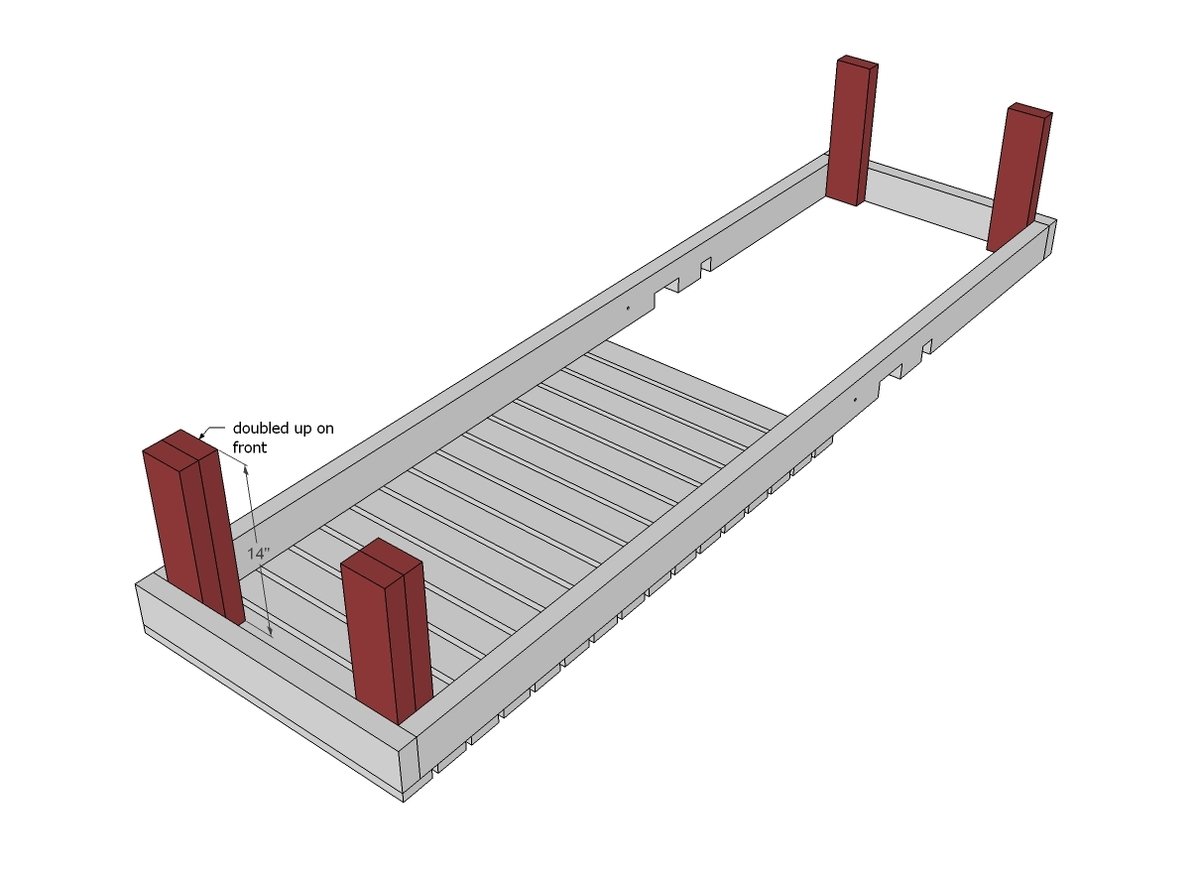

6 – 2x4 @ 14” - legs

2 – 2x4 @ 7” - legs

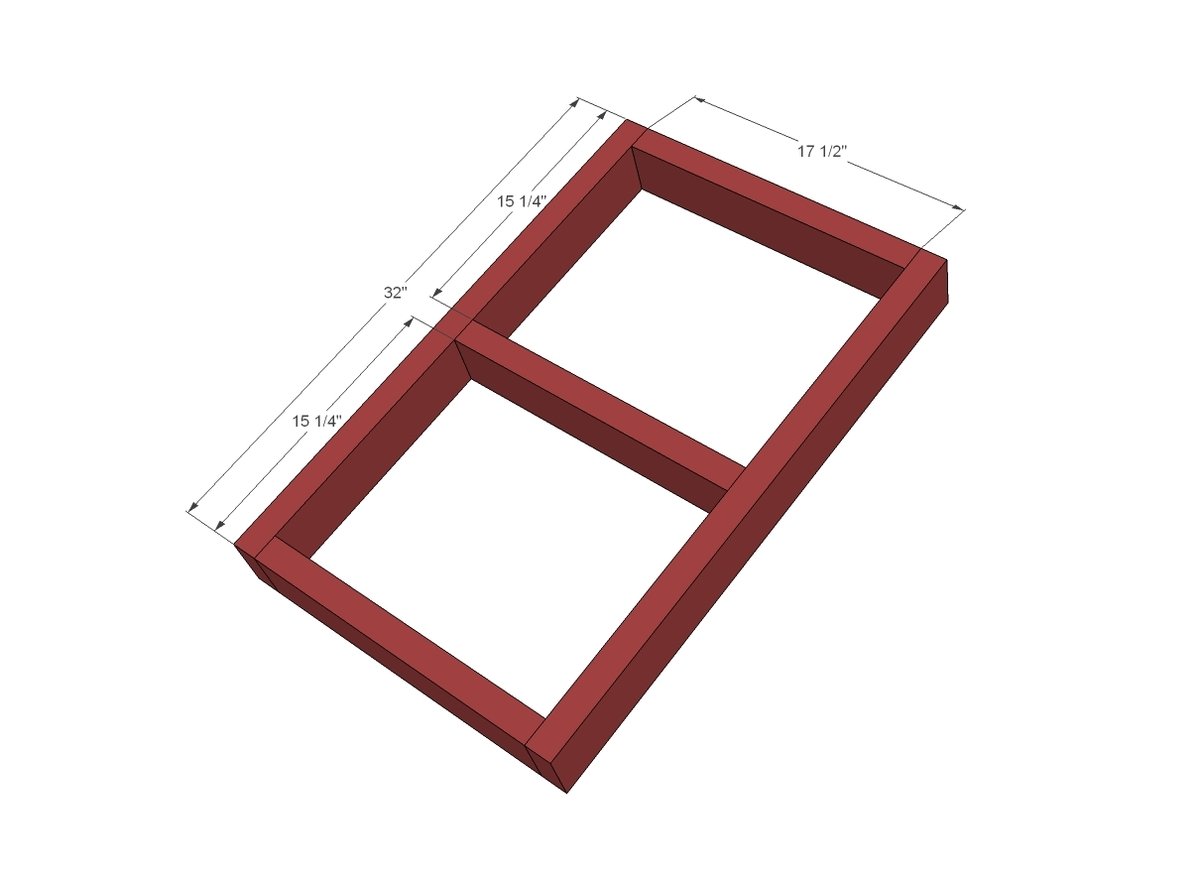

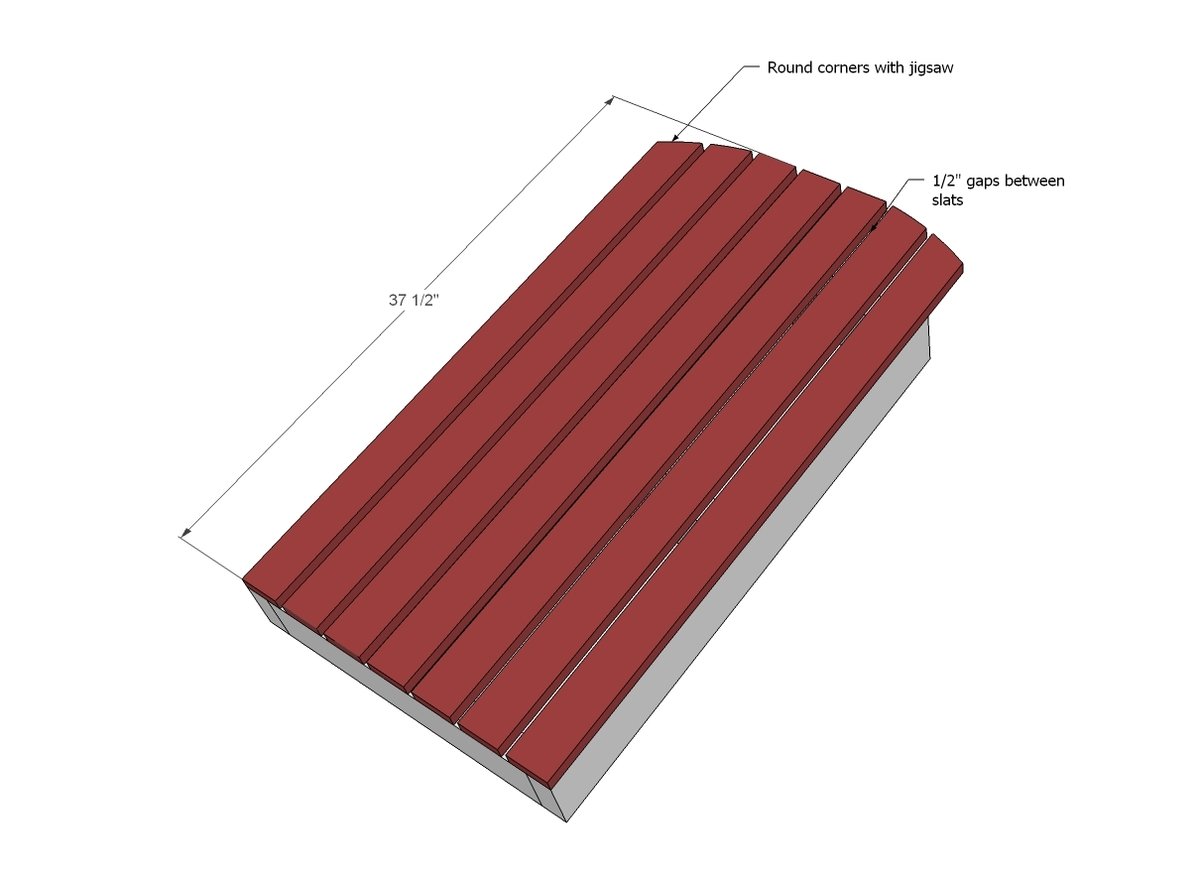

BACK

2 – 2x4 @ 32” - back frame

3 – 2x4 @ 17 ½” - back frame

7 – 1x3 @ 37 ½” - back slats

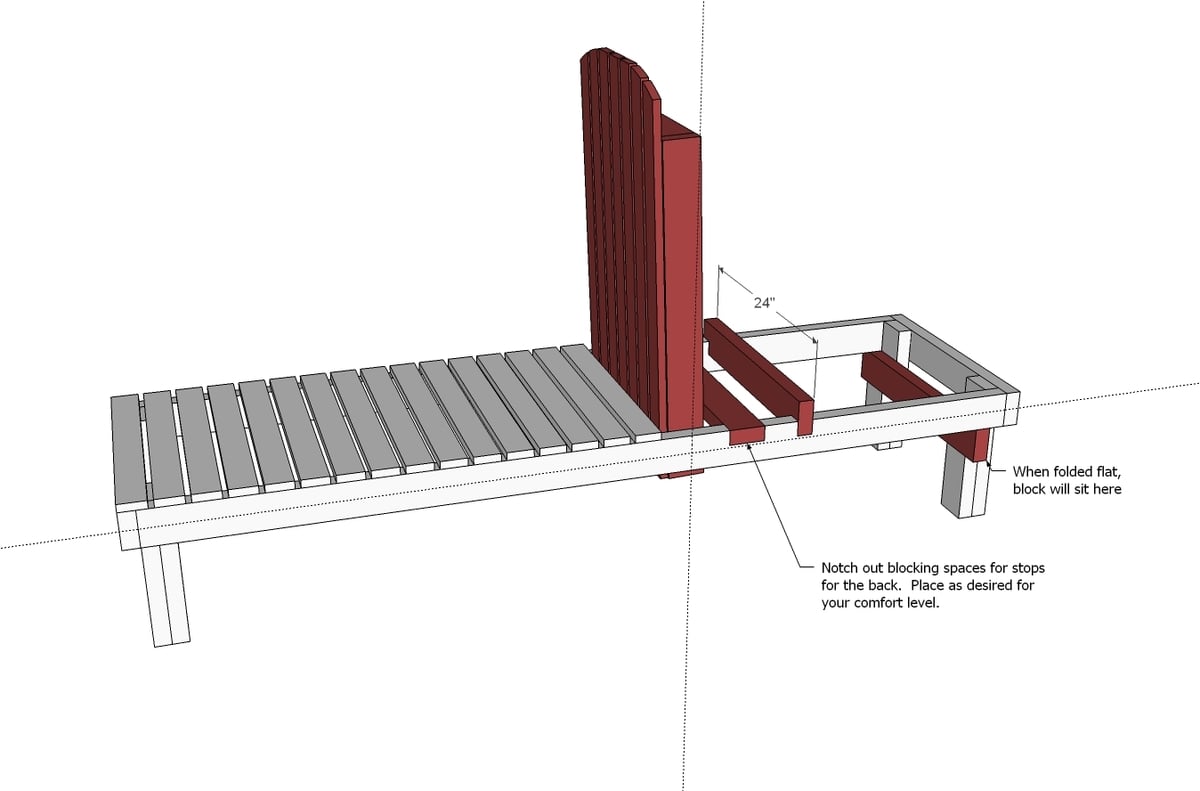

1 – 2x4 @ 24” (stop block)

Instructions

Step 1

Build your frames first. You can use 1 1/2" PHs and 2 1/2" PH screws OR 2-3/4" countersunk screws.

I do recommend the PHs because it will hide your screws holes, making it easier to paint the pieces, and then attach later through the PHs.

NOTE: The diagrams show 2x4s. We have updated this plan per user recommendations to use 2x6s for the frame.

Notch out for the back support with a jigsaw.

Step 3

Step 4

Step 6

Step 7

Step 8

Brook is also sharing with us her step by step finishing tutorial here to get this amazing finish!

Comments

markw

Wed, 06/06/2012 - 12:33

Stop Block Notches

What are the measurements/locations of the stop block notches in the base frame? The first step says to add them in a later step, but I'm not seeing that step - or did I miss something :)

In reply to Stop Block Notches by markw

Ana White

Thu, 06/07/2012 - 11:43

Hi Mark - I asked Brook to

Hi Mark - I asked Brook to place the notches where she felt they would be most comfortable to you.

SingleMomThriving

Thu, 06/07/2012 - 08:08

Can I see a picture of the Pivot Bolt?

It's helps when I am shopping to know what to look for. Is it one long bolt or two at each end.

Liquid6 (not verified)

Fri, 06/08/2012 - 06:37

RE to SingleMomThriving

You will need 2 - 1/4" bolts that are 4 inches long. You will need 2 nuts to match the threading on 2 bolts. You will also need 6 washers with 1/4" holes.

Start on the outside. Thread one bolt through a washer, slide the bolt through the whole on the outside rail, add one more washer, add the back of the chair, add another washer and then the nut on the end. This should allow the back to move independently.

May I recommend you use stainless steel hardware.

FlyingMatilda

Thu, 06/14/2012 - 11:59

Slide-out desk...?

Great plans! I'd love to see a modification for a little slide-out desk like the one from World Market! But if I had a great big stump, I'd use it for a side-table instead, too...totally cute. Great plans, wish I had time to do this this season...maybe next!

Theo Rioles (not verified)

Wed, 06/20/2012 - 04:19

screws

hi--bought the 2.5" Kreg screws to affix the slats: went straight up through! set jig at 1.5"...

Theo Rioles (not verified)

Wed, 06/20/2012 - 05:23

screws

hi--bought the 2.5" Kreg screws to affix the slats: went straight up through! set jig at 1.5"...

EleyAnn (not verified)

Mon, 06/25/2012 - 12:23

What Kind of Wood?

From someone whose big accomplishment this year was learning how to use a dremmel to build a pinewood derby car (cute but not fast), I have a few layman questions . . .

1. The plans provide specifications, but do not indicate the type of wood . . . does that matter?

2. Does the type of wood contribute to the life of the chaise lounger? Or do other things matter like stain/paint?

3. My husband is a big guy 220-240 lbs . . . provided I can actually build it correctly, will it hold his weight?

Thank youI love this site and if I can pull this off, I think I will double major in mommying and wood shop and build lots more stuff!

Tami220 (not verified)

Mon, 08/27/2012 - 10:15

Great Questions

These are great questions...was a reply ever sent? I wouold like to know the answers as well :)

Thanks

Tami

In reply to What Kind of Wood? by EleyAnn (not verified)

jigganancy

Mon, 08/27/2012 - 11:13

1. The plans provide

1. The plans provide specifications, but do not indicate the type of wood . . . does that matter?

... usually, no.

2. Does the type of wood contribute to the life of the chaise lounger? Or do other things matter like stain/paint?

... if it's outdoor, yes. It's good to use cedar or pressure treated outside. Waterproofing staining is supposed to last longer than paint.

3. My husband is a big guy 220-240 lbs . . . provided I can actually build it correctly, will it hold his weight?

... when building your own furniture, sometimes its trial and error. My finance is about 200 lbs and sits on the chaise just fine. If you're really concerned, you might want to tweek the legs or the support with beefier wood like 2x4.

Tami220 (not verified)

Mon, 08/27/2012 - 10:16

EleyAnn's Questions

These are great questions...were they aver answered? I would love to know myself...thanks :)

Tami

EleyAnn (not verified)

Mon, 08/27/2012 - 11:17

Questions not answered (yet)

I am probably going to make this my winter project with my husband so that we have a lovely set come Spring/Summer out here in California.

If I get to it first, I will let you know Tami!

Eley :)

In reply to Questions not answered (yet) by EleyAnn (not verified)

jigganancy

Mon, 08/27/2012 - 11:20

Hi, Eley - I just tried to

Hi, Eley - I just tried to answer your questions above

Elliott Strom

Tue, 06/11/2013 - 15:21

Cutting Diagram

Hi Ana,

I just began working on this project for this week. And one thing I came up with that might be very helpful to anyone tackling this project is a detailed cutting diagram. Is there a way for me to post an image file or PDF file? This diagram helps to make sure all the pieces can be cut from the amount of lumber in the shopping list.

Thanks!

jennilynne16

Mon, 06/23/2014 - 12:54

Cutting notches?

I'm wondering what tool to cut the notches with? Specifically speaking, I don't have a jig saw, unfortunately. All I have is a circular saw and a sawz-all (sp?). I'm hoping that doesn't put this project on a "can't do" list for me. But I can't imagine how in the world to cut those notches with what I have.

papabear

Mon, 06/30/2014 - 22:07

cutting notches

all you need is a circular saw, a chissle, and a hammer.

Using circular saw cut through the wood in straight lines about a 1/4 to a 1/2 inches wide. next use hammer to knock out the wood t obe removed . finally use hammer and chissle to remove the rest of the wood in the notch and smooth it out with chssle for a good fit. i hope i have been of somehelp.

papabear

vickie458

Mon, 06/23/2014 - 16:12

Stop Block

hello can someone please help me I am stuck. I have the chaise lounge built, I'm having a hard time understanding how the stop block and notches work. Do you attach the block to the legs? The back of the chair? I'm really confused with the step.

dsipe

Sun, 05/17/2020 - 14:56

Stop Block Help

How do you get the stop block to fit when the chair is fully reclined with the new plans?