Do you want a farmhouse table, but don't want to spend thousands of dollars? Have you thought about building your own? Check out this free, step by step plan to build your own with basic tools. From Ana-White.com

Preparation

- 8 – 2x4 8 feet long

- 6 – 2x2s 8 feet long

- 1 - 2×8 8 feet long

- 7 – 2x6s 8 feet long

- 2 3/4″ Self Tapping Wood Screws (About 100) (try spax brand or similar)

- 4″ Self tapping wood Screws (About 20)

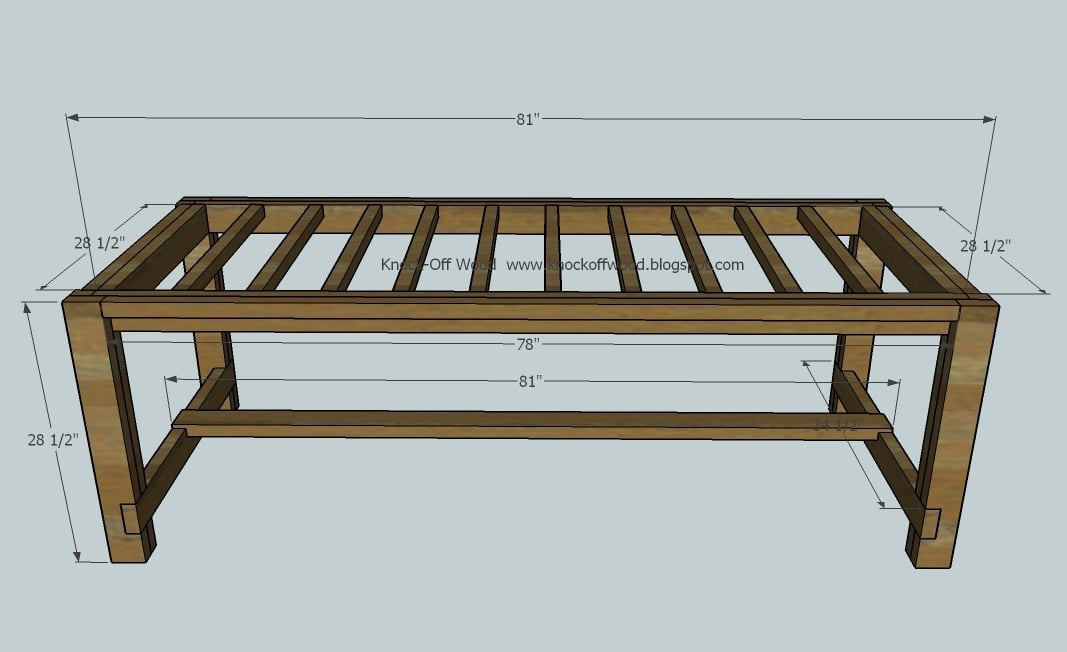

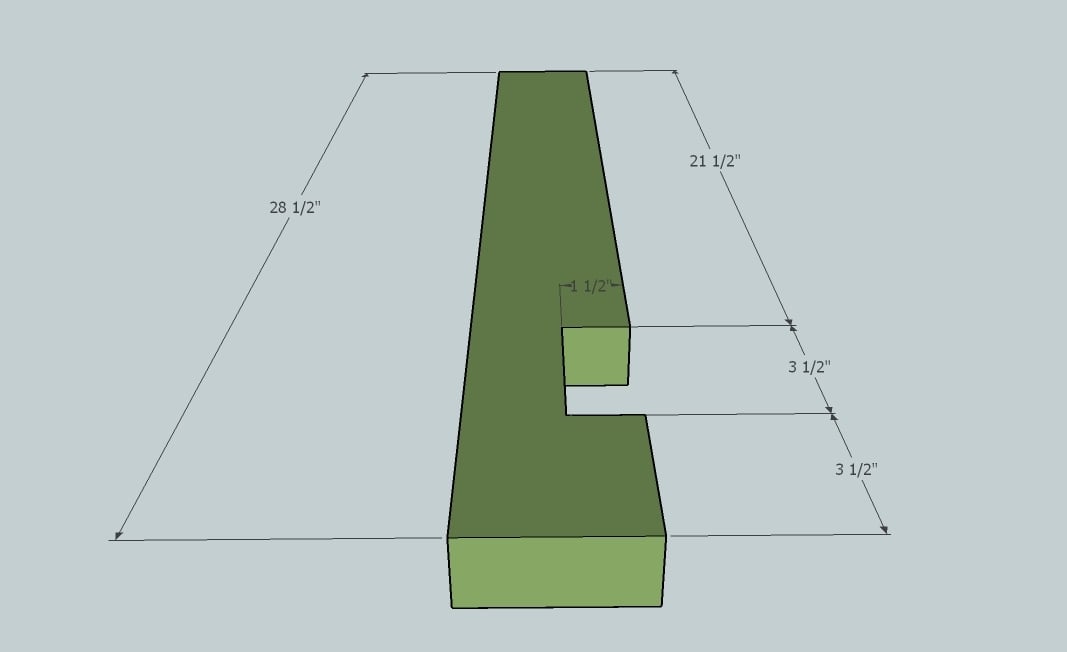

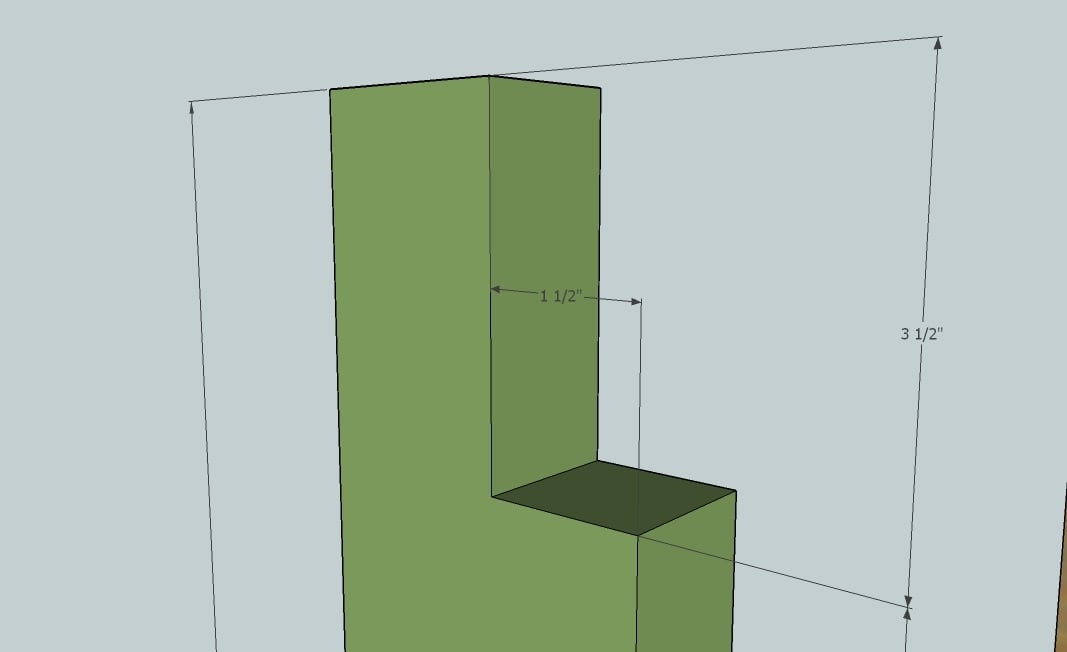

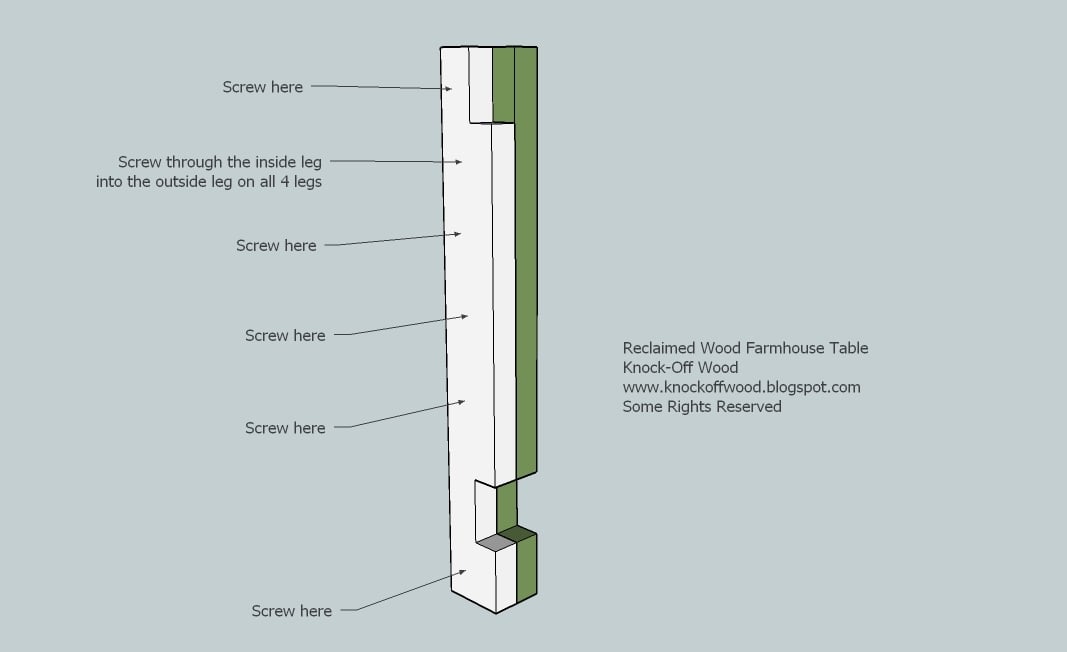

A) 4 - 2×4 @ 28 1/2″ (Outside Legs)

B) 4 – 2×4 @ 28 1/2″ (Inside Legs)

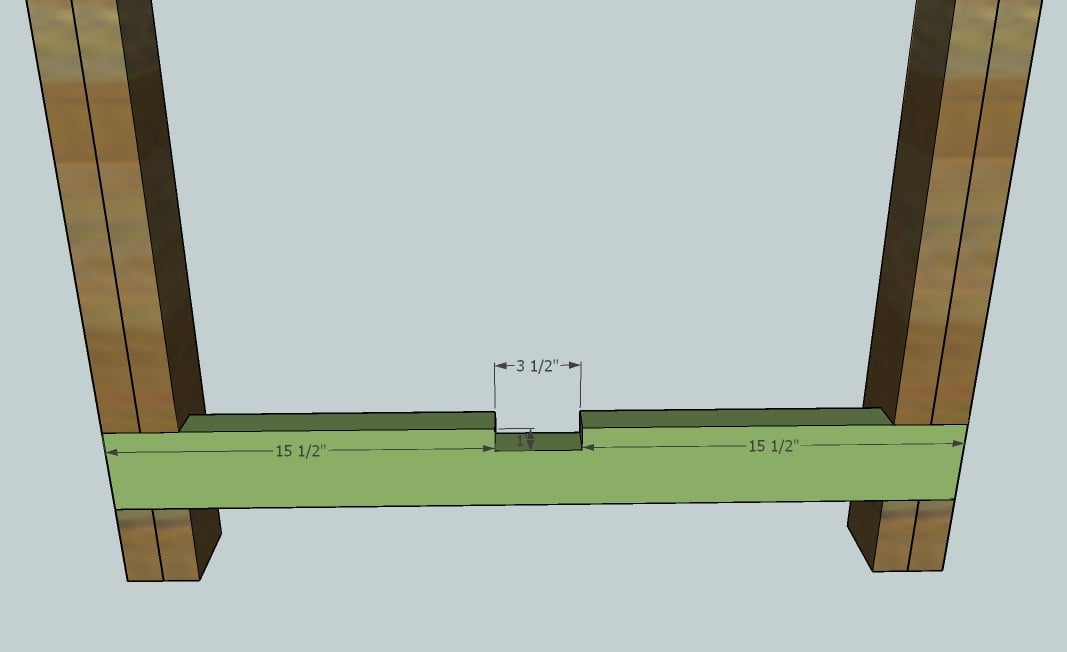

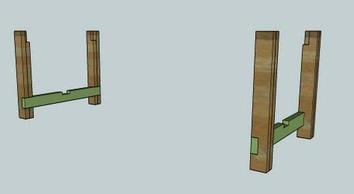

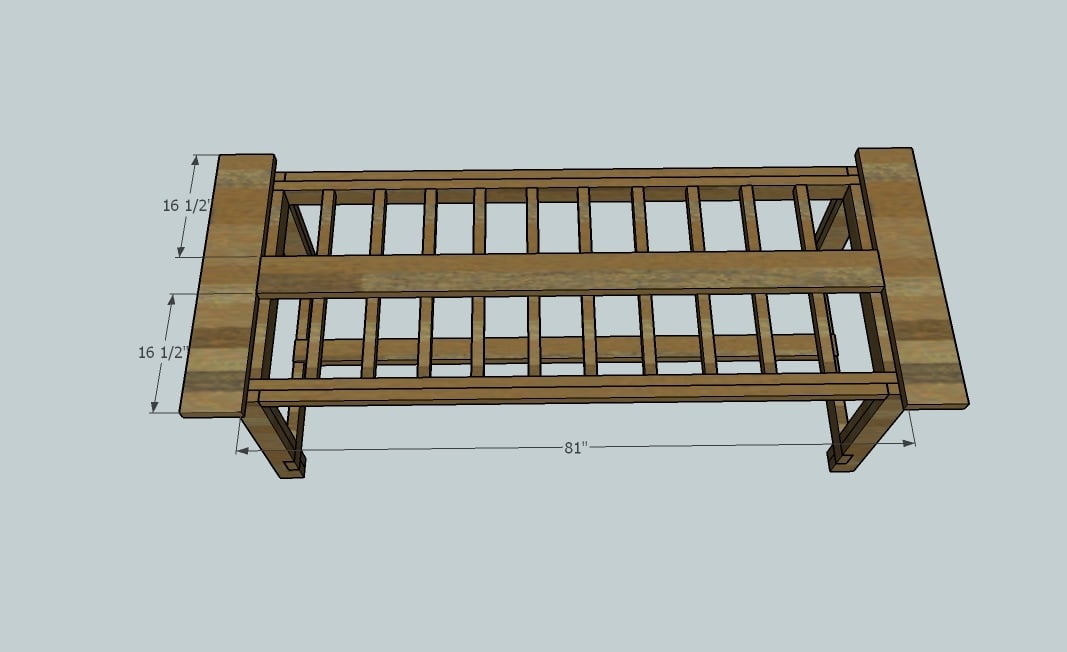

C) 2 -2×4 @ 34 1/2″ (Bottom End Supports for the Stretcher)

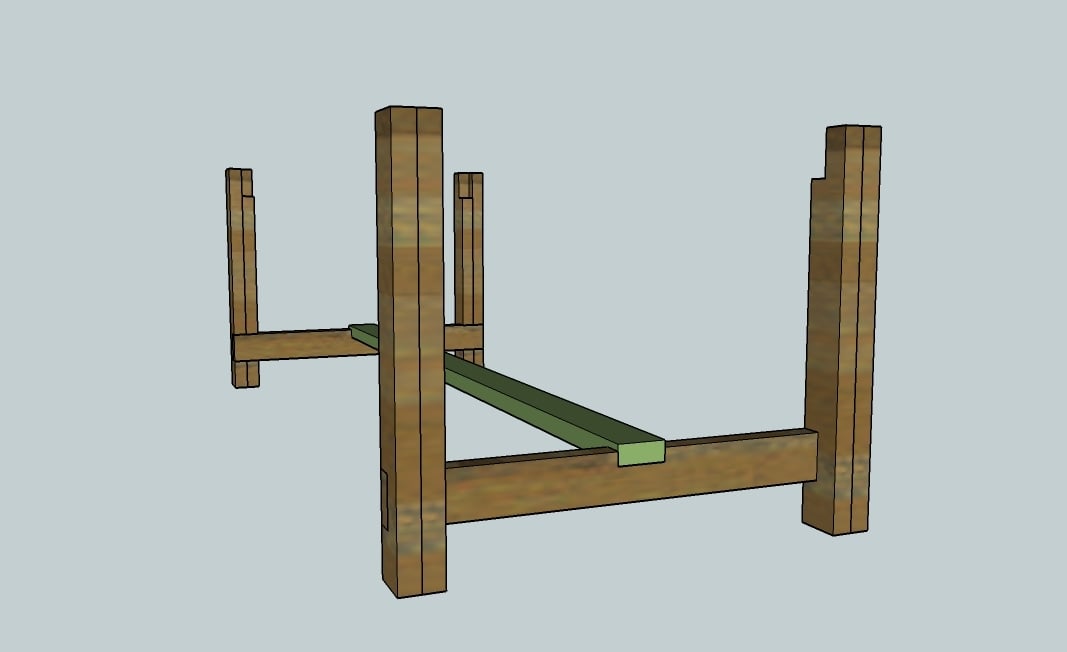

D) 1 – 2×4 @ 81″ (Stretcher)

E) 2 – 2×4 @ 81″ (Side Aprons)

F) 2 – 2×4 @ 28 1/2″ (End Aprons)

G) 2 – 2×2 @ 28 1/2″ (Overhang Supports, Ends)

H) 2 – 2×2 @ 78″ (Overhang Supports, Sides)

I) 10 – 2×2 @ 28 1/2″ (Under Tabletop Supports)

J) 2 – 2×8 @ 38 1/2″ (Breadboard Ends)

K) 7 – 2×6 @ 81″ (Tabletop Pieces)

Start by cutting all your boards. The best way to cut is with a compound miter saw. You can also use a circular saw with a guide - good square cuts are very important.

Always use glue. Use the longest possible screws, and predrill with a countersink bit to hide the screw heads.

Instructions

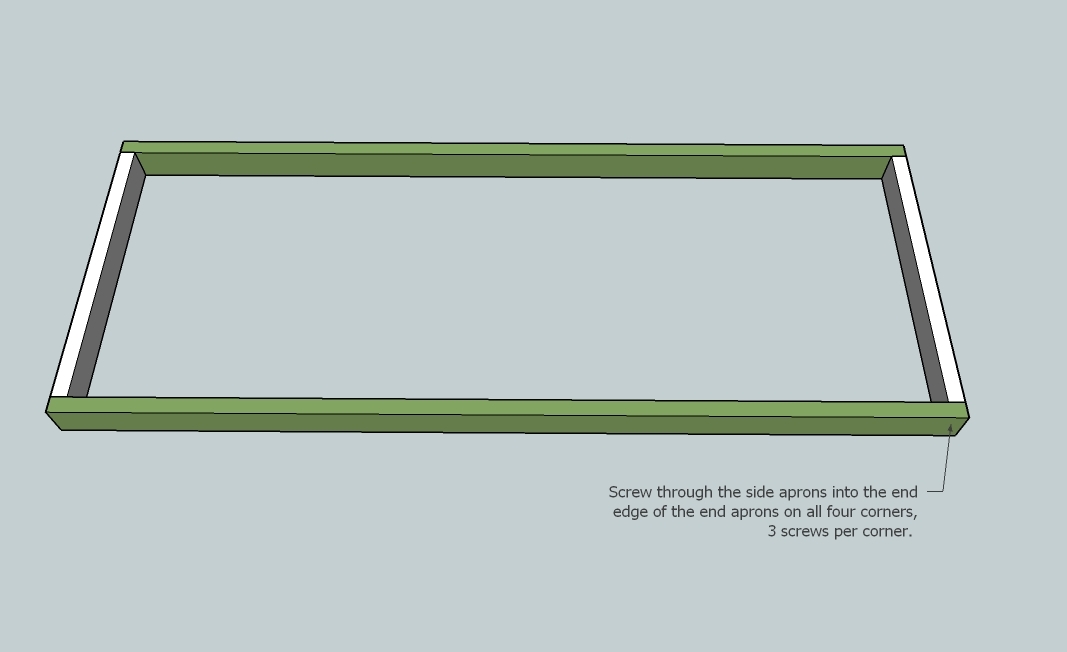

Step 1

Step 2

Step 4

Step 6

Screw the support, C, into the legs, as shown above. Make sure you use 2 screws on the inside leg and 2 screws on the outside legs per side of the end supports. NOTE: If you would like the support to be on the outside, rotate the legs, keeping the inside legs on the inside, and add 4″ to your stretcher, D. This will reduce your leg room for end chairs, but the notch out will be more visible, like my table and the Restoration Hardware table.

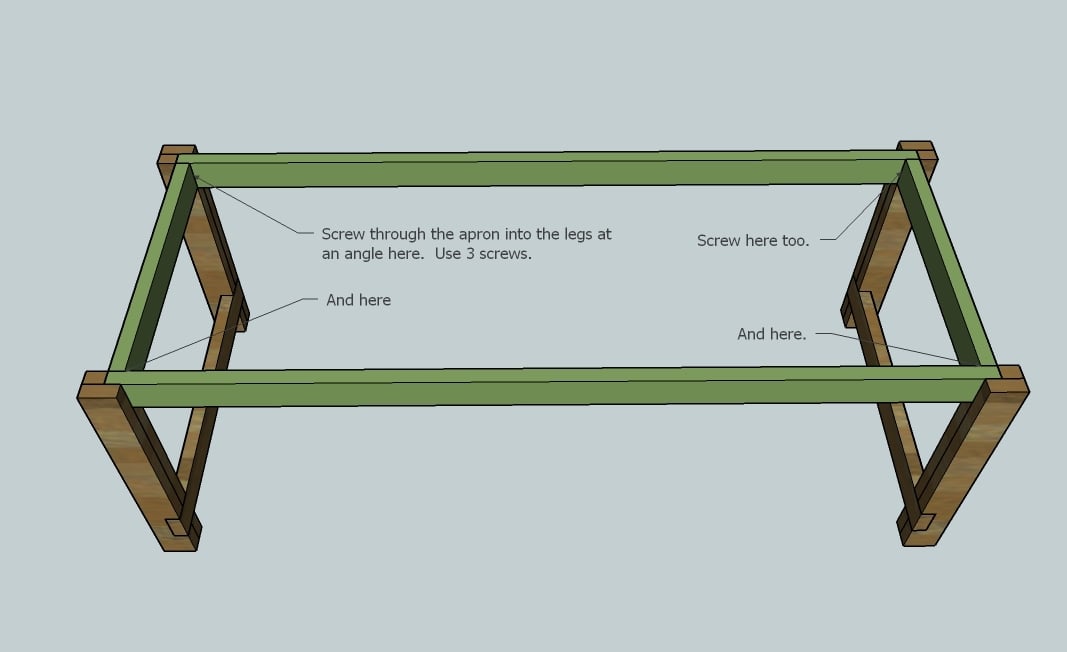

Step 8

Step 9

Fit the apron frame into the base of the table as shown above. Use the long screws to screw at an angle through the apron into the legs. Use 3 screws per leg on all legs. Lots of glue here. Now is a good time to check your table for square. Visit the HOW-TO section if you do not know how to check for square.

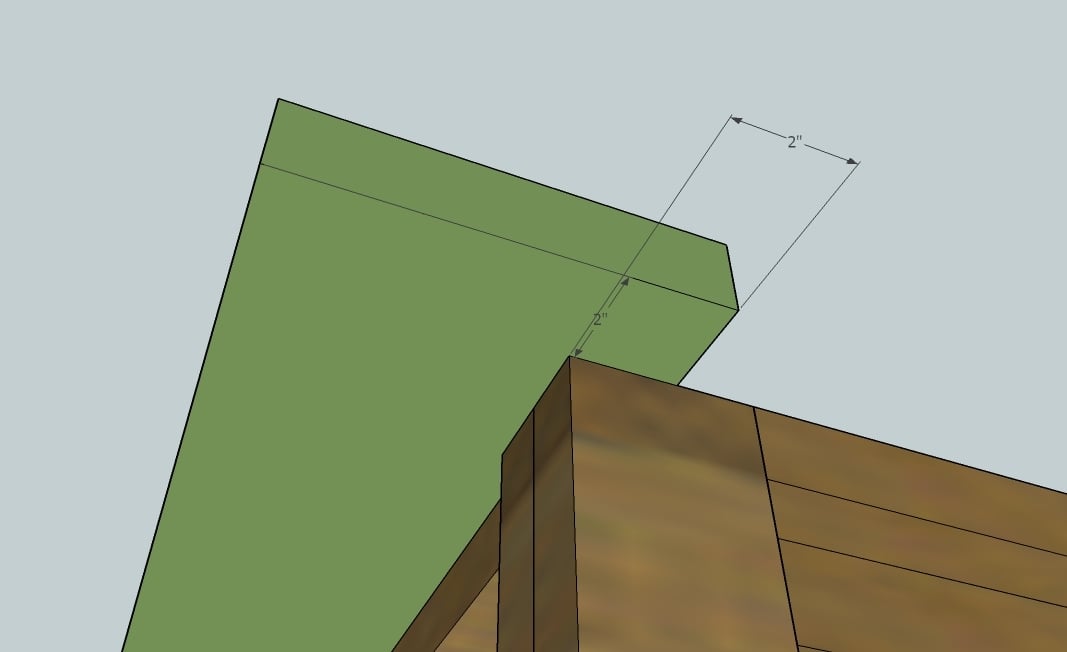

Step 10

Step 11

Step 13

Step 14

Step 15

Step 16

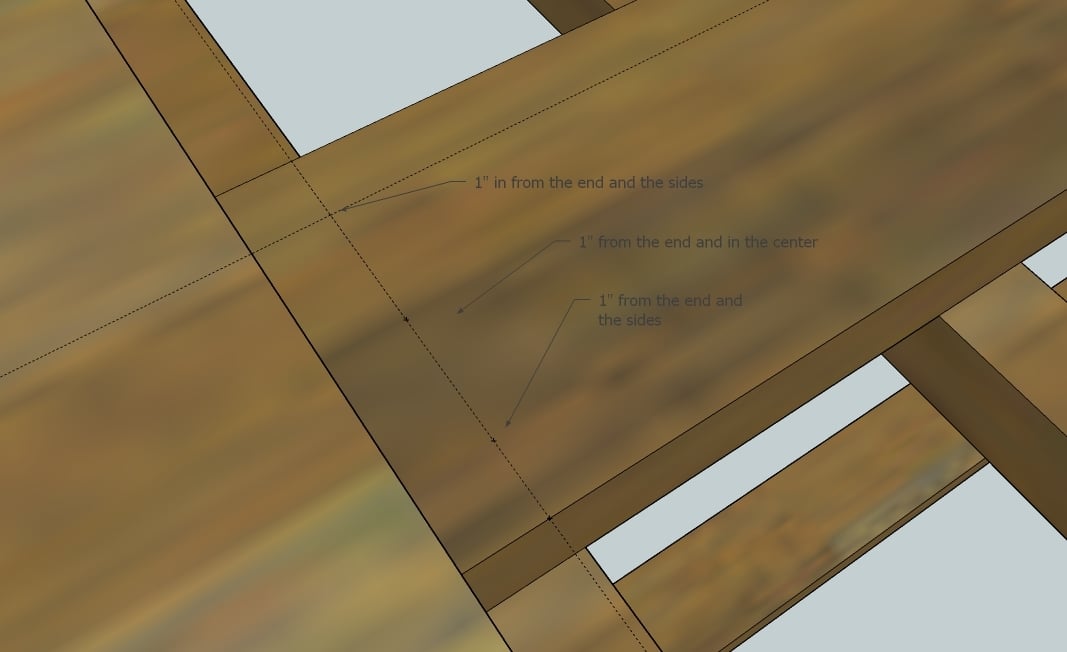

Add the next tabletop boards, K, as shown below. As you screw each board down, take special care to line up the edges with the existing boards. You do not want a gap between the boards on the tabletop. Remember to screw through the top on the ends and then screw through the bottom of the under supports to the underside of the tabletop boards.

After all the boards are screwed in place, then use the long screws to screw through the tabletop boards into the breadboard ends, as shown above.

Sand the entire table with 120 grit sandpaper, working in the direction of the wood grain.

Refill holes with wood filler if needed.

Sand table with 180 grit sandpaper.

Stain or paint. If the table feels rough between coats, lightly sand with 180 grit sandpaper.

A final coat of poly on the top can help keep the top easy to finish and wipe cleanable.

Comments

dankdodgers

Wed, 12/28/2016 - 17:44

Would love to if I can! :)

So what seems to have happened? Is the stain splotchy?

Jeanne624

Thu, 12/29/2016 - 08:09

Yes. It seems where I used

Yes. It seems where I used the wood filler. It is very blotchy.

Littlelady84

Wed, 02/15/2017 - 09:28

Lumber

Hi, I'm brand new to this site and fairly new to woodworking. I was wondering what kind of lumber is used for this project? Also, do you have any recommendations on where to purchase it?

tjaburke8

Tue, 02/21/2017 - 06:47

Make without the stretcher?

Would it still be sturdy if it was made without the stretcher support beam? My fiance is concerned about people hitting their shins on the stretcher, but I'm concerned about the table not having proper support. Any suggestions?

tjaburke8

Tue, 02/21/2017 - 06:52

Make without the stretcher?

Would it still be sturdy if it was made without the stretcher support beam? My fiance is concerned about people hitting their shins on the stretcher, but I'm concerned about the table not having proper support. Any suggestions?

Michele H

Thu, 11/21/2019 - 10:41

Spax requested screw size do not exist

HELP!!! Spax Screws in the size on the shopping list, are not available!!

Not sure where way I should change size -up or down??

Spax does not make a 2 3/4 size screw.

Please advise.

Thanks

Time

Fri, 01/03/2020 - 17:06

could you use a 4 X 4 for…

could you use a 4 X 4 for legs instead of 2- 2X4s ?

Clint

Mon, 01/27/2020 - 19:05

I’m close to the end on this…

I’m close to the end on this build, granted it’s one of my first big builds, but the Breadboard ended up being about 2 inches short. I.e the tabletop pieces together extend farther than the breadboard. Any thoughts around this?

mcronin

Sun, 07/19/2020 - 06:59

Great Plans

Thank you for offering these plans. They were easy to follow.

I just finished one and am very happy with the outcome. I made a few adjustments to the published plans so that it would fit the deck it will be placed on as well as the legs. I used 4x4s and notched accordingly. I prefer the solid look. I also capped the screw holes in the legs and supports rather than use wood glue. Finally, used pegs to secure the table planks from the top while also using screws from the bottom. Used Cabot's Australian Timber Oil on the framing and top.

If I was to build again the only change I would make would be to cut all the vertical table planks to length first and then place on the frame. Finally butt the breadboard ends to the planks. My cuts, despite using a strength edge still stink.

Moving in to the benches.

timh11263

Tue, 09/08/2020 - 08:10

Step 16

Saw several questions about Step 16 but didn't see any answers. Can you clarify how to use the long screws to screw through the tabletop boards into the breadboard ends?

STEP 16

Add the next tabletop boards, K, as shown below. As you screw each board down, take special care to line up the edges with the existing boards. You do not want a gap between the boards on the tabletop. Remember to screw through the top on the ends and then screw through the bottom of the under supports to the underside of the tabletop boards.

After all the boards are screwed in place, then use the long screws to screw through the tabletop boards into the breadboard ends, as shown above.

AmbassadorTim

Thu, 09/02/2021 - 15:40

First Build = Farmhouse Table

Thanks for these plans. I built this table as my first real adventure into DIY. I was very nervous. The plans were very easy to follow. I now have a great pace for the entire family to sit together and eat dinner. No more dinners where people are are all over the house. The bench was perfect for my two kids and two nephews to sit at.

chelwags

Sat, 09/11/2021 - 06:21

Farmhouse table

Where are the white chairs from in the second picture?!

tjlichat

Wed, 02/09/2022 - 14:58

farmhose table no pocket or screws from top

Great plans and instructions. I would recommend however to dry fit the cut pieces before gluing and fastening to avoid any problems with how to keep everything square and avoid missteps.

We chose not to drill and screw from the top but added a few extra supports for boards which seems to work well. Also added a support for the bread board to out side legs.

Would like to send a picture but could not figure that out here.