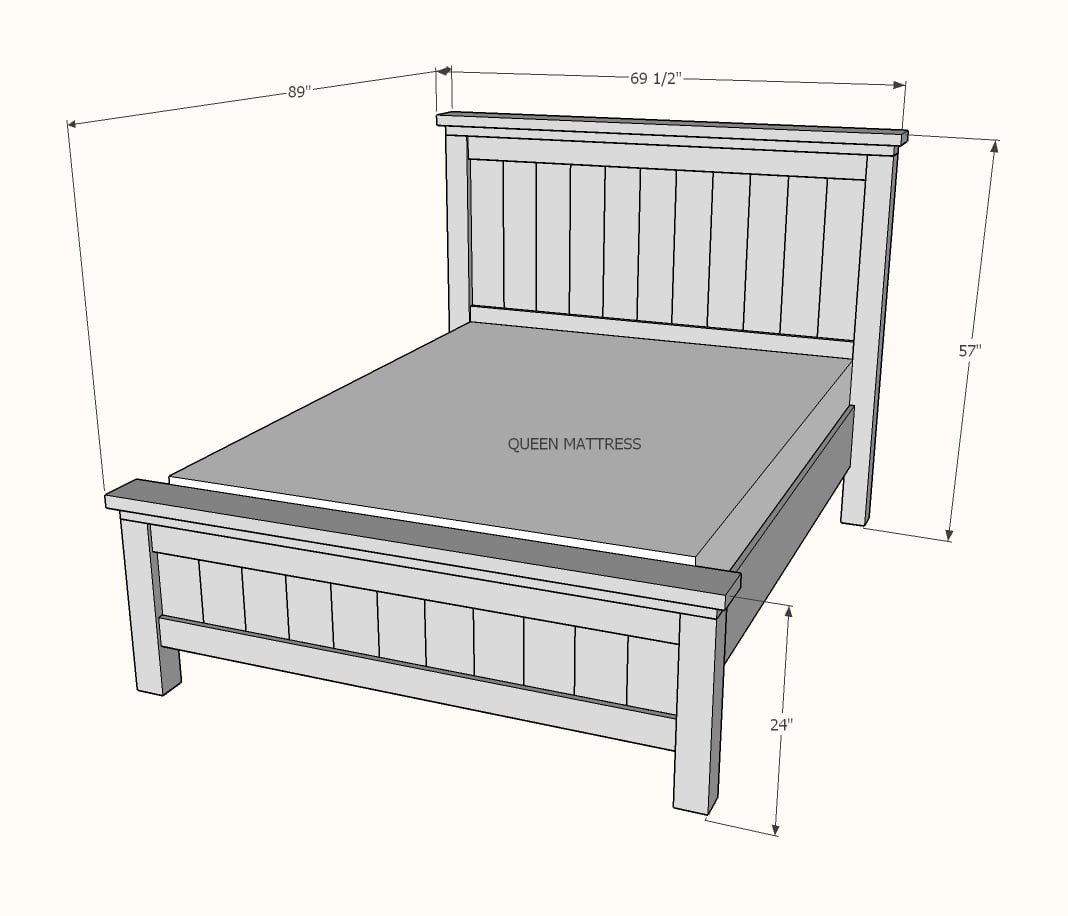

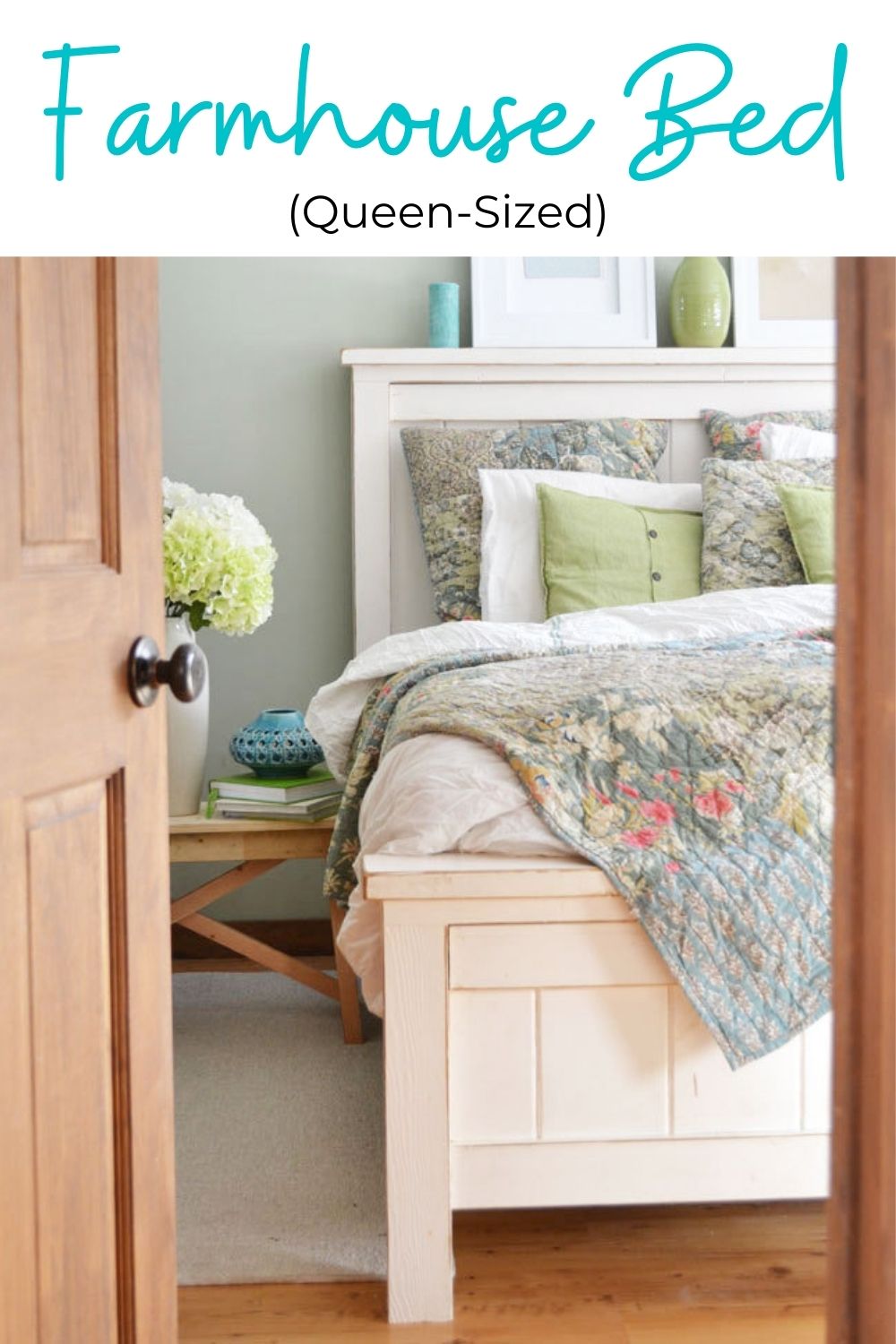

This beautiful farmhouse bed can be made for just a fraction of the cost to buy - all from standard, off the shelf lumber! You won't need a pocket hole jig or any special tools to build.

This bed has been built thousands of times and is a reader favorite. You can also find the twin version, king version, and all our farmhouse bed plans here.

Preparation

- 12 - 2x4 8 feet long

- 2 - 2x6 8 feet long

- 2 - 1x10 8 feet long

- 2 - 4x4 8 feet long

- 1 - 2x2 8 feet long

- 6 - 1x6 8 feet long

- 4 - 1x4 8 feet long

- 100 - 1-1/4" long brad nails

- 75 - 2-1/2" long self tapping wood screws (#8 star bit recommended)

HEADBOARD CUT LIST

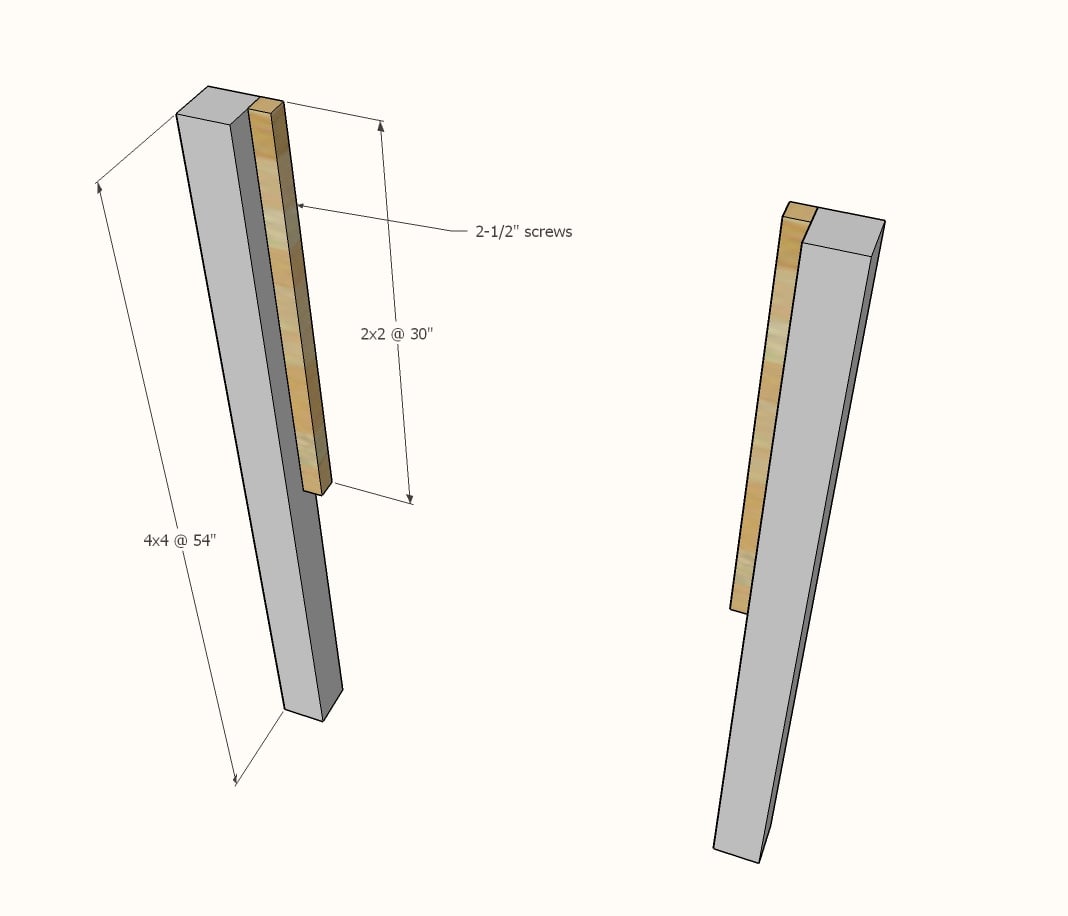

- 2 - 4x4 @ 54"

- 2 - 2x2 @ 30"

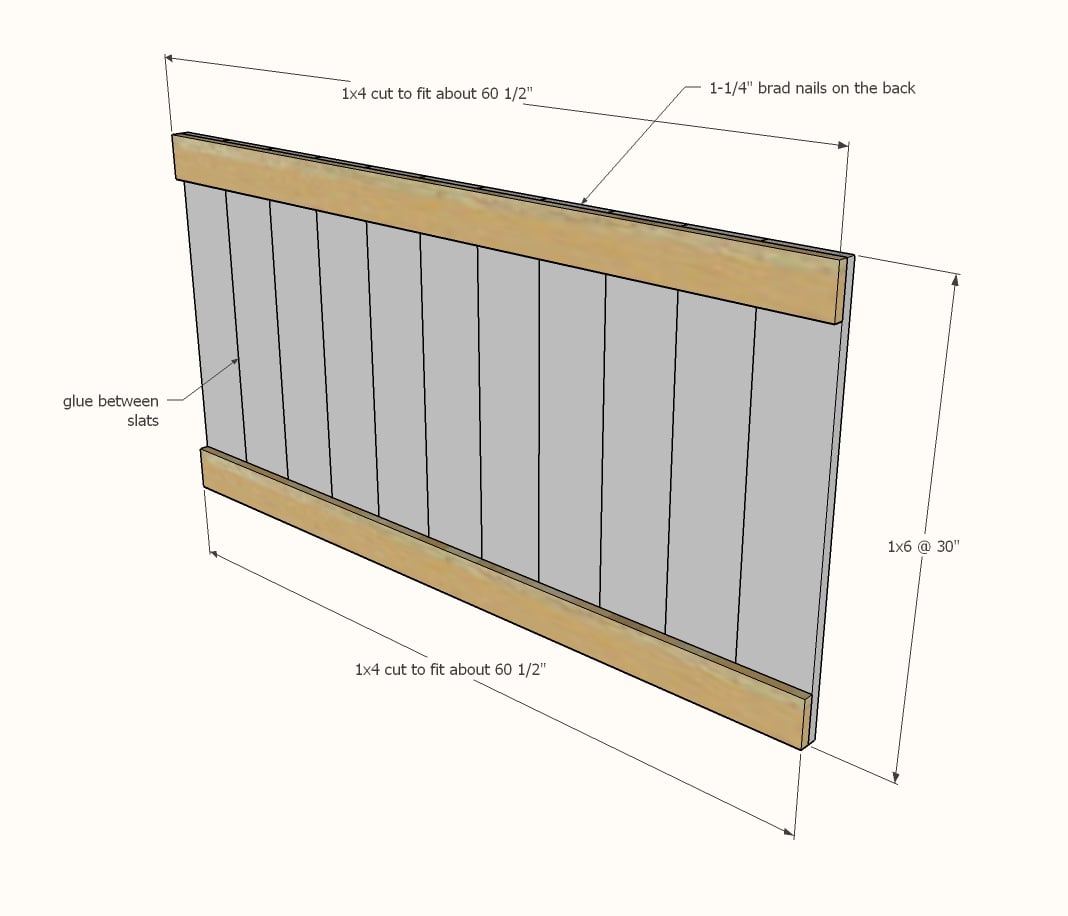

- 11 - 1x6 @ 30"

- 2 - 1x4 @ about 60-1/2" - measure and cut to fit

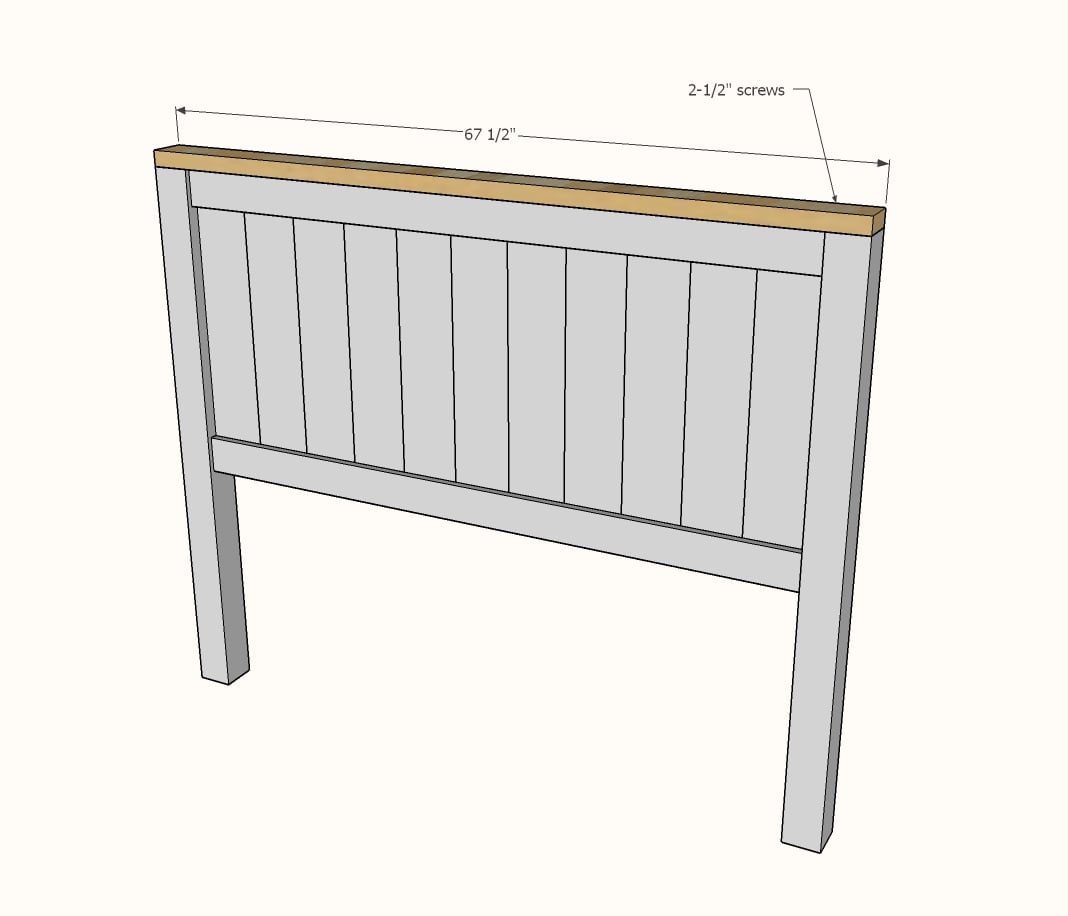

- 1 - 2x4@ 67-1/2" - measure and cut to fit

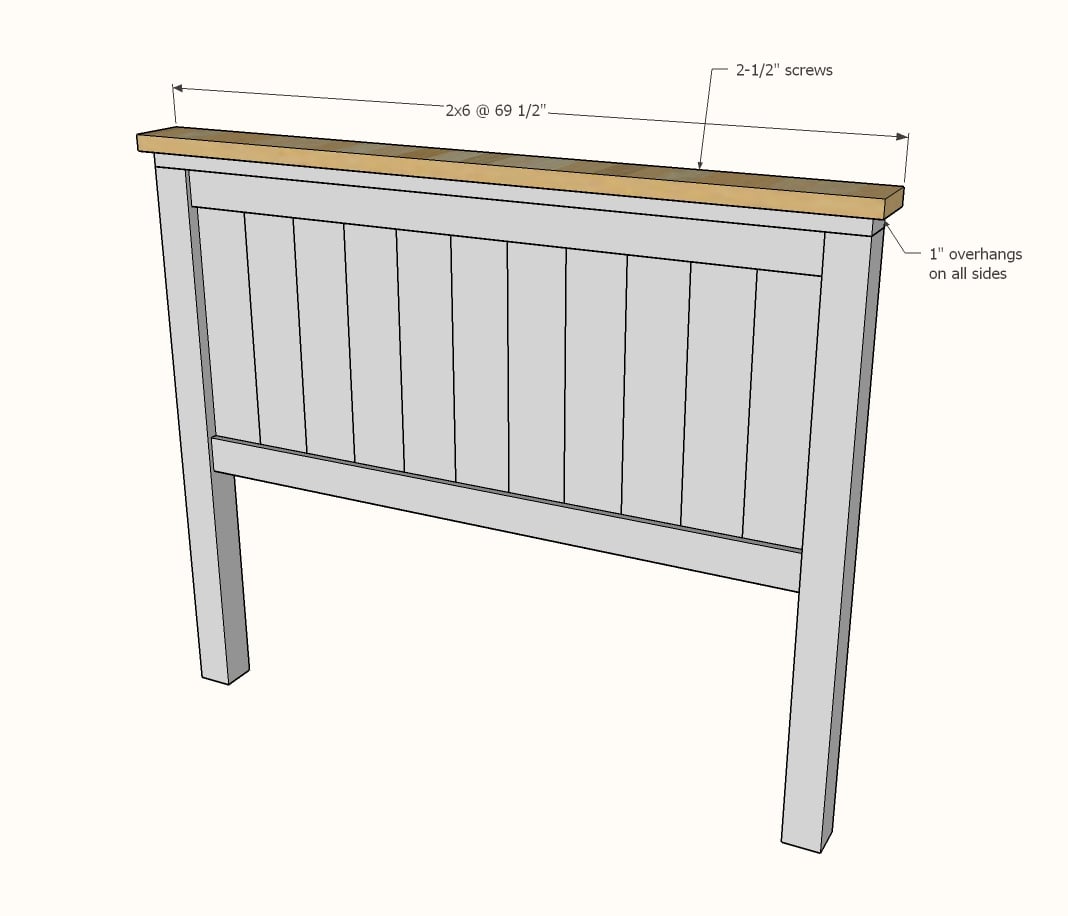

- 1 - 2x6 @ 69-1/2" - measure and cut to fit

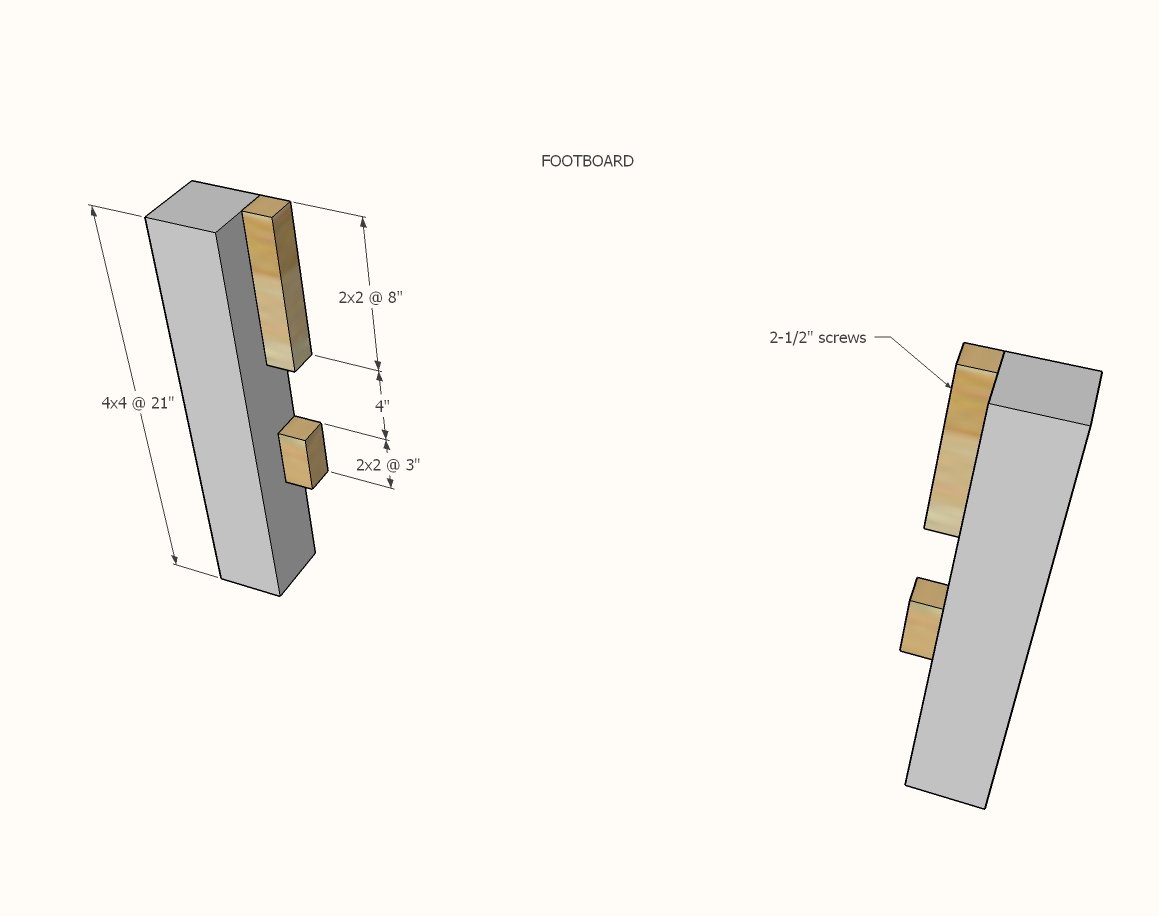

FOOTBOARD CUT LIST

- 2 - 4x4 @ 21"

- 2 - 2x2 @ 8"

- 2 - 2x2 @ 3"

- 11 - 1x6 @ 15"

- 2 - 1x4 @ about 60-1/2" - measure and cut to fit

- 1 - 2x4@ 67-1/2" - measure and cut to fit

- 1 - 2x6 @ 69-1/2" - measure and cut to fit

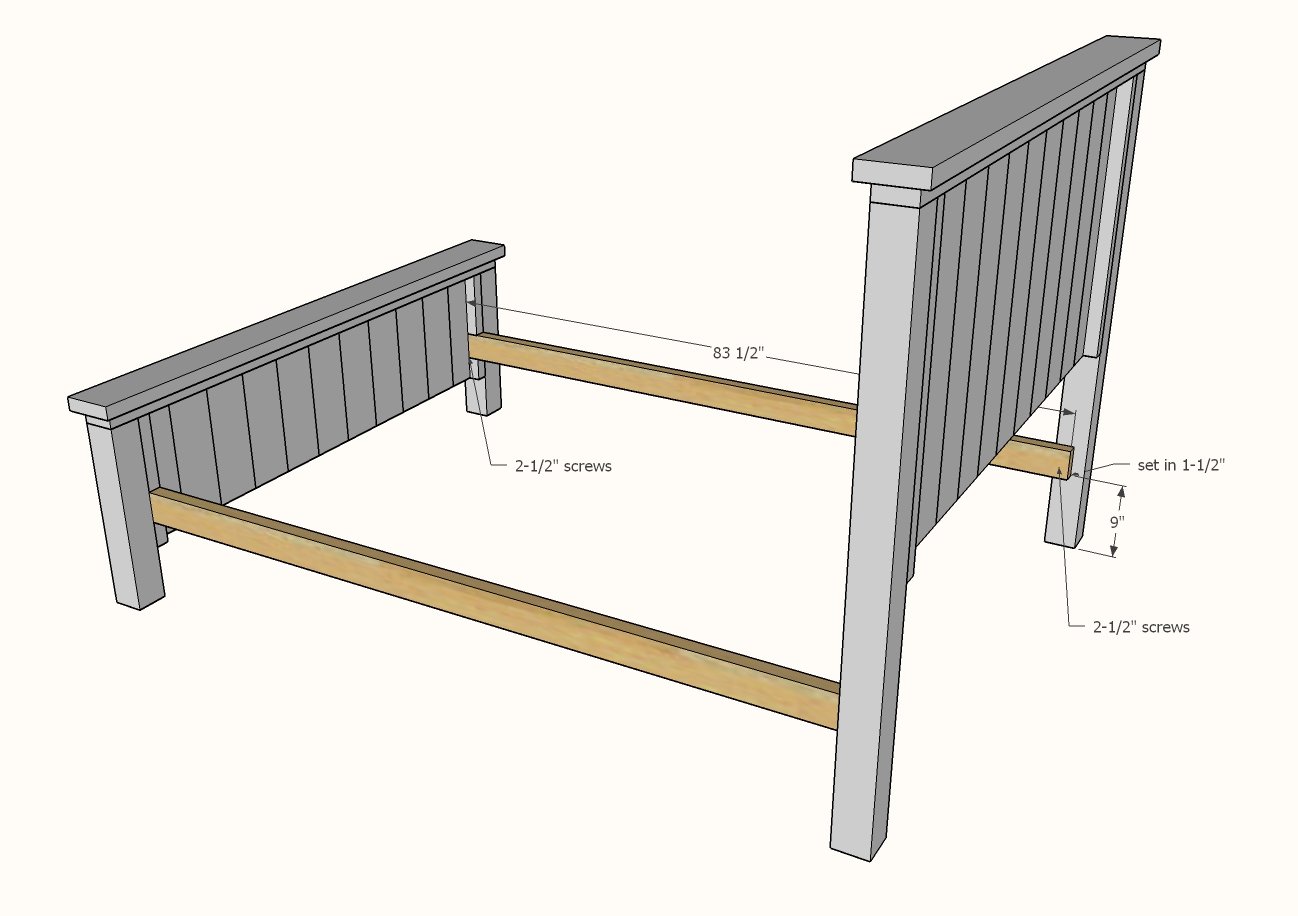

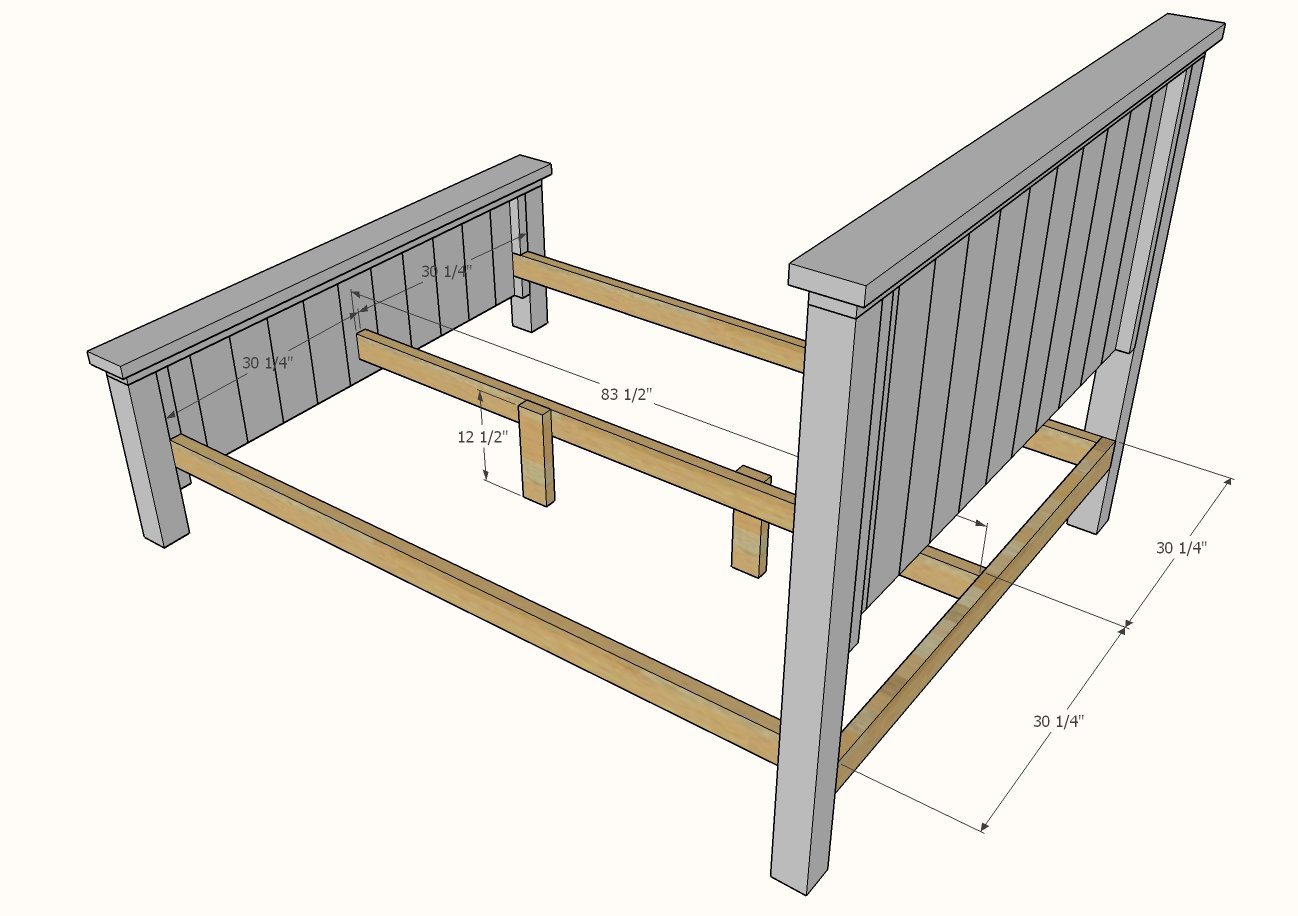

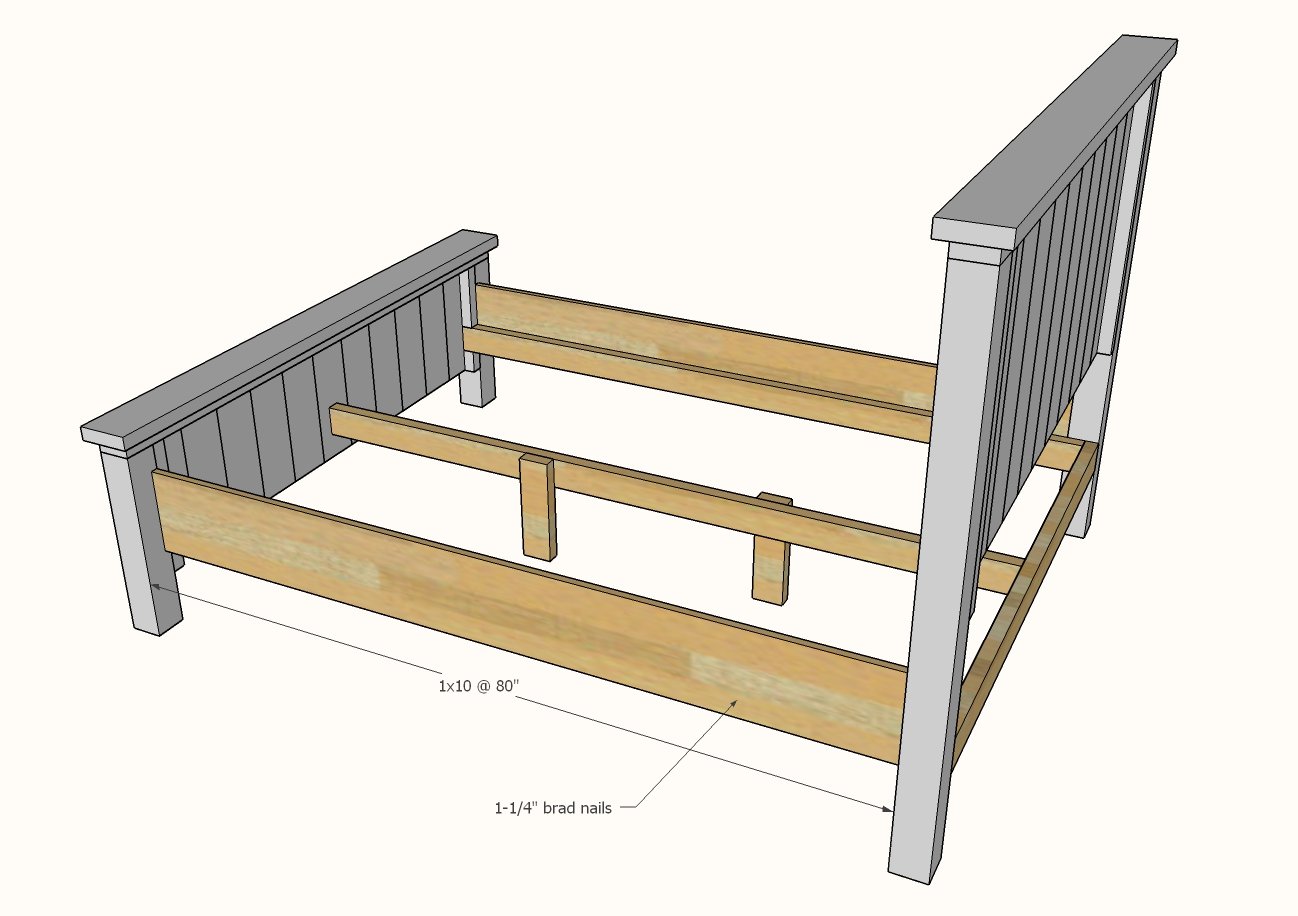

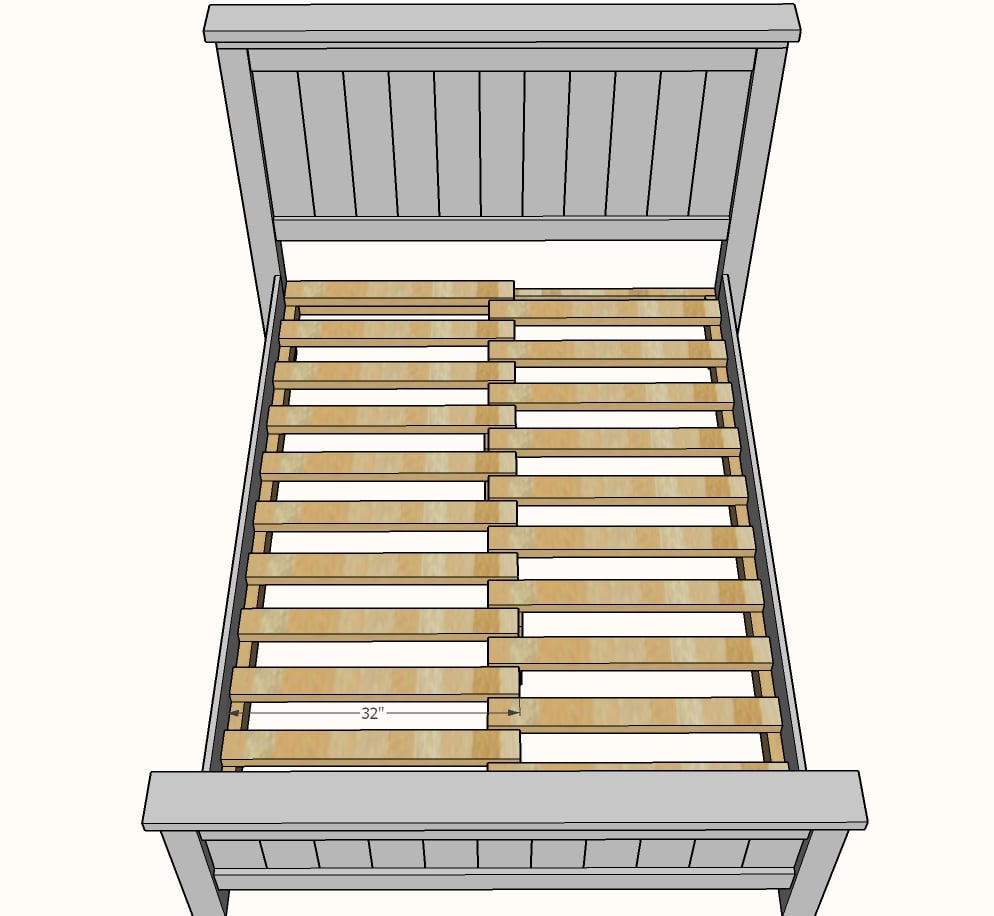

MATTRESS SUPPORT FRAME/SIDERAILS

- 3 - 2x4 @ 83-1/2"

- 1 - 2x4 @ 60-1/2"

- 2 - 2x4 @ 12-1/2"

- 2 - 1x10 @ 80"

- 20 - 2x4 @ 32" - can be as short as 30" if you need to burn up scraps

Cut all boards except as noted to measure and cut. We recommend using a compound miter saw for the straightest cuts, but you can also use a circular saw and a carpenter's square - just make sure your cut ends are nice and straight.

Instructions

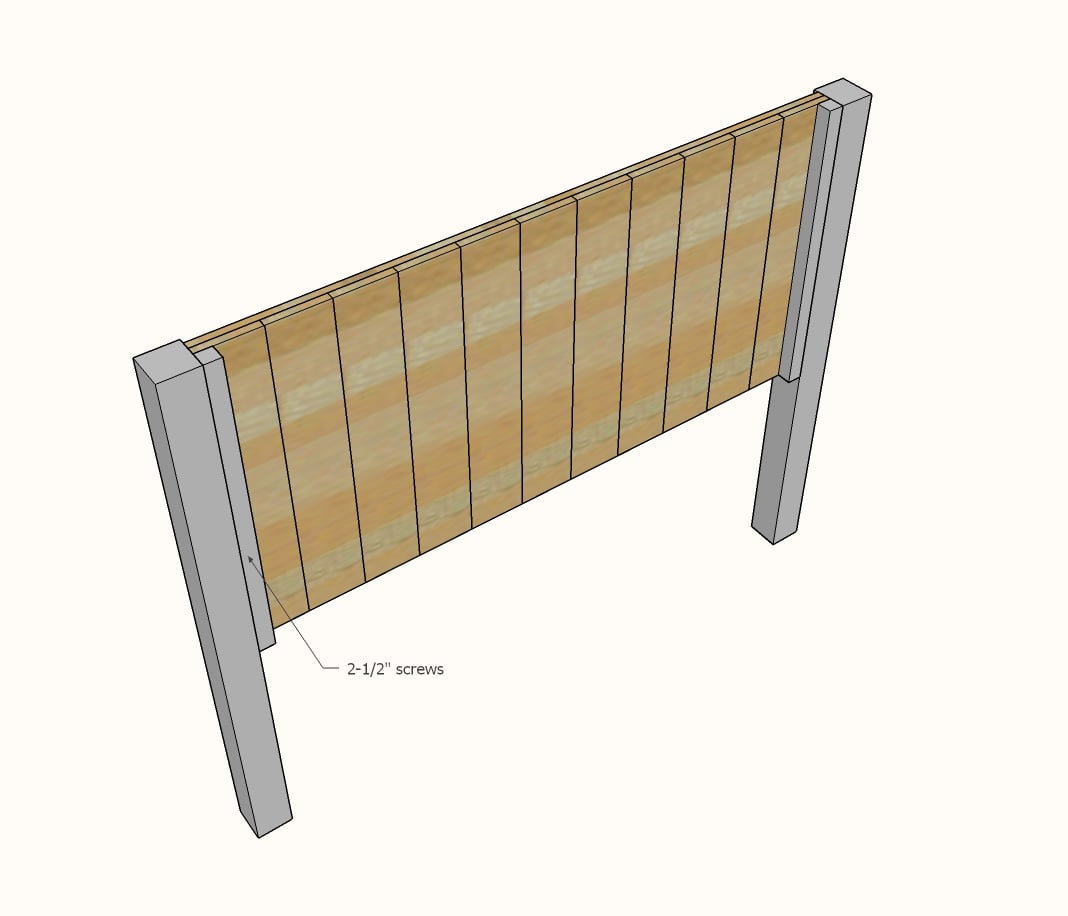

Step 1

Step 2

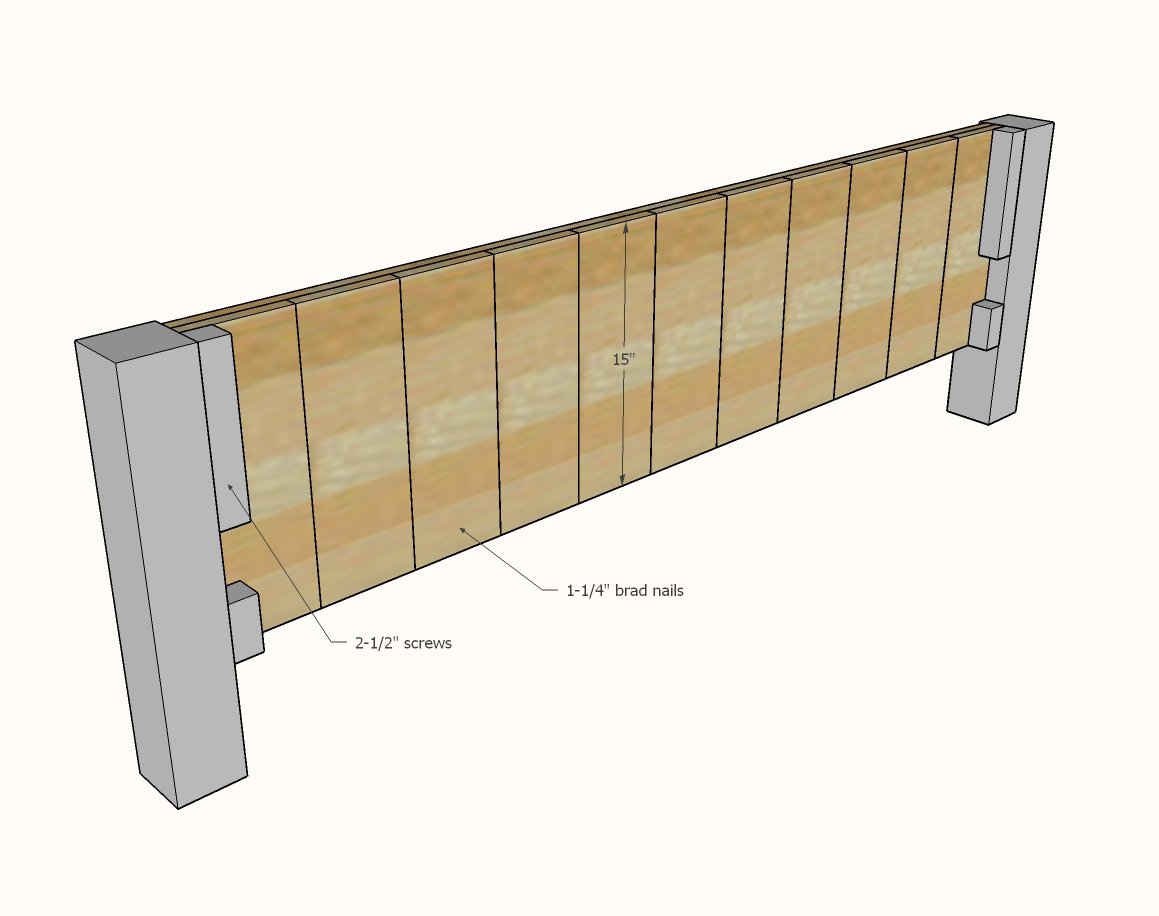

Layout the 30" 1x6 boards flat, side by side. Measure the overall width of all the 1x6 boards. Cut two 1x4s to this measurement.

Nail the 1x6 boards with glue to the 1x4s. Apply glue between the 1x6 boards as you go.

Make sure the panel is built square by measuring opposite diagonals (outside top corner of 1x4 to outside bottom corner of opposite 1x4) and adjusting so the opposite diagonals match.

Comments

wesleyjack

Thu, 01/12/2012 - 13:17

kerg jig

Can the kreg jig be used to make the actual frame portion or is that not advised

Erika (not verified)

Wed, 02/08/2012 - 20:44

Bed frame Question

What is the measurement between the top of the side rails and the bottom of the headboard?

If you've already answered this, I'm sorry-I did look through all the plans, honest :)

bhn5001

Wed, 02/15/2012 - 07:45

Really cool, but I have a few questions

How precisely are we supposed to attach the posts in step 2? We literally just drill into the section of the head/footboard where it is three boards thick? Do we then use wood putty to cover up where the screws are? How do we make sure the screws don't go into the (4) nails which were put in in previous steps?

Also, how are we supposed to attach the frame to the footboard.

Are there more detailed plans available via google sketchup?

This blog is awesome, its really cool to see all these detailed plans and people's stories... keep up the great work all and thank you very much!

Brad

Puddles872 (not verified)

Wed, 02/29/2012 - 16:38

For folks needing to elevate their mattress

Love this bed design but wondered how to modify so the top of the mattress would not be lying flat but rather elevated 2-3" higher than the foot of the mattress. My husband has GERD and this is what his doctor recommends and how we have our bed presently. Thanks Ana for your wonderful designs!

Rachelbirri

Fri, 03/02/2012 - 06:08

I have a box spring

I hope this question hasn't already been answered through other comments. I am getting ready to start this project but we do have a box spring for our mattress, so how does this need to be modified to work with that?

claydowling

Fri, 03/02/2012 - 06:27

Modifying for height

If you have a box spring, or anything else than changes the height, you can compensate by moving the support rails up or down appropriately. The best solution is to figure out how high you want the top of the bed to be. Then measure the thickness of the stack you're going to be sleeping on, i.e. box spring, mattress, futon. Subtract the height of the mattress stack from the desired bed height, and that's where the top of the support slats should be.

The height that I might find comfortable for a bed is very different than the height my mother in law would like, since we have a twelve inch difference in height.

Myself, I really like to be able to sit with my feet on the floor at the edge of the bed. Can't do that with my current bed arrangement, but that's what I really like for bed height.

Guest (not verified)

Sun, 03/04/2012 - 14:07

Farmhouse King Bed with Split Box Spring

Ana, my wife just turned me on to your web site and she sold me on building this beautiful farmhouse bed. I will be building it in king but i am trying to figure out how to use it with the split box spring that i currently have. I saw your design for a single box spring in queen, how would i modify this to fit our needs. Thanks much in advance, cant wait to start building.

Katerina (not verified)

Thu, 03/08/2012 - 04:42

Using screws instead of nails

Hi there! I have never built anything like this but am going to give it a shot this weekend. For step one I wondering if I can use screws instead of nails? I do not have a nail gun, and my boyfriend pointed out that it is easier to take things apart that are make with screws if a mistake is made. As I am BRAND NEW to this kind of stuff I would really appreciate advice! Thanks so much, and thanks to the talented Ana for sharing this site with us!! It's amazing!

claydowling

Thu, 03/08/2012 - 04:54

If I had a hammer

I'd hammer in the morning, and get a lot of complaints from my wife about all the racket. Also, she doesn't like it when I sing Woodie Guthrie songs.

But seriously, you don't need an air nailer to use nails. A good 16oz hammer and a nail set will work just fine. Just avoid the temptation to think "I'm only a girl, I should buy a small hammer." The bigger the hammer, the easier the nails are to drive. A 12oz hammer for driving nails will make you sore and mad. Also look for one with a smooth face on the hammer, rather than a waffle face.

You should also pick up nail sets, which are used to drive the nail heads below the surface.

Katerina (not verified)

Sat, 03/17/2012 - 16:37

Thanks for your advice. I

Thanks for your advice. I decided to go ahead and pick up a hammer and I've had great success! My bed is almost finished, I just need to paint it. Thanks for your encouragment :)

MarcelleG (not verified)

Thu, 04/05/2012 - 14:57

Wall paint color

I know this is random, but do you know what is the name of the wall paint color? I absolutely love it!

Guest (not verified)

Fri, 04/06/2012 - 10:55

very good

im need how to make mdf bed frame

Regina (not verified)

Sun, 04/22/2012 - 16:39

Farmhouse Queen Plans

I plan on trying this plan for my guest room. I have one question. How easy is this bed frame to break down in order to move after being built ? I tend to redecorate often. I dont want to have to unscrew a lot of screws just to move to another room.

Darcie (not verified)

Fri, 05/11/2012 - 14:01

Jumping in with both feet!!

Hey Ana,

My husband and I are celebrating our 23rd wedding anniversary next weekend and I've decided that I'm going to make this bed as my gift to him. (Yep, I'm a last minute kind of person!) We've gone back and forth from Queen to King size beds and have never had a nice head/foot board.

I just ventured to my local orange store armed with my pick list. (I found 4 x 4 doug-fir posts with no problem here in Utah). For years now I've been a wanna-be furniture builder! I'm going to do this!

I'm super stoked but feeling a bit nervous too. My husband and I absolutely love the natural grain and textures in wood and I know he's going to love this bed.

I would have never dared this type of venture without your support Ana.

Thank you so much for sharing your knowledge with all of us wanna-bee's!!!

God gives us talents to share and promises to bless us with more talents if we do....you much be a Goddess by now with all of the sharing you've done!

Gratefully yours,

Darcie in Utah

Darcie (not verified)

Fri, 05/18/2012 - 10:20

Thank Heaven for trim molding!!!

OK so several of you have mentioned that this is your first real woodworking project....if so I can't be the only one having problems.

First of all, how the heck to I keep everything square? Ive tried the 3 4 5 method, measured criss-cross from corner to corner, and even used a small square when attaching each board on the headboard & foot board. Everything still ended up not being exactly lined up and it's driving me crazy! Ive taken apart and redone the different components on this thing several times now.

Ive added trim and it hides some of the unsightly mishaps. but now I'm having a heck of a time getting the lag screws drilled straight from the 4 x 4's into the 3-layered panel pieces!

Yes, I've already admitted that this is my first real project but dang-it I want this to look good!

I know that Ana's knowledge could never be transposed into text onto this project plan but surely someone can shed some light on getting nice straight drilled holes! I didn't think this would be so awkward. They keep ending up slightly angled and coming out the middle of my panel. Also, the 4 x 4 isn't cinching up tightly against the panel...??

Nick B (not verified)

Mon, 05/28/2012 - 21:59

Had to modify the plans

Had to modify the plans slightly for my purposes. Being military, I move around a lot. Instead of 4x4s, I used 2 2x4s for the posts, but I cut a space 8" up and left room for the side rail to fit in to the footboard and rest flush with the outside of the post. Same with the posts of the headboard. The side rails have a 2x2 cleat running along the entire length, which cuts out the joists for slats- and if need be I can add slats later, so the box-spring fits snug between the rails. The side rails are fastened to the headboard and footboard with 5/16" lag bolts, and all that is needed to disassemble is to remove the 4 bolts and the bed comes apart like a puzzle into two siderails, headboard, and footboard. Your plans are always a great starting point for me, and the way they are put together leaves plenty of room for modification. Thanks!

Trisha Johnson (not verified)

Fri, 06/15/2012 - 15:24

Farmhouse Queen Plans

I was wondering what kind of paint you used to paint the bed? We have painted furniture before, however, the paint we used yellowed.

Angel Rose

Tue, 07/03/2012 - 15:34

attatching posts

someone who has made this already may be able to help.

How do I make sure my screws go through my post and hit the 3/4 inch board on the other side? I may be making a silly mistake, but i have tried measuring twice and have missed the boards and ruined my posts twice . . . . . was feeling so accomplished up until this point. Any advice would help.

Byron Young (not verified)

Thu, 09/27/2012 - 11:44

Only Screw at Sandwiched Sections

From how I read the instructions (and how I did mine) you are only supposed to screw the 4 1/2 screws into the posts where the boards are sandwiched 3 thick, not in the middle sections where the 4x4 meets with your 1x8 (or 3/4 inch board, as you say). I put 3 screws to the top section that is sandwiched and 3 screws to the bottom section that is sandwiched, making a total of 6 screws per 4x4 post. If everything is square, there won't be a gap (or at least a very minimal one) in the middle section where your 4x4 post meets the 1x8 board.

Hope that helps.

Nate (not verified)

Tue, 07/31/2012 - 14:52

How to attach side rails to foot board

Ana, thinking about building this for my wife, but I'm confused about how the side rails attach to the foot board. I see that for the head board, they just slide in on the inside of the 4x4s under the paneling. For the foot board, do they butt up against the paneling on the inside? Is there enough 4x4 to grab inside the paneling? Thanks!

Calyn (not verified)

Fri, 08/10/2012 - 14:04

Matching furniture

Just was wondering if you'd thought of doing plans for a matching dresser and chest of drawers? This bed plan is fabulous and will be perfect for the look of my master bedroom!

Lisa Bruchac (not verified)

Thu, 08/16/2012 - 11:30

Hi Ana, this is an amazing

Hi Ana, this is an amazing site.....I am so grateful I found you....I have one question: is this bed a platform bed or can you use box springs and mattress? Thank you...

Pammylaine

Wed, 08/29/2012 - 12:12

Quick Question

Should I use Pocket holes to attach the legs to the panels? We recently built a bed for my son so I'm really into using the Kreg Jig if possible.

Byron Young (not verified)

Wed, 09/19/2012 - 17:33

Post (4x4) Problem

Ana (or whoever might can help):

I'm having trouble when screwing my 4x4 posts to the panels. I'm getting a gap between them, and it might not be extremely noticeable, but I can actually see the screw in the gap. I am putting one end of the panel against a door, then I'm using a drill and pushing from the outside of the post into the panel. I thought by having a backstop and putting pressure against the post while drilling, I would avoid making a gap. I'm fairly certain I'm doing something wrong.

Any help or suggestions would be greatly appreciated!

USMCamp0811 (not verified)

Sat, 10/13/2012 - 06:55

Not sure exactly where the

Not sure exactly where the gap is but sounds like maybe your panels were not a full 6". I had a similar issue and just used some 1x2s to bridge the gap. If its not that big of a gap then you may also be able to use some wood filler to fill it. Hope that helped..

ONI (not verified)

Wed, 09/19/2012 - 20:37

Curious when screwing in post

Curious when screwing in post for legs do you drill 6 screws I'm line going down or in groups of 2s and does it matter ... Never built anything like this and willing to try can't find a twin bed I like for my girls

tjroll123 (not verified)

Fri, 09/28/2012 - 14:40

We are working on this bed

We are working on this bed right now. We have a king so we went with 1x8 (which are really only 7 1/4) but did 11 panels. It will work out perfectly because you need a little extra space for the side rails to go on the inside of the headboard. I am thinking of getting some side rail brackets so it makes taking apart and putting back together easier (although I never plan on moving but we will be replacing our carpet sometime in the near future). We are also making our headboard just a few inches shorter so it will look better under our window and making the footboard a little taller so the top of the footboard is above the mattress.

Jarod (not verified)

Wed, 10/10/2012 - 16:59

Building this was easy!

My wife found this and had me go to work, hasn't been to hard, although the more precision and high quality wood you put into it the better the result. Looking forward to finishing soon, can't wait to start the next project

Terra (not verified)

Fri, 10/12/2012 - 17:44

How to attach bed rails

Hi! We are in the midst of building the king size bed and we are at a total loss. How do you attach the bed rails to the 4x4 posts? The actual pictures we saw, had the rails perpendicular to the 4x4 posts. How in the world did you do that? We want to finish this tomorrow so there is no time to order specialized products.

We are using slats because we do not have a box spring.

Suggestions? Attach to the inside of the post instead? Help... Pretty please.. and thank you for the great site!

Monica P. (not verified)

Tue, 11/06/2012 - 07:51

I'm no expert, but I think if

I'm no expert, but I think if you attach the rails to the inside of the post, your box spring (if you are using one) would not fit properly. The only thing I can think is to cut out space from the post large enough to nestle the siderail into, or (like you stated you don't want) get some hardware. I think you should order the hardware, it's easy to attach and it make your bed mobile if necessary.

USMCamp0811 (not verified)

Sat, 10/13/2012 - 06:48

2x4s for the frame

Would I lose any strength if I used 2x4s to build the bed frame for the mattress to sit on? I originally had not intended on using the frame as I have a box spring; however when I started to look and see how it was going to look height wise I am changing my mind. My mattress as is sits 21" high w/ boxspring just sitting on the floor. The footboard is only 24" high. If I do away with the boxspring and build a frame, I can gain some extra space. Basically I don't want the mattress towering over the footboard.

My solution was to use some extra 2x4s I have laying around and build a frame similar to above. I've got a pretty heavy memory foam mattress that I want to ensure has proper support and is not towering over my footboard.

What do y'all think?

Samamantha landsberg (not verified)

Wed, 10/17/2012 - 11:22

LOVE IT!!!

i found your site here and love everything about it.. it has really inspired me to play with wood..lol (not that way..hehe) i'm very crafty, but wasnt so sure about building.. my husdband had a customer that owned a mill. so i wrote my list and gave it to him for this bed.. and what i got back was absolutly beautiful raw red pine... Oh my is it beautiful.. it has been 6 months now it is planed and dried finally and this week we are working on building it.. I do have one question i have serched for as you stated ubove with using a box spring.. but i can't find what i need.. i have all the wood to build the middle but would it still work with using a box spring???

also if i knew how to post pictures i would lol with the scrap wood I built a potting bench always wanted one and i serched on here for one and was so excited although with no measurements, my husdband told me make a blue print.. so i did and you should see it.. absolutly beautiful... thanks for the site and look forward to hearing from you...

Monica P. (not verified)

Tue, 11/06/2012 - 07:42

Pocket Holes vs. 4.15 wood screws?

I have a question for anyone that would be kind enough to answer. I am in the process of making the queen farmhouse bed. I read through all the brags posts and plans and I believe I have made the right tweaks to get the bed will perfectly meet my needs.

There was a brag post that mentioned using pocket holes on the inside of the trim panels to screw into the post, I decided to use the pocket hole suggestion but to also use the 4.5 inch wood screws to screw into the panels from the post. I felt like that way I would have 2 screws going in both directions...so I would be covered. However, yesterday, I drilled pocket holes and used 2.5 inch pocket hole screws, two on each trim panel, for a total of 4 screws in each post. After I screwed them all in, my footboard felt STURDY. My question is: Am I okay just using the pocket holes? Or should I absolutely use the 4.5 inch woods screws through the posts?

My rationale is that I may be okay just using pocket holes screws, because the two screws in each panel, both penetrate the posts about 2 inches, whereas the original plan calls for 3 screws into the post, but would only penetrate the panel 1 inch per screws. So the inches penetrated by the pocket hole screws would be greater.

Any thoughts?

Thank you!

Ashlee (not verified)

Sun, 11/11/2012 - 19:35

King size plans?

Do you by any chance have plans for this bed, as a king size?

Wanda McLennan (not verified)

Mon, 11/12/2012 - 12:28

4x4 post

Can someone tell me what they used for the 4x4 post? I can only find pressure treated post. Any suggestions.

Flasinc (not verified)

Wed, 11/14/2012 - 16:42

4X 4

I too am having a hard time finding non-pressure treated 4x4's. Many comments say they paid $$ for fir or cedar. I have no options. I have called 5 lumberyards (forget the big box stores - they only have PT) and no one has any. I am in FL. I don't want to use 2 2x4's, but think I may have to. I have 2 panels waiting in my garage and my boys are getting inpatient as they want their new beds. I will try to call a few other places, but then will have to go with the 2 2x4's.

Rick R (not verified)

Tue, 11/27/2012 - 11:16

My Variations

I built this in King size and changes a few things. I made my posts 5 X 5 and raised the footboard to 31". I also wanted to have the ability to diassemble this so I flush mounteded the side rails to the front of the posts. Nice design. Thanks

Dave Peterson (not verified)

Sun, 12/02/2012 - 12:32

King size plans

Hi Ana! Can you provide me with the plans, cut list for the King size?

Thanks and love your style!!!

JulieH12 (not verified)

Sun, 12/16/2012 - 14:31

4x4's

I bought 4x4 cedar posts for $17/post at Lowes, but I found the 4x4 non treated pine for $8 each at Menards.

Brad D (not verified)

Fri, 12/28/2012 - 17:38

Box Spring

I love your site, I am a first time home buyer and am planning on trying a bunch of your plans. A couple of questions though. First, how do you know at what hight to attach the frame to the posts? Second, I don't have a box spring so I plan on building the frame. Does a piece of plywood go over the frame to form the box spring? Thank you so much for your help!

Charles Fogel (not verified)

Thu, 01/03/2013 - 21:27

Headboard panels not 7 1/2"

My headboard panels don't measure 7 1/2" as Ana warned and I'm not sure what she means about adding 1 by 2 trim. I'm a real newbie so I'm hoping somebody can explain in detail what she means by adding the trim on the headboard. Thanks in advance.

Charles Fogel (not verified)

Fri, 01/04/2013 - 20:26

Making the queen assembleable.

I did most of the work on the headboard today and found it to be rather heavy. I would like to make it so I could hang the frame on the head and baseboards or visa versa so we could easily disassemble the bed when we move. Has anybody done anything like that? Also should I attach the 4x4s to the headboard with screws in a vertical line or horizontal or what. Or maybe it doesn't matter. I'm pretty new to this. And thanks to Ana for her excellent blog and getting me going!

Charles Fogel (not verified)

Fri, 01/04/2013 - 20:32

Making the queen assembleable.

I did most of the work on the headboard today and found it to be rather heavy. I would like to make it so I could hang the frame on the head and baseboards or visa versa so we could easily disassemble the bed when we move. Has anybody done anything like that? Also should I attach the 4x4s to the headboard with screws in a vertical line or horizontal or what. Or maybe it doesn't matter. I'm pretty new to this. And thanks to Ana for her excellent blog and getting me going!

Charles Fogel (not verified)

Sat, 01/05/2013 - 12:22

Making the queen assembleable.

I did most of the work on the headboard today and found it to be rather heavy. I would like to make it so I could hang the frame on the head and baseboards or visa versa so we could easily disassemble the bed when we move. Has anybody done anything like that? Also should I attach the 4x4s to the headboard with screws in a vertical line or horizontal or what. Or maybe it doesn't matter. I'm pretty new to this. And thanks to Ana for her excellent blog and getting me going!

Charles Fogel (not verified)

Sat, 01/05/2013 - 12:24

oops

sorry for the repeated comments...

Katie Jackson (not verified)

Mon, 01/14/2013 - 12:29

Hello, How far is the bottom

Hello,

How far is the bottom of the mattress from the floor? I have a 12" thick mattress and don't want to make it too far off the ground.

Also, is there a way to make this to take apart for moving and storage? Perhaps with bolts connecting the siderails to the headboard and footboard?

Thanks so much! I can't wait to get started!

kenziedoll90

Thu, 01/31/2013 - 21:15

skipping a step

If I go ahead and get the wood pre-cut for the "cutlist" at the hardware store can I skip the circular saw?

bibbitbear89

Mon, 02/11/2013 - 07:46

I am looking for

I am looking for a dresser and a chest of drawers that match this bed. I have already found a night stand. Please help.

bibbitbear89

Wed, 02/13/2013 - 08:01

love this bed

Hi my name Bridgette Iam a newly single mom. I am looking for a dresser and a chest of drawers to match this bed i already found a night stand.

bibbitbear89

Wed, 02/13/2013 - 08:01

love this bed

Hi my name Bridgette Iam a newly single mom. I am looking for a dresser and a chest of drawers to match this bed i already found a night stand.