Lift Top Coffee Table

Instead of attaching the top to the coffee table base as done in the plans, the top is attached using a set of coffee table lift top hinges.

Instead of attaching the top to the coffee table base as done in the plans, the top is attached using a set of coffee table lift top hinges.

Worked on the bed over the summer at the same time I redid the floors. I built the side tables one at a time in case I needed to change anything for the second one. All in all these were fairly easy to build. Thanks Ana!

Changed the scale of the front panel and the window trim slightly. Added window boxes for a drink, toys and book storage.

I made this pantry to match some new kitchen cabinets that my friend ordered from lowes. He wanted me to make all of his cabinets but unfortunately I didn't have enough time, it was kind of one of those things hey I'm redoing my kitchen can you make this. This was all built and designed from a picture his wife found on pinterest with just the measurements for the space it needed to fit in.

Mon, 02/10/2014 - 10:25

Great job! We're planning a pantry build in the near future and yours is just lovely! I love the pull out drawers!

Mon, 02/10/2014 - 10:25

Great job! We're planning a pantry build in the near future and yours is just lovely! I love the pull out drawers!

Fri, 06/17/2016 - 18:39

HI -

My husband and I have been trying to find a DIY Pantry for our kitchen. We've looked everywhere and finally came across this! We love it and would like to try and build it. Do you have the plans available to share? I look forward to hearing back from you.

Fri, 11/27/2020 - 21:33

I tried the link for crafted perfection in attempt to get the plans for this. It led me back to this website. Is there ANY chance of getting the plans for this pantry PLEASE?

Thu, 12/24/2020 - 07:18

Where can I get the plans for this pantry -- Please advise.. Love your work..

Fri, 08/06/2021 - 14:55

Please send me the plans for the kitchen pantry!!

Wed, 09/01/2021 - 13:59

Okay, Ana, where are the Plans? You're killing me with this teaser! I'm not smart enough make something this great without serious plans like you usually produce. Help this old guy, please.

Wed, 03/23/2022 - 12:03

I would love to get these plans. We are in a new house and I need extra storage and this is perfect.

Thu, 08/11/2022 - 18:08

Hi Ana! Do you have plans? My daughter is moving and could always use more kitchen cabinets. She loves kitchen gadget everything!

I saw this table on wyrmwoodgaming.com but I wanted to see if I could make it myself. I did it all in Cherry and used Tung oil to finish it. I have two coats of Tung oil on there for a finish. In all I paid about $800 for the cherry and flat steel I used for the magnetic rails on the sides.

Michael Frerichs

Wed, 03/27/2024 - 06:31

Investing in a custom game table can really enhance your gaming experience. It's not just about having a cool-looking setup, but also about creating a space where you can fully immerse yourself in the game without any distractions. Speaking of which, I recently stumbled upon a non Gamstop casino on https://notgamstop.com/ which adds an interesting twist to the gaming experience. Check it out if you are a keen player like me and choosing only the best options for yourself.

My attempt at the murphy bar featured on this site. Still have to add the sash locks. Added pallet crossmembers at the back, an x in the leg, and a french cleat to mount to the wall.

Tue, 12/31/2019 - 11:49

This looks awesome! I want to help my friend build this for his kitchen. I've looked at the plans in the link & I'm wondering what modifications you made for the X pattern-- how much did it alter the material & cut list?

Would you please share your material & cut list for this?

Fri, 08/14/2020 - 09:28

I don't understand why I cannot find the material list or the instructions for this every link takes me back to the pictures

Wed, 12/08/2021 - 00:27

It is perfect wall management which is used it in small space

Sun, 01/29/2023 - 13:16

Are there plans for this? I'd love to make this. Thanks

Our take on the small garden shed. Ours is 4 1/2 by 7 feet. We used cedar fence pickets and 2x4 construction. Left over shingles from when our house was built. We are definitely not roofers or framers, also chasing around a 3 year old didn't make things easier. Turned out beautiful for what we want it for. Just rustic enough. Great intermediate project.

Mon, 11/30/2020 - 11:14

You did a great job, the 3 year olds add just the perfect amount of challenge to really appreciate a completed project!:)

We wanted a round table that would seat a full Monopoly game. To do this we needed about a 5' diameter tabletop. The base was made consistent with the plans.

A few tips on the base:

If you want to make a round tabletop, here is what I did (there may be better methods). Keep in mind this was for a ~60" diameter table, I was assuming that the perimeter arc pieces would be about 4.5" wide and that I would cut the inner circle at a 50" diameter.

Fri, 12/19/2014 - 07:13

Simply beautiful. Very impressed with this table top.

Tue, 01/13/2015 - 10:05

Can we get some better details on the instructions for this?

In reply to Better instructions? by odeeodum

Sat, 02/07/2015 - 16:52

I updated the instructions. Let me know if you have any more questions.

Sun, 03/08/2015 - 10:23

Hi, your table is beautiful! I was wondering if you had to increase the size of your base since your table top is 60". I'm going to be building a round one the same size and wanted to make sure it would be stable at the current size.

In reply to did you increase the base size by ILoveDIYing

Fri, 03/13/2015 - 20:36

The only modification I made to the base was the to the lengths of the 2x4 pieces that make up the "X" that sits between the base and the tabletop. In the plans, this "X" is made of (1) 32" piece and (2) 14.5" pieces. I believe I increased these to 36" and 16.5", respectively. Truthfully, I don't think this modification added much value.

I did some calculations and at a 60" diameter, it would've taken over 100 lbs placed at the edge of the table. This was also a function of the weight of the table. The heavier the table, the more stable it will be.

Tue, 03/31/2015 - 07:30

On your boarder pieces what angle did you cut the ends to and how did you lay the pieces out to route the diameters?

Sun, 04/05/2015 - 19:21

I want to put a concrete top on this base and increase the diameter to 72". Would I need to increase the size of the base to accommodate the larger and heavier top? Thank you

In reply to Increased base size? by Momma Gladden

Tue, 04/14/2015 - 20:20

It all depends on how much your tabletop weighs. I'm going to take a wild guess that your tabletop will weigh around 500 lbs (~28 sq. ft. at ~18 lbs/sq. ft.). For reference, I think my wood top weighed about 80 lbs. I will also assume the wood base weighs 50 lbs. Using these assumptions, the result is a worst-case scenario (weight placed at edge of table, tipping between two table legs) of tipping at 300 lbs. The lighter the tabletop, the less stable it will be. Since your concrete table is likely to weigh a lot more than my wood top, it will be a lot more stable.

That addresses the design and assumes none of the wood or connections (screws) fail under the increased load (weight of concrete). I can't speak very confident to this aspect. Though I can venture a guess. I will guess that it will be stable under no load, but there will increased loads when under uneven stress (i.e. somebody leaning on one side of the table). Honestly, I don't know how valuable any further speculation would be.

Tue, 09/06/2016 - 08:14

Can the pedestal hold a 66"- 72" top? I've been searching for a table that seats 6 comfortably with an occasional squeeze for 8. I think a 60" would work but my husband thinks 72". We are struggling to find exactly what we want and are now investigating DIYs . This is a beautiful table!!

In reply to 72" version by X3cougsp

Wed, 10/05/2016 - 17:16

This is a conversation that we had in our house as well. My personal opinion is that 60" is big enough for 6 people and good enough for 8 people. What we did to "dry run" it was I cut a board to 72" and set it up at table height and we sat at oppposite ends of the board. I asked my wife if it was too big and we both agreed that not only would really shrink the room, but it also was too big for regular use. We currently have 6 chairs around this on a regular basis. As for the stability of the table itself, you may want to increase the width of the base. I say this because 74 lbs at the edge of the table (in between legs) will cause the table to tip, which is probably a force that will be exceeded by someone leaning on it.

In reply to curved piece how to cut them by jcatanz740

Sun, 12/25/2016 - 07:11

I've put a new pic up that shows my setup while cutting the perimeter pieces. What's not clear is that I screwed the pieces to my workbench from the bottom.

Thu, 12/22/2016 - 20:58

I used the jig that I made the large circle but made a couple new radii. The inner edge was the round piece radius minus half of the bit diameter. The other radius is as wide as you want to make it.

I fixed this jig to my work bench and set it up so that I would be cutting each piece identically. I have a picture that I'll add that shows it better than I can explain it.

Mon, 01/09/2017 - 07:36

On your boarder pieces what angle did you cut the ends to make them fit?

In reply to Boarder pieces by Omally83

Sat, 01/21/2017 - 07:46

I believe my approach was that I cut the 2x8s to the length that would produce the arc length I was looking for. So basically the outer edge was going to (if my jig did its job) be exactly as long as I needed it to be. With that in mind, I used a piece of yarn tied to the pivot point on the jig that I was using and used that to tell me where I needed to make the cut.

Otherwise, I could've used trig to figure it out but I was all angled out by that point. With 8 border pieces they should each cover 45 degrees (360/8) and the other two angles should be equal ((180 - 45))/2=67.5) resulting in a 67.5 degree angle. The trouble in using that method is it doesn't account for all the little screw-ups that may have thrown off certain measurements. Plus, the yarn-thing was pretty easy.

In reply to I love this is this by Mdenton728

Sat, 02/17/2018 - 08:34

Do you mean extend like adding a leaf?

Sat, 01/23/2021 - 14:17

We made the table base for a 60" solid walnut top (used the wider measurements). When people get up from the table, my husband thinks the base twists when they push off. Has anyone else noticed this or have a suggestion on how to make the table not twist? Thanks, Sue

Couldn't be more thrilled with how these turned out. Plans were a cinch.

Last week we hosted a reception for our son’s wedding. We built 8 benches and 2 banquet tables over the course of 3 weekends.

The banquet tables are 30” x 8’ and are constructed from 2x4, 2x2 and ½” plywood, with some angle brackets at each leg for extra strength. We used the 2x2 for the tabletop apron/frame, attached leg assemblies made from 2x4 with some 1x3 furring strips for stringers, and topped the tables with ½” plywood. Hubby and I put these together in an afternoon. The tables were left unfinished because they were covered completely with tablecloths.

The benches are 42” long, 14” wide and 18” high. These were built from 1x3 furring strips for the bench top/frames and 2x4 for the legs. The bench tops were assembled first, then we attached the 2x4 legs to the frames at the corners, with a 5th leg in the center for stability. This was a fun “mom & daughter” project for me and the bride, and we got the 8 benches built in one weekend and the finishing done the next.

The bench legs are painted (1 coat primer and 1 coat paint + primer). The seats are topped with a clever combination of batting, fleece fabric and tulle ribbon ties, to create an upholstered look. The fleece fabric will be re-purposed into some pillows and a memory quilt.

The head table is our ‘almost farmhouse’ table with 2 of the modified Harriet chairs for the bride and groom.

The newlyweds plan on re-using some of the benches for the dining set in their new place. We’ll also be disassembling the banquet tables and re-using the wood to make them some more furniture, including a dining table to go with.

The wedding and reception was small and intimate and turned out beautifully. We were thrilled to put this together for our son and his wonderful bride!

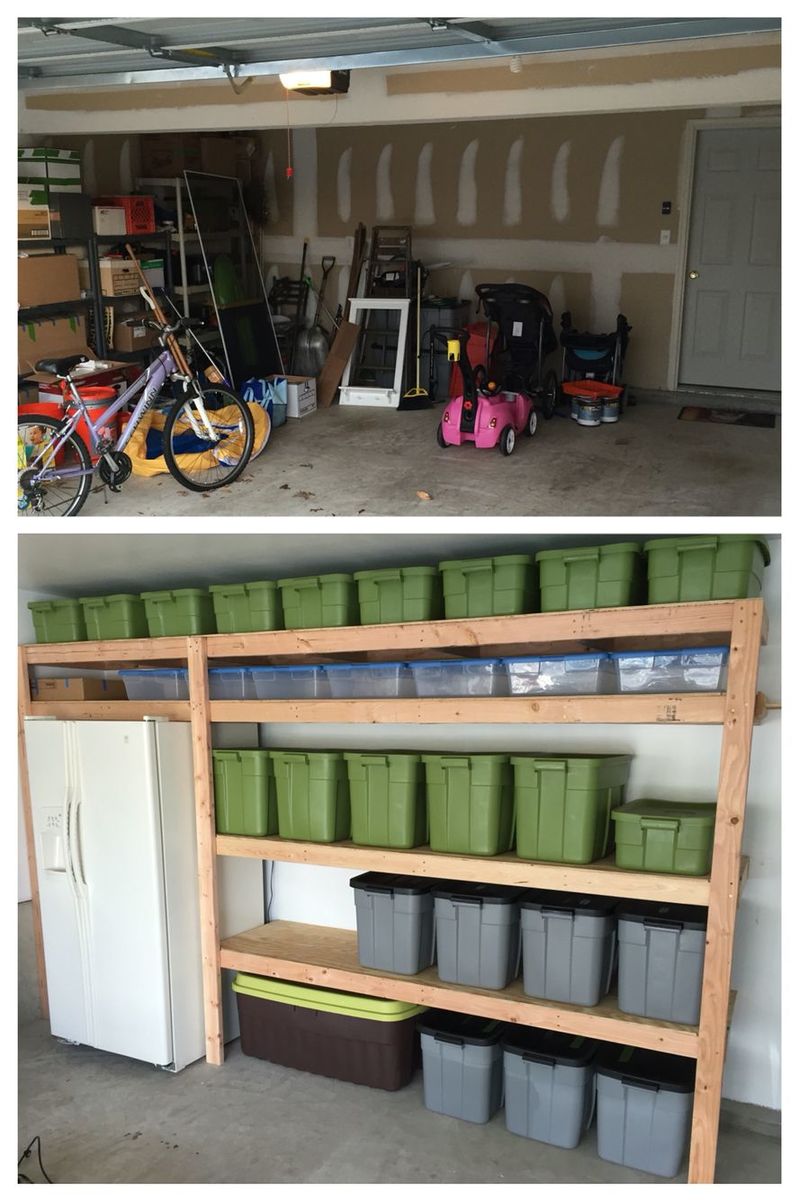

Easy to build, easy to customize, perfect for totes

I made a couple of additions/modifications

I also made a couple of side tables and foot stools for the chairs. A total of four chairs, two tables and two foot stools for the deck set.

We needed a couple of sturdy step stools for the bathrooms. My boys are not tall enough to reach the sink for hand washing and teeth brushing. Wally wanted $8 for a plastic thing. So I headed to the big orange store and bought a few 2X4's. $12 for both stools, plus the paint and screws which I already had.

I used the plans from the Skipper's Stool for some of my cuts. But I used 3-2X4 pieces for the top and shortened the legs to 10 inches. I was going to put on the side stretchers but it was super sturdy with the pocket holes and 2.5 inch pocket hole screws. So I left them off. A few coats of paint and they are good to go. Two of my boys can stand on one so that makes them a hit.

Cabin bed made into a barn for a 3 year old birthday boy! He. Was. Pumped!

This was my first project. It took me a weekend to build and prime. Since I chose to use a crackle finish, waiting time between coats extended the total time to one full week. My husband and I were supposed to make this hutch together, but I became obsessed and did most of it alone! I adjusted the size a bit to make it larger, so I could fit big pieces on shelves and in cabinets. Thanks for the plan Ana!!

Fri, 04/13/2012 - 14:47

Wow, this is sooo beautiful! The finish is just awesome. My Hubby hates to paint, and he saw this multi-step finish and said you must have the patience of a saint! :) Congrats on such a stunning first project!

Mon, 10/01/2012 - 23:33

Very Nice! What did you do to make it "bigger"...did you make it deeper or wider? Just curious, because I would like to try and make a bigger version as well. Did you still cut the shelves on each side at a 45 degree angle? Thanks!

We really enjoyed building this playhouse swing set for our kids. We have a decent slope to our backyard, so we needed to sink our posts, which required a bit more work thank Ana's plans. We also used a real window (my dad just happened to have in his garage) instead of the 3 open aired windows Ana's plans called for. Inside we built a fold under table, shelf, and a chalkboard for thier entertainment.

This is a plan that My 16 year old son chose to do for a project to fulfill a goal to learn some woodworking skills during our unexpected downtime from School.

Mom is thrilled with the new space.

He adjusted different sizes based on what lumber we already had. He used 1x7’s and routed a 45deg on the edges to give the tongue and groove look. Posts are 4x5 and top railing is 2x7.

Sun, 04/19/2020 - 17:42

Amazing, what a fine young man you are raising!!

These chairs were easy to build, although I modified Ana's plans a little bit. I opted for solid wood 2x2s for the legs (I wanted it to be sturdier), and a solid seat instead of a slatted one. I notched out the back of the seat so it would fit flush against the back legs. Because of my modifications, my chair was just a couple bucks more.

Also, I was so excited to find solid wood balusters for the chair legs - they're not only better quality, but cheaper than furring strips!

Check out my blog link for a complete play-by-play!

Mon, 07/23/2012 - 08:25

Nice. I like the solid seat. Much easier to keep clean from kid grime.

Built this over the weekend for my girlfriends sister. It was a great project and the whole family was able to work together on it, sanding and waterproofing it before assembling. The loveseat plans need a little tweaking. We ran ran the slats the same direction as the chair plans call for so we added a middle support for extra stability. We also pitched the seating down towards the back by 5* to make a more natural sitting position.

We used the shoe dresser instructions with some modifications to make it longer

Had a great time building this!!! Thanks for the plans!

Comments

ghozt21

Sat, 08/01/2020 - 09:06

Awesome, looks great!

Awesome, looks great!

Twheat91

Fri, 08/21/2020 - 23:38

Looks wonderful, love the…

Looks wonderful, love the finish. What kind of stain did you use?

Ana White Admin

Mon, 09/07/2020 - 20:23

Sweet!

Thank you for sharing, it looks amazing!

godmaire

Wed, 09/30/2020 - 19:59

I love this table. It is…

I love this table. It is just what l have been looking for. Is there any instructions. I would love to make this.

thanks

peggy