DIY Sofa - Storage Sectional

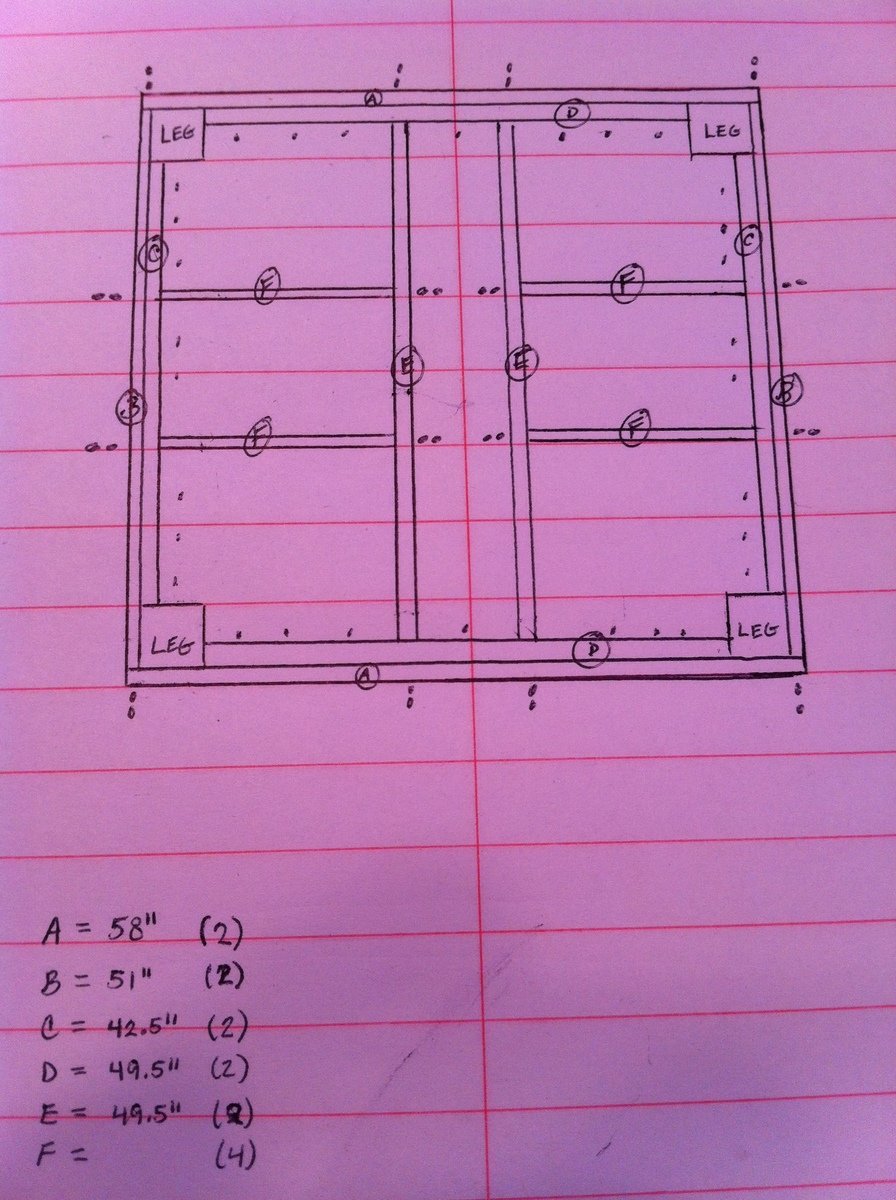

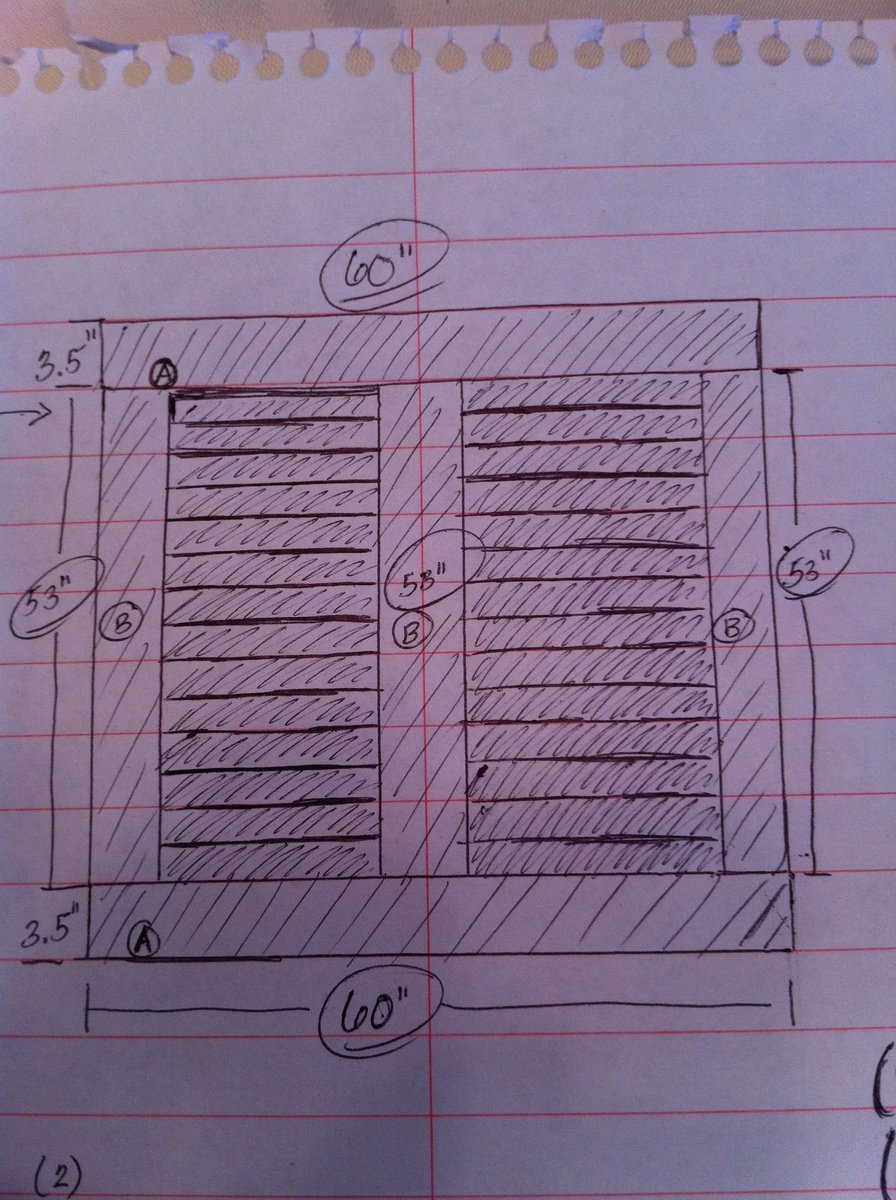

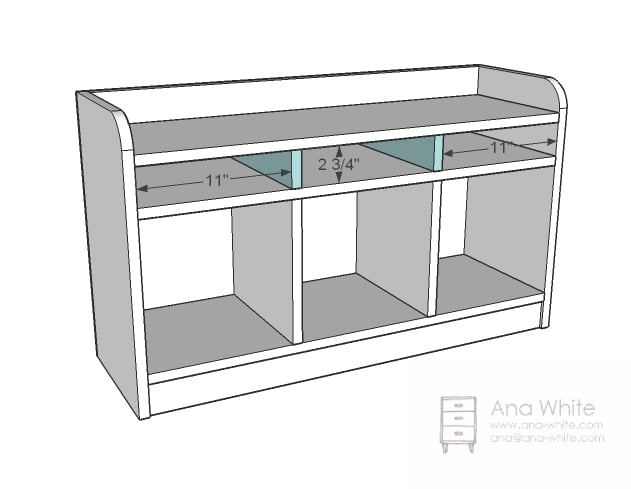

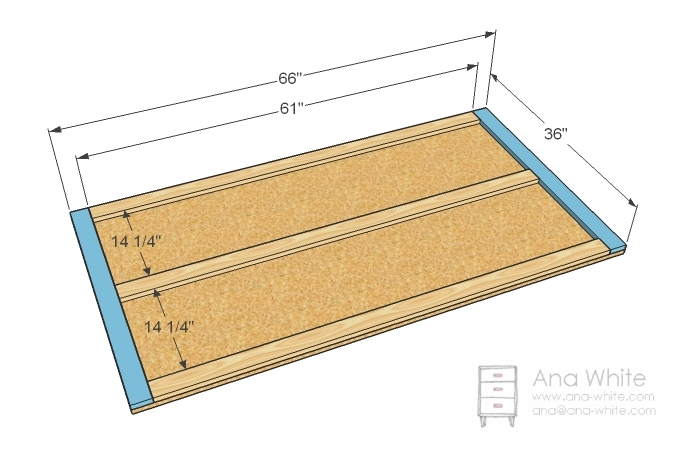

Basically I took Ana's plan and tweaked it to create a diy sofa, a love seat, and a corner piece to make a sectional. All 3 pieces have the same basic design and function (they all have a storage compartment), although the corner piece, because of its placement and the thickness of the seating cushions, doesn't open unless the couch is opened first. We purchased custom cut, 6" thick foam cushions for the seats (we bought the XL-38 foam from https://www.buyfoam.com/, but if we had to do it again, we'd go with the XL-28 as the 38 is VERY firm). We also used upholstery fabric instead of a paint drop-cloth to cover the couches. The foam and upholstery fabric upped the overall cost significantly. Other changes from Ana's plan, I used 15/32" OSB because the 1/4" plywood just felt too flimsy (I'm a large guy). I also added I bolts to the underside of the seat before the foam and upholstery so I could add a stress relief rope to prevent the kids from opening the top and dropping it and ripping out the hinges. I used piano hinges as they seemed to me to provide the most support. Finally, I ended up using 1x2s for the base trim since I couldn't find any 2x2s that were straight and finish-ready, then I added router detailing to provide some visual interest. I used 3" pieces of 4x6 for the feet and added matching router detail. Additionally, I used T-Nuts and bolts to make the feet and base trim completely removable.

Comments

spiceylg

Fri, 08/10/2012 - 12:53

WOW!

That's impressive. Great job!

vic b

Fri, 08/10/2012 - 13:34

wow

wow

kaytrishjr

Mon, 08/20/2012 - 13:10

I'm speechless!

Great Job!

masmith38

Fri, 10/23/2015 - 11:11

Awesome

Love this! Totally want to think hard about doing this instead of buying when time for a new couch comes. Job well done, and the storage is a total plus.

Chased

Sun, 05/15/2016 - 21:15

Plans

Where can I find the plans to this or the cut list

mikeyb

Mon, 10/03/2016 - 18:11

cost

Awsome job!!! question? is that a typo on the cost to build??

mikeyb

Mon, 10/03/2016 - 18:12

cost

Awsome job!!! question? is that a typo on the cost to build??

Foursalmons@gm…

Tue, 07/03/2018 - 17:28

Corner piece

How is the corner piece back line up in the corner?

christy07

Sun, 03/29/2020 - 12:56

I created an account but…

I created an account but where is the plans?

albertmick30

Mon, 08/17/2020 - 07:46

Good

It is superb blog and i really appreciate your blog. It is because i always like the informative blogs. You did a great job and thanks for sharing.I am impressed by your post. It contains very informative data and i gain a lot information from it. It is very useful for me. Thanks for sharing and keep on sharing that type of posts.The Mobile App Developer Dubai provides good service you visit here site https://www.mistersaad.com/